Hermetic sealing device

A sealing device and compact technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as unstable contact state, achieve the effects of suppressing sliding friction, improving bending, and reducing sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

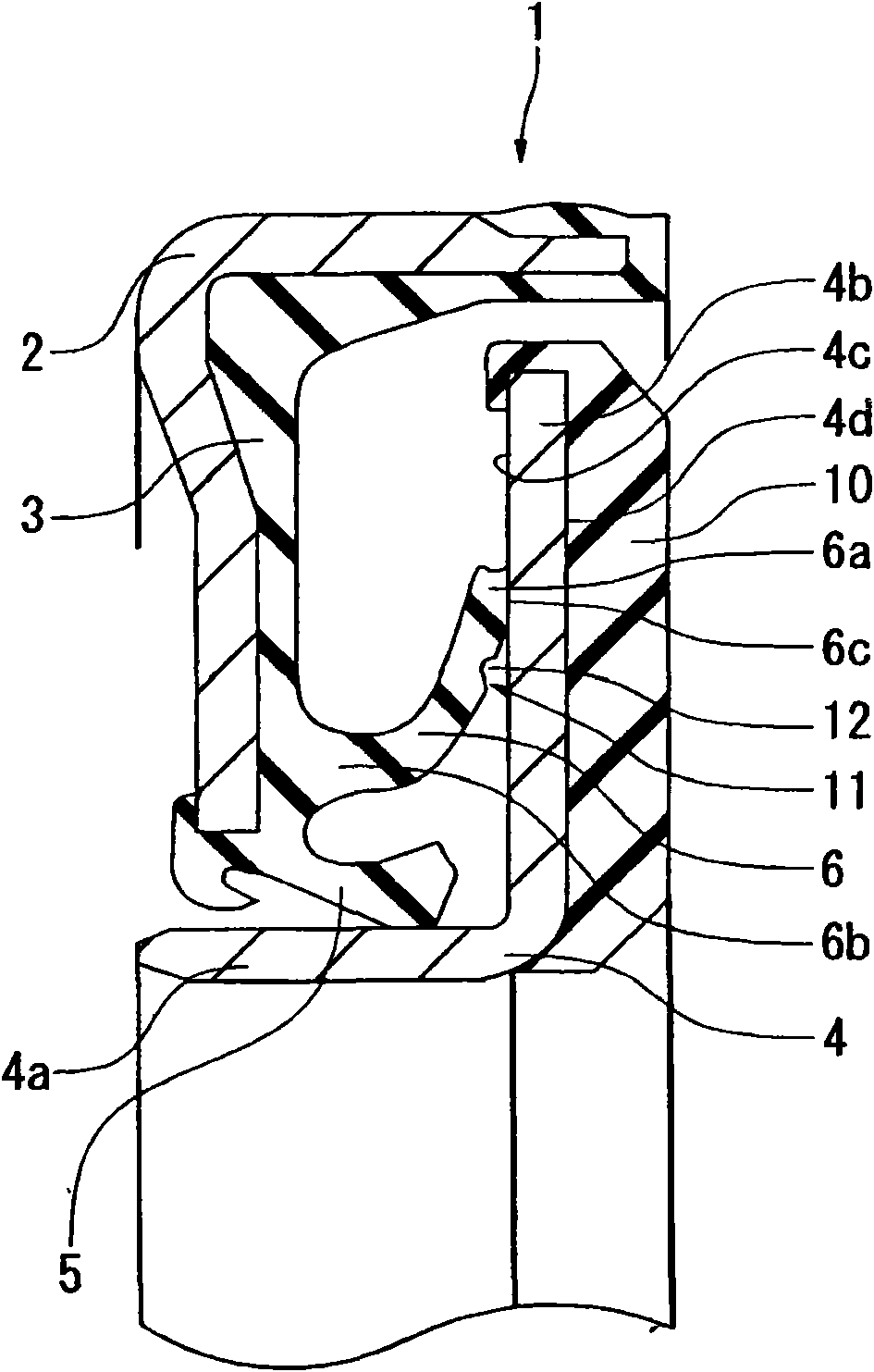

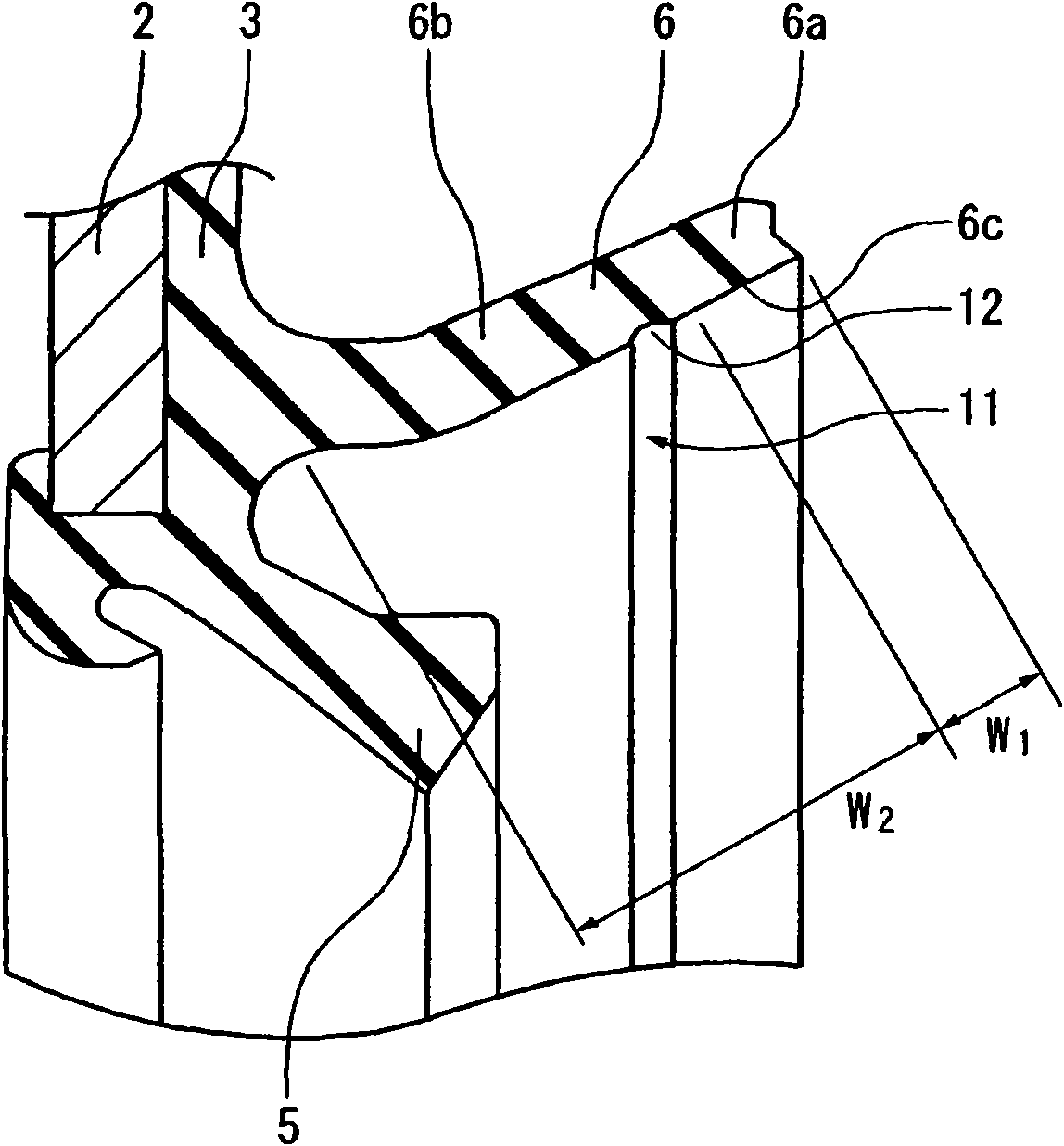

[0056] figure 1 A cross section of a main part of the sealing device 1 of the first embodiment of the present invention is shown.

[0057] The sealing device 1 of this embodiment is used, for example, as a wheel hub bearing seal (hub seal) in a bearing portion of a wheel suspension device for an automobile, and the main lip (radial lip) 5 and the side lip (end face lip) 6 are integrated. Forming, in which the main lip 5 is vulcanized and bonded to the rubber-like elastic body 3 on the mounting ring (metal ring) 2 made of steel such as metal, and slidably and tightly connected to the oil flinger (metal ring) as a sliding opposing member The outer peripheral surface of the cylindrical portion 4a of 4 and the side lip 6 are slidably closely connected to the axial end surface (inner end surface) 4c of the flange portion 4b of the flinger 4 . A magnetic encoder 10 is attached to the outer end surface 4d of the flange portion 4b of the flinger 4 as shown in the figure.

[0058] f...

no. 2 example

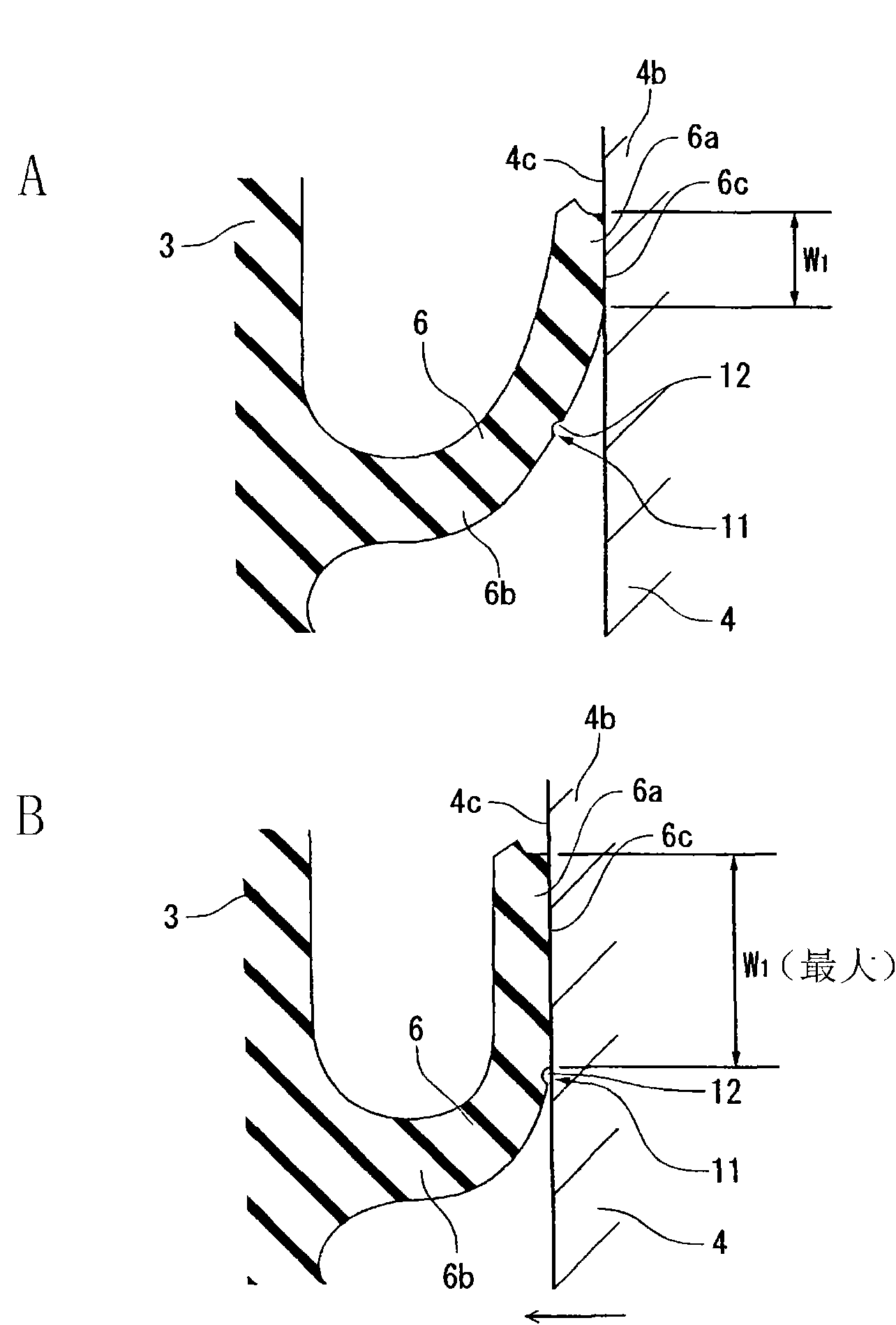

[0064] Figure 4 A cross section of the main part of the sealing device 1 of the second embodiment of the present invention is shown.

[0065] Like the above-mentioned first embodiment, the sealing device 1 of this embodiment is used as a hub bearing seal (hub seal) in, for example, a bearing portion of a wheel suspension device for an automobile, and the main lip 5 and the side lip 6 are integrally formed. , wherein the main lip 5 is vulcanized and bonded to the rubber-like elastic body 3 on the mounting ring 2 made of steel such as metal, and is slidably and tightly connected to the outer peripheral surface of the cylindrical portion 4a of the oil flinger 4 as a sliding opposing member, The side lip 6 is slidably closely connected to the axial end surface 4c of the flange portion 4b of the flinger 4 . A magnetic encoder 10 is attached to the outer end surface 4d of the flange portion 4b of the flinger 4 as shown in the figure.

[0066] Figure 4 It shows the state where t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com