Electromagnetic drive unit

An electromagnetic drive and yoke technology, which is applied in the direction of electromagnets, electrical components, engine components, etc., can solve problems such as coil short circuit and coil disconnection, achieve improved water resistance, excellent water resistance, and suppress short circuit of solenoid components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

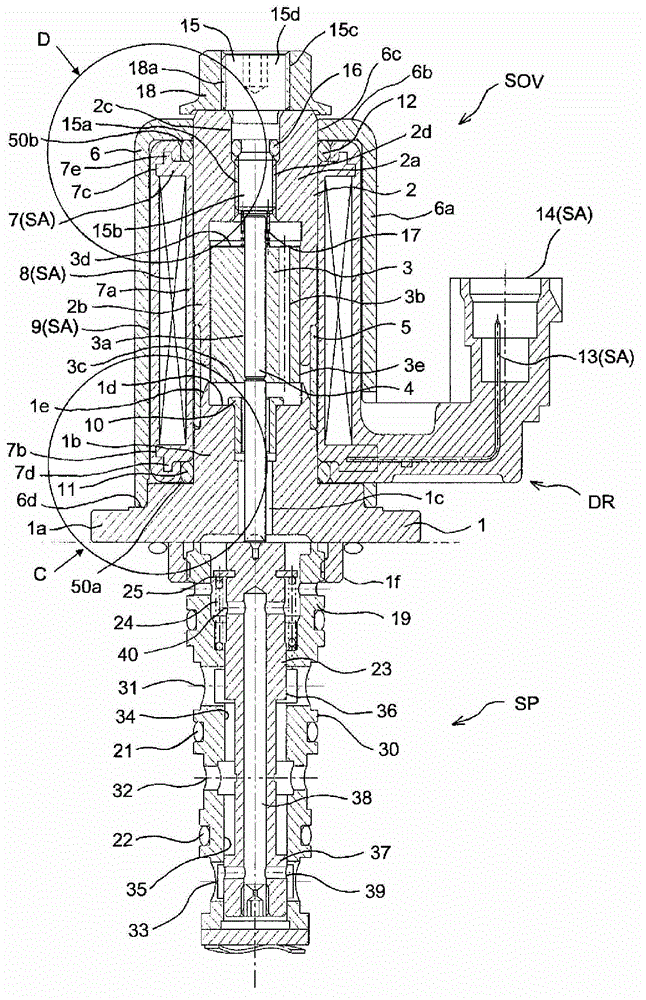

[0036] Below, refer to Figure 1 to Figure 5 , and an embodiment example of the present invention will be described. Such as figure 1 As shown, the electromagnetic drive unit DR according to the embodiment of the present invention is connected to a directional control valve unit SP as a driven device through one end side, and is used as a solenoid valve SOV. The solenoid valve SOV is a 3-port 2-position directional control valve that operates electromagnetically. Valve / throttle valve control, AT car clutch unit, forward / reverse switching clutch control, etc.

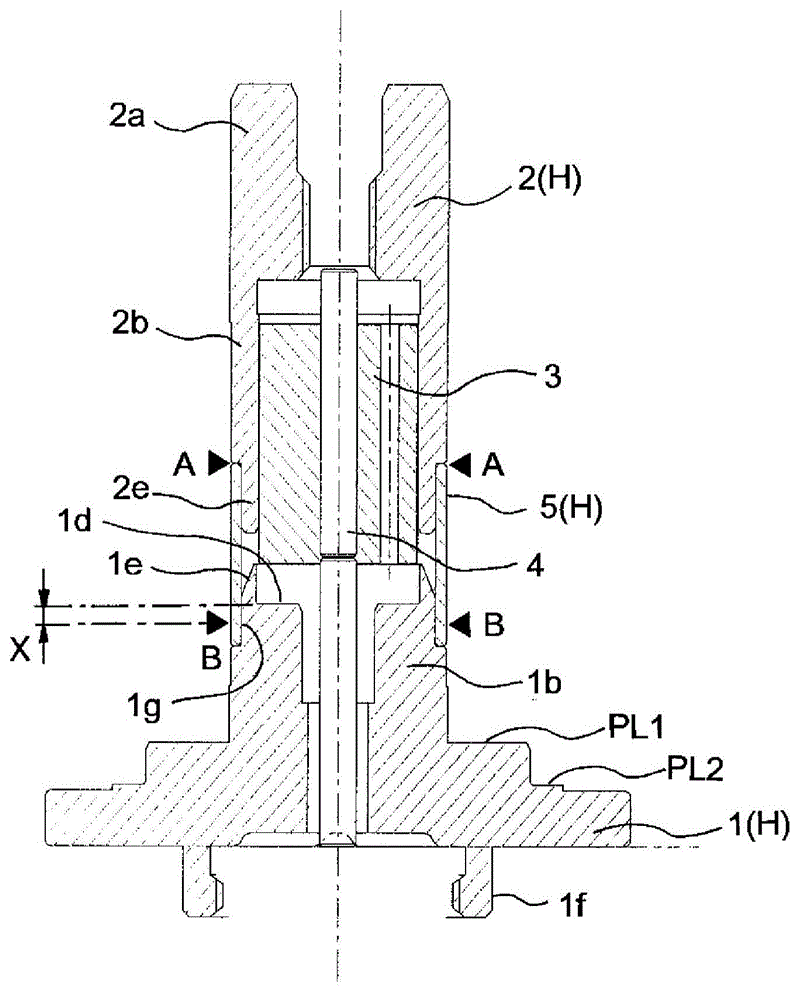

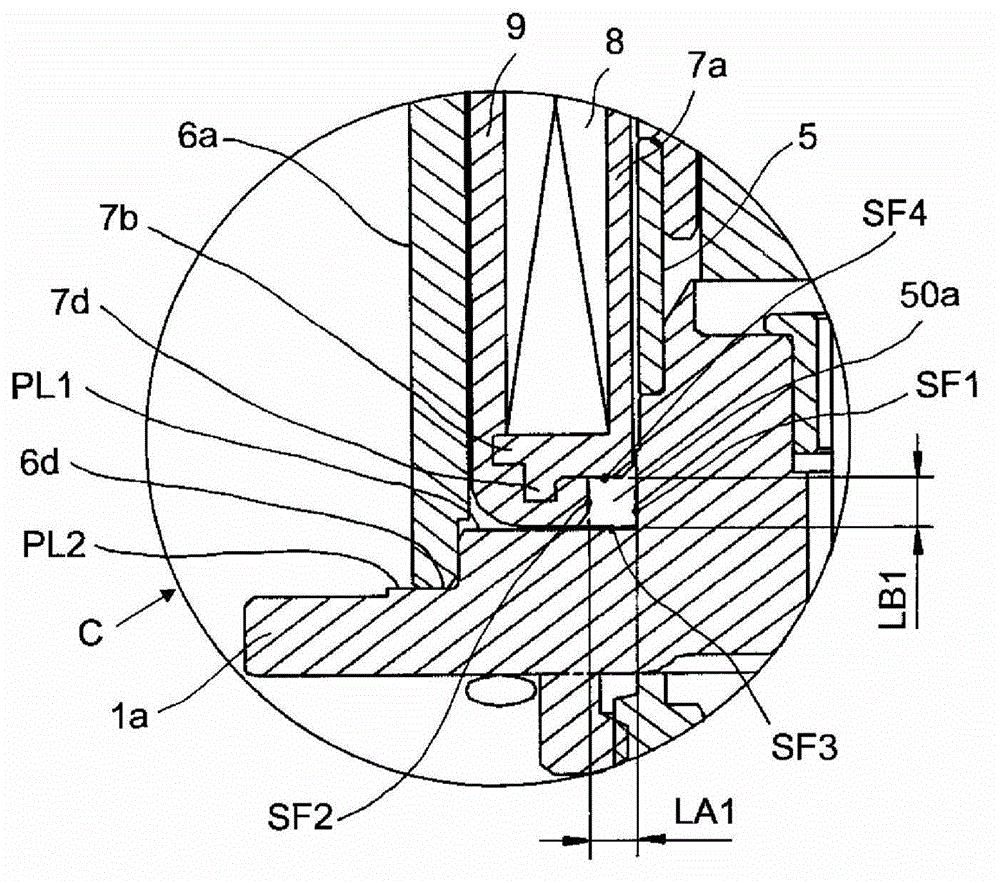

[0037] The electromagnetic drive unit DR has an inner housing H formed of a stator 1, a ring (cylindrical member) 5, and a yoke 2, wherein the stator 1 is made of a magnetic material, the ring 5 is made of a non-magnetic material, and the yoke 2 is made of a magnetic material. The stator 1, the ring 5, and the yoke 2 constituting the inner housing H are arranged coaxially with each other. In addition, the solenoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com