Stirring pile-grafting machine

A pile planting machine and pile planting technology, applied to sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of not being able to guarantee the verticality of the aggregate, poor machine stability, and easy deviation, and achieve a simple and easy construction process. Operation, compact structure, not easy to dump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

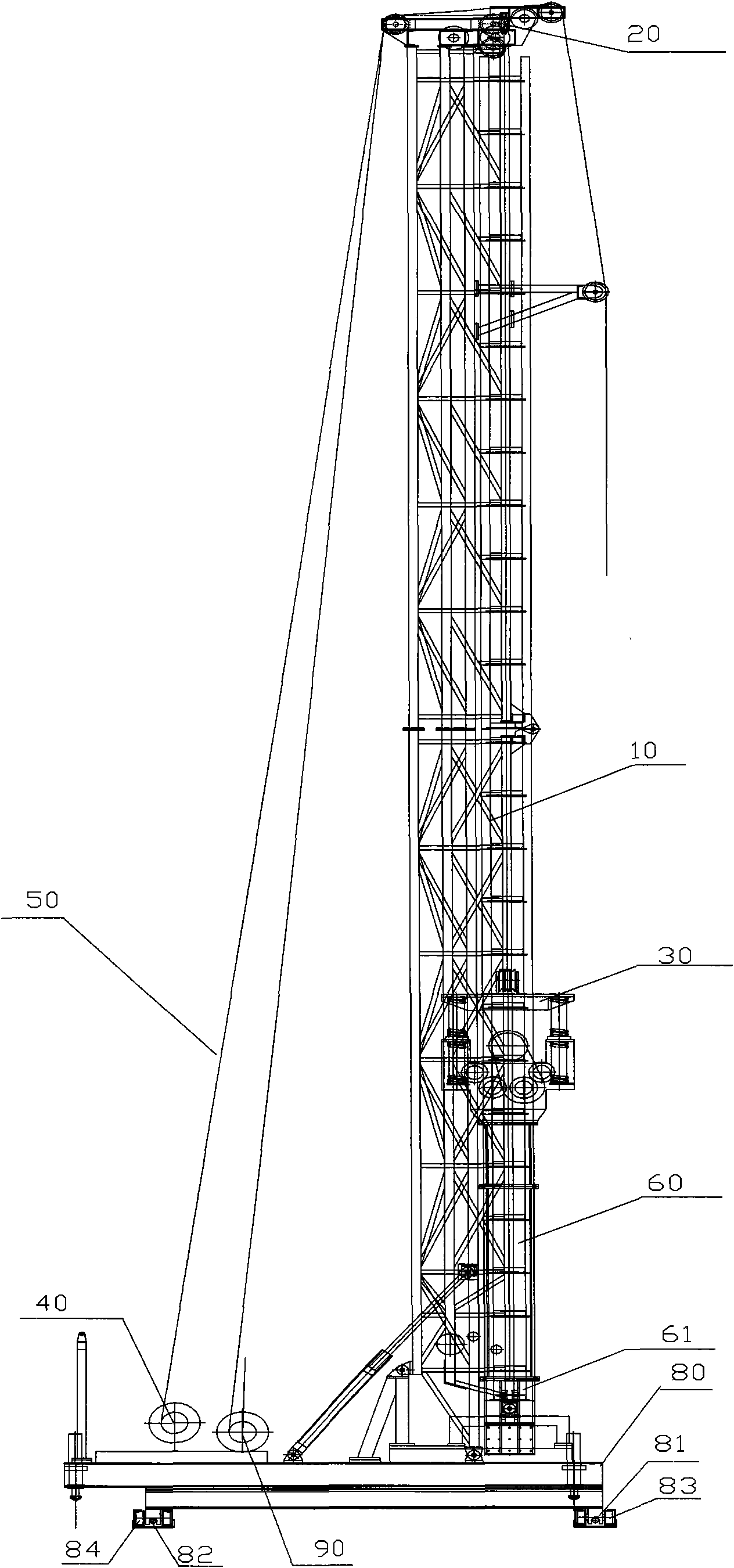

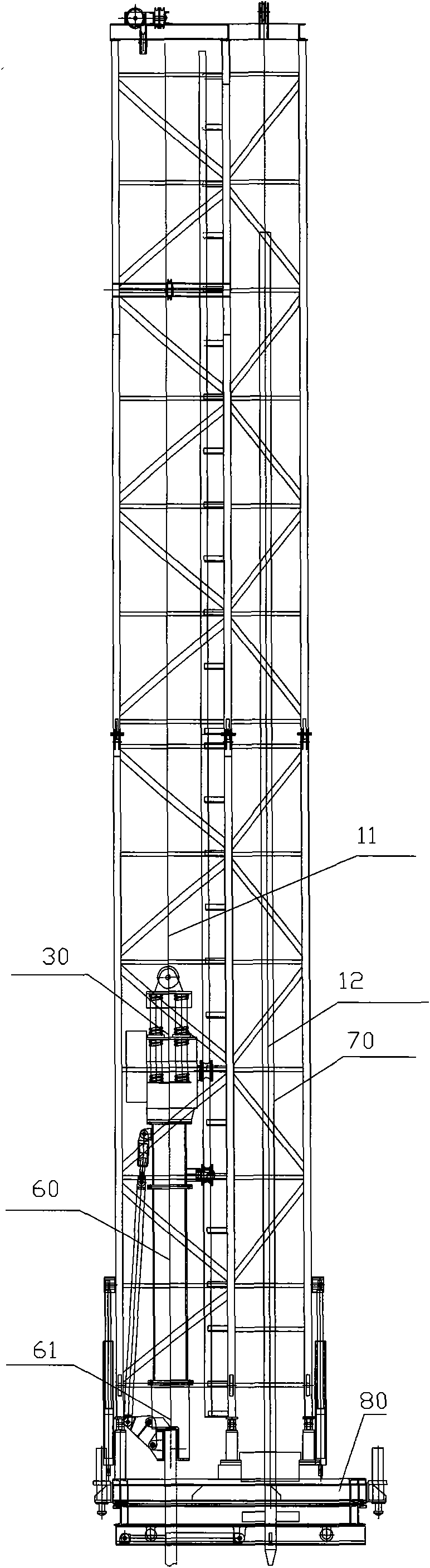

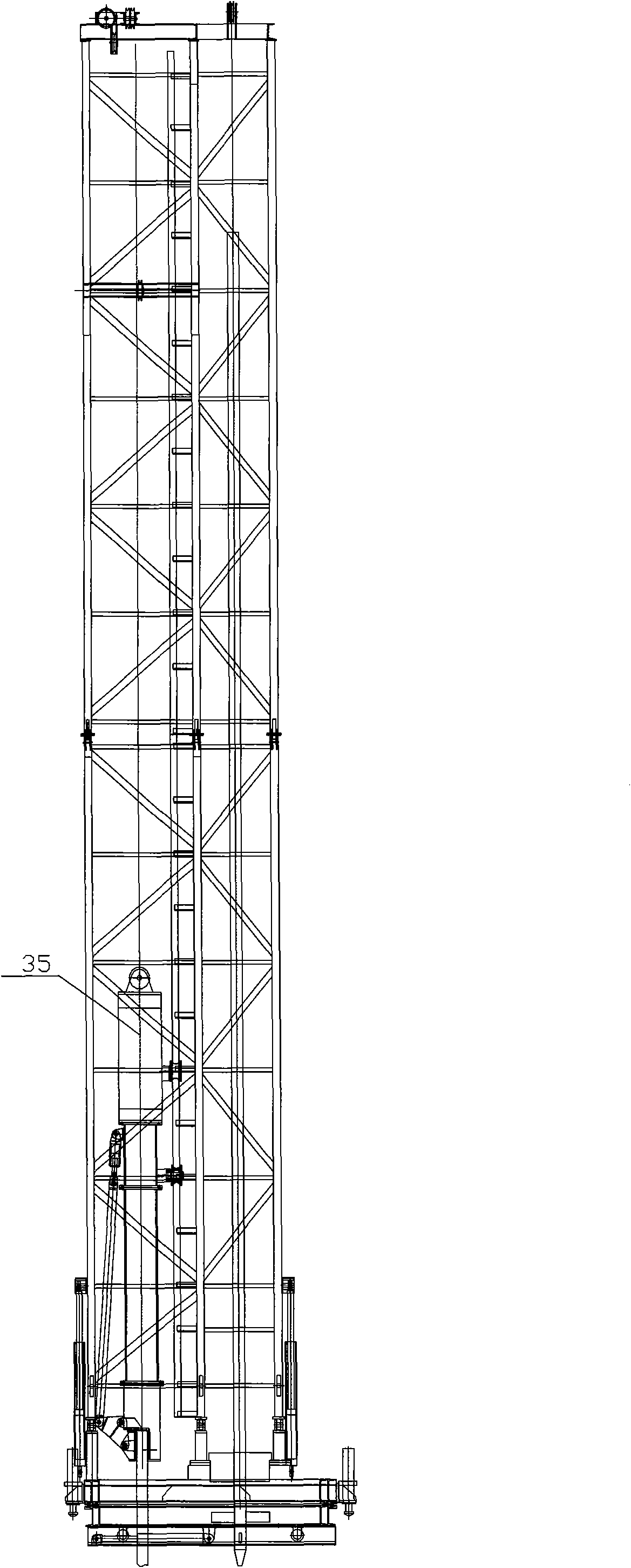

[0021] figure 1 , figure 2 Shown is the first embodiment of the stirring pile driver of the present invention. like figure 1 , figure 2 Shown, the stirring pile machine shown in this embodiment comprises:

[0022] The pile planting device comprises a power hammer, which is a vibratory hammer 30 in this embodiment, a pile planting pile feeder 60, and a power hammer lifter 40, and the top of the pile planting pile feeder 60 is fixedly connected to the top of the vibratory hammer 30. Bottom, the center of the bottom of the pile-planting pile feeder 60 is provided with a pile-planting clamping head 61 for clamping the aggregate to be implanted; the center line of the pile-planting pile feeder 60 and the center line of the vibratory hammer 30 On a straight line, of course, when the construction requirements are low in other embodiments of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com