Position change device for polarizing sheet

A polarizer and polarization-maintaining technology, which is applied in nonlinear optics, instruments, optics, etc., can solve problems such as obstacles and shorten the time of assembly line work, and achieve the effect of miniaturization and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

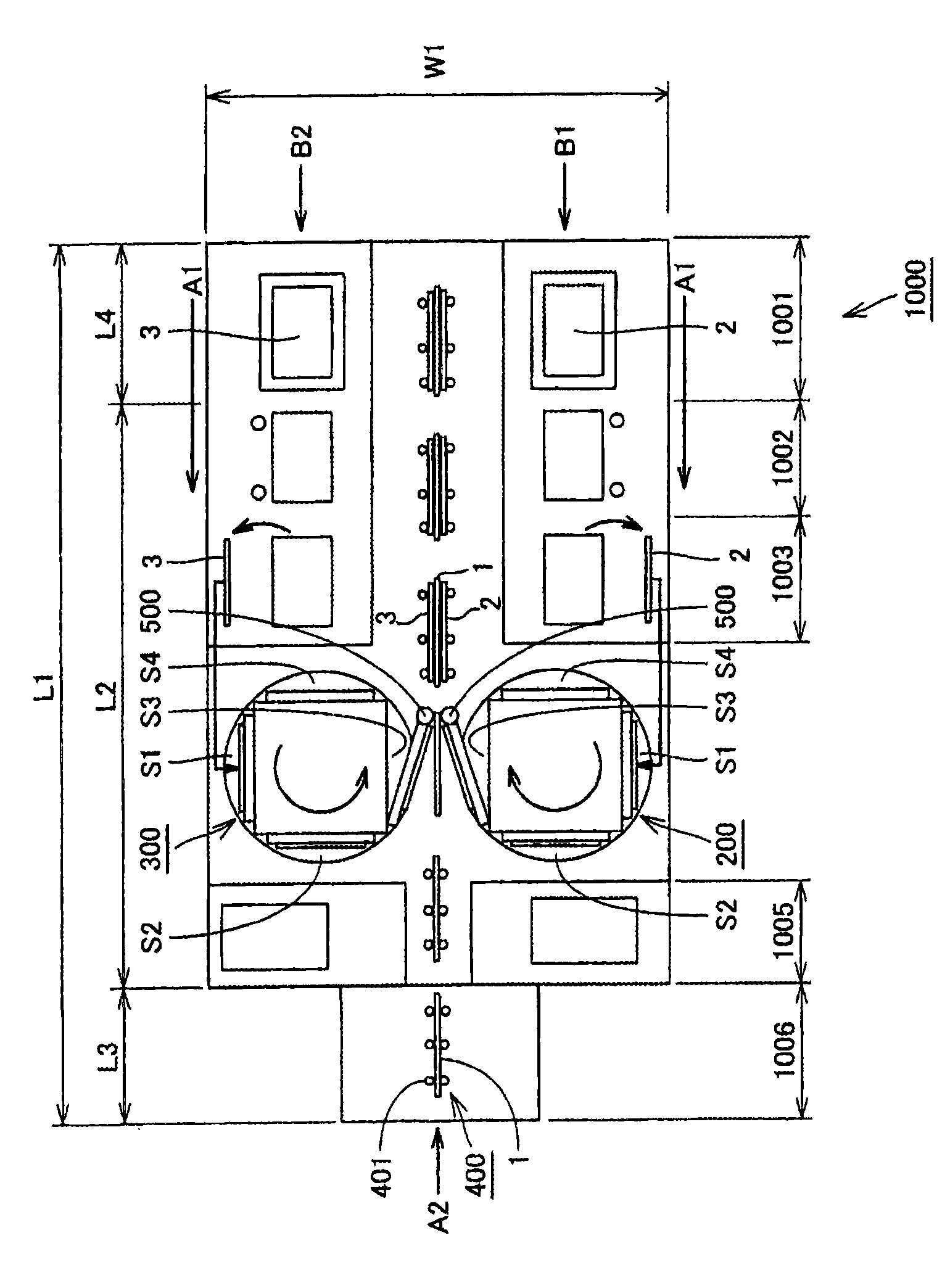

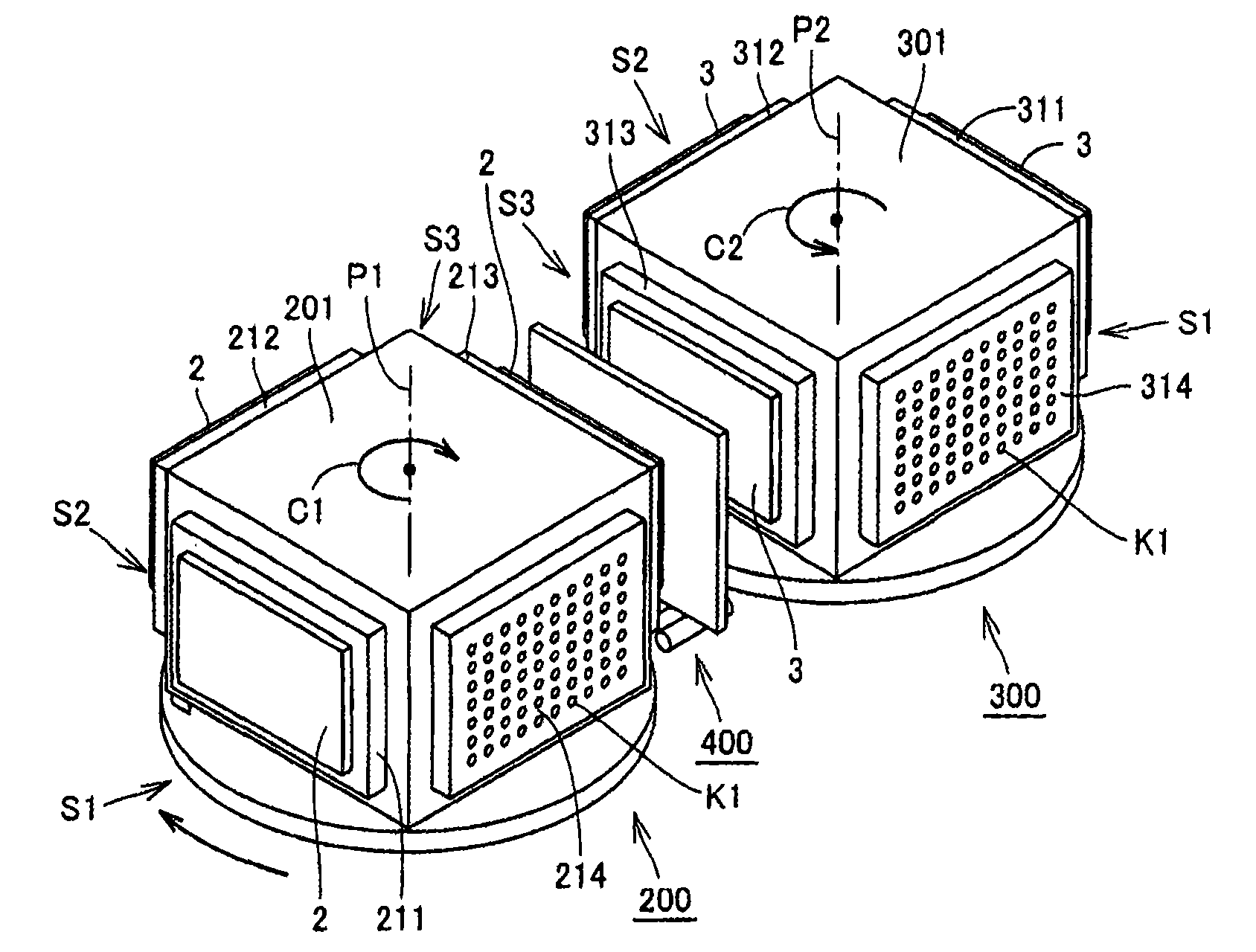

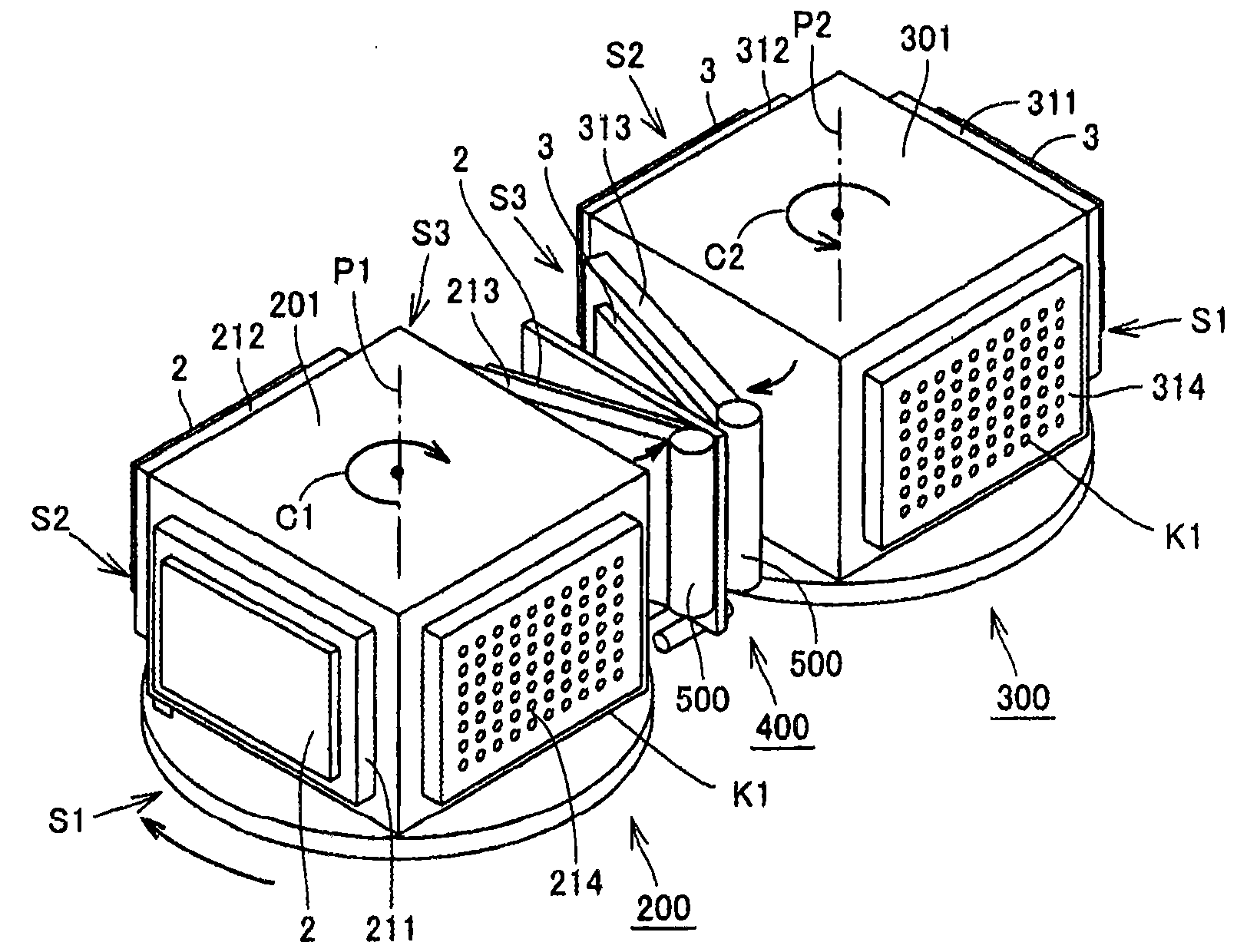

[0034] Next, a polarizer sticking device according to an embodiment of the present invention will be described with reference to the drawings. first, Figure 1 ~ Figure 3 The inventors of this application show a polarizing plate sticking device realized through the development process of the polarizing plate sticking device of the present invention based on the polarizing plate sticking device disclosed in the above-mentioned prior art document 1. figure 1 It is a plan view showing the overall configuration of the polarizer sticking device 1000, figure 2 It is a first perspective view showing the configuration of the first polarizing plate sticking device 200 and the second polarizing plate sticking device 300 employed in the polarizing plate sticking device 1000, image 3 It is a 2nd perspective view which shows the structure of the 1st polarizer sticking apparatus 200 and the 2nd polarizer sticking apparatus 300 used for the polarizer sticking apparatus 1000.

[0035]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com