Large braking torque eddy current retarder rotor

An eddy current retarder and braking torque technology, applied in the field of deceleration braking and eddy current retarder rotor, can solve the problems of inability to meet the braking requirements of high-speed trains, small braking torque, high resistivity, etc. , to achieve the effect of large braking torque, improved magnetic field and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

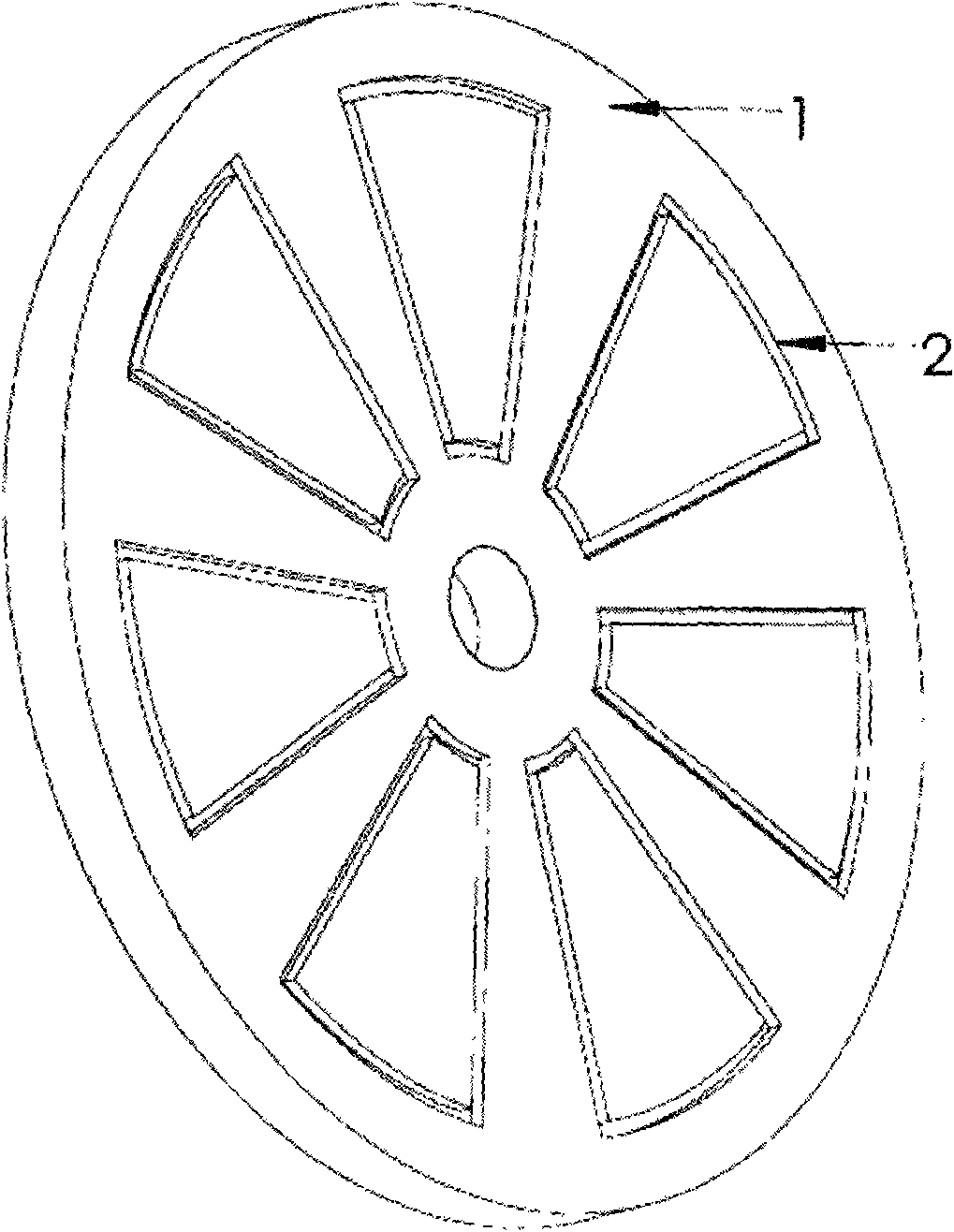

[0014] The invention applies the motor winding theory to the design of the rotor of the large torque eddy current retarder. figure 1 It is a schematic diagram of the present invention. The rotor disk 1 is made of magnetically conductive material. Grooves are processed in the circumferential and radial directions on the rotor disk. Coils 2 processed by good conductors are placed in the grooves. The coils 2 are connected end to end to form a closed loop.

[0015] figure 2 It is a structural schematic diagram of Embodiment 1 of the present invention. The rotor in Embodiment 1 includes five rotor disks, each of which has the same geometric structure, and seven electromagnetic coils are installed in the circumferential direction, and the seven electromagnetic coils are evenly distributed on the rotor disk , so that the force on the rotor at any moment is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com