Laser wire stripping device

A wire stripping device and laser technology, applied in the direction of line/collector parts, equipment for dismantling/armored cables, electrical components, etc., can solve the problems of damage to the insulation layer, high cost of use, deformation of the shielding layer, etc., and achieve the finished product High efficiency, low processing cost, and stable optical power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

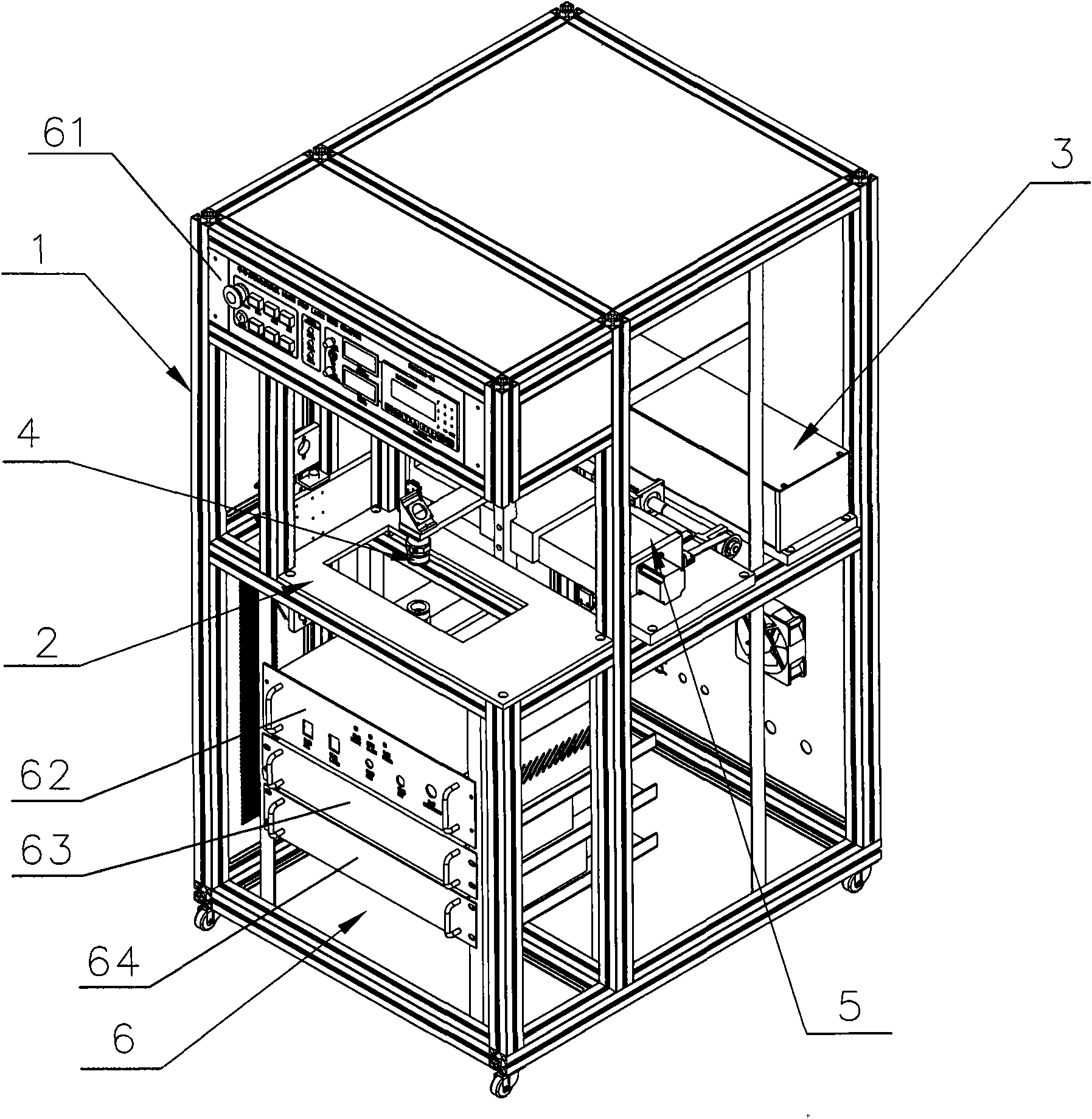

[0034] Such as Figure 1-9 As shown, a kind of laser wire stripping device of the present invention comprises frame 1, working platform 2, laser generation chamber 3, laser head 4, motion mechanism 5 and control mechanism 6, and the laser light that laser generation chamber 3 produces passes mirror group 7 reflection and transmission to the laser head 4 to realize the laser optical path transmission, the movement mechanism 5 controls the laser head 4 to realize the wire stripping action, and the upper laser head 4 and the lower laser head 4 of the laser head 4 are arranged symmetrically with the working platform 2 as the symmetrical surface; The mechanism 5 includes a Y-axis moving part 51 to realize forward and backward movement, an X-axis moving part 52 to realize left and right movement, and an up and down laser switching structure 53 to realize up and down movement; the Y-axis moving part 51 includes a Y-axis guide rail 51a, a moving platform 51b and a Y-axis The drive mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com