Thermo-compensation current sensing head as well as alternate current measurement method and system

A temperature compensation, sensor head technology, applied in the direction of measuring current/voltage, thermometer, measuring device, etc., can solve the problems of fiber birefringence, affecting sensor performance, vibration and bending, etc., achieve good electrical insulation, improve sensitivity and Range, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

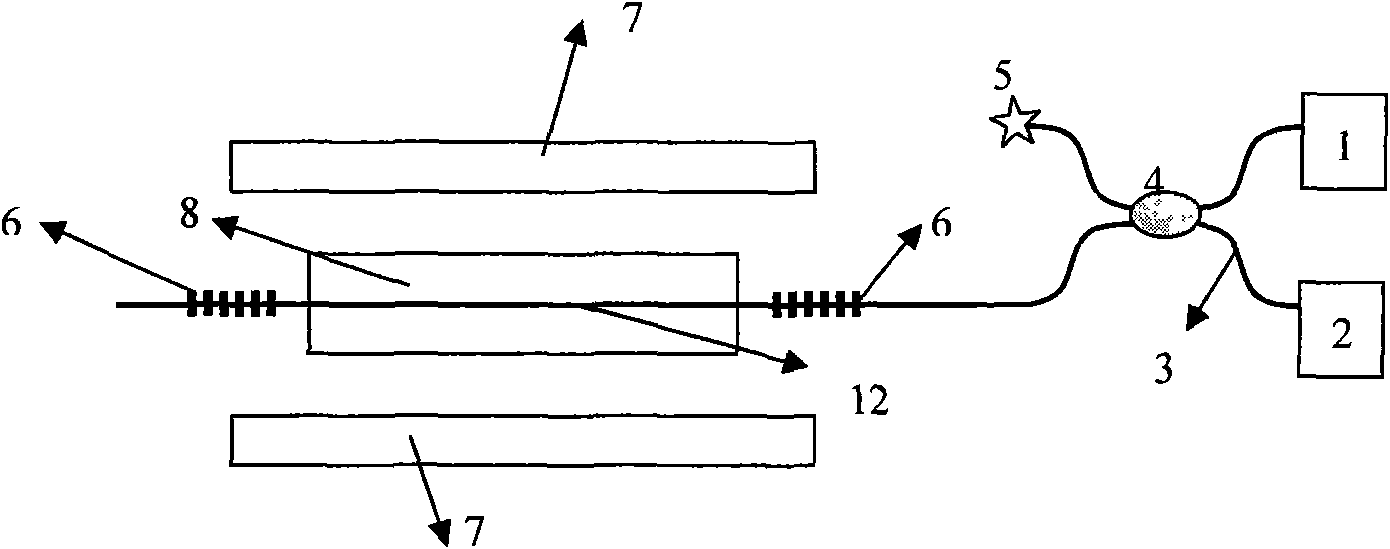

[0028] Embodiment 1: see attached figure 1 , is a structural schematic diagram of the fiber grating FPI current measuring device. The fiber grating FPI12 is pasted on the magnetostrictive material 8, and the permanent magnet 7 is fixed on both sides of the magnetostrictive material 8 in parallel. The refractive index matching liquid 5 is connected, and the two ports on the other side of the fiber coupler 4 are respectively connected with the monochromatic light source 1 and the photodetection device 2 .

[0029] The F-P cavity of the fiber grating FPI12 is constrained by the magnetostrictive material 8, and the two fiber grating parts 6 are placed freely; the reflectivity of the fiber grating FPI12 is less than 5%.

[0030] The monochromatic light source emits a wavelength of λ and a light intensity of I 0 The optical signal is transmitted to the fiber grating FPI sensor probe through the coupler. Since the reflectivity of the fiber grating FPI is less than 5%, the reflecte...

Embodiment 2

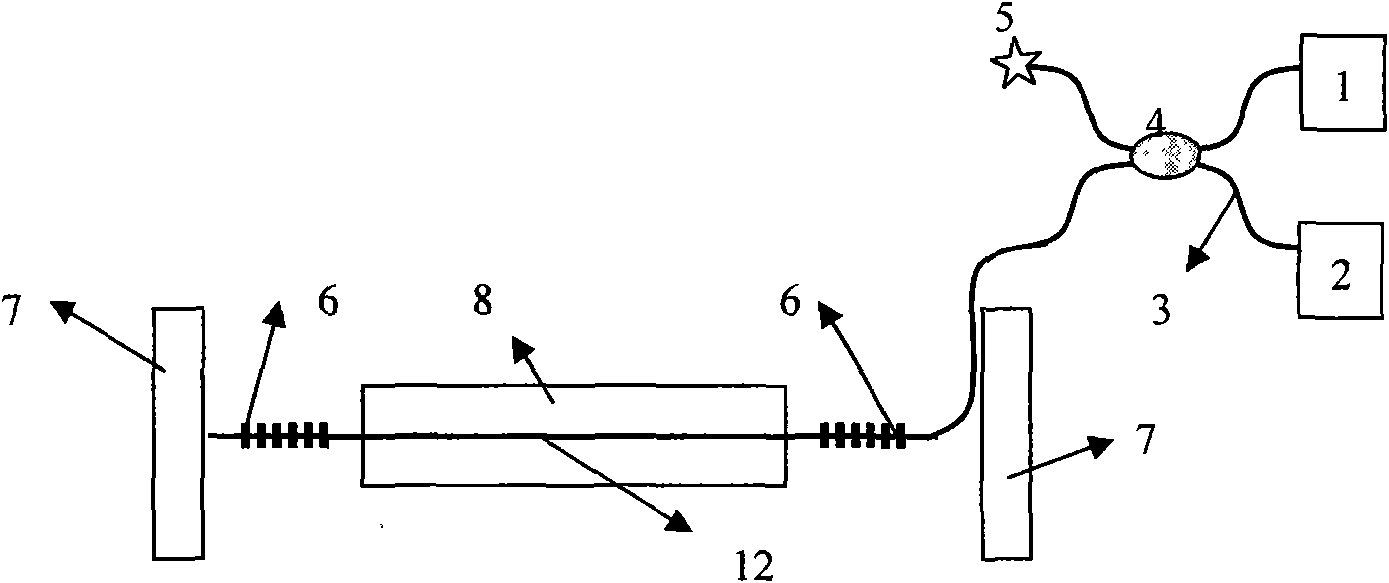

[0045] Embodiment 2: see attached figure 2 , the difference from Embodiment 1 is that the two permanent magnets 7 are respectively fixed at both ends of the magnetostrictive material.

Embodiment 3

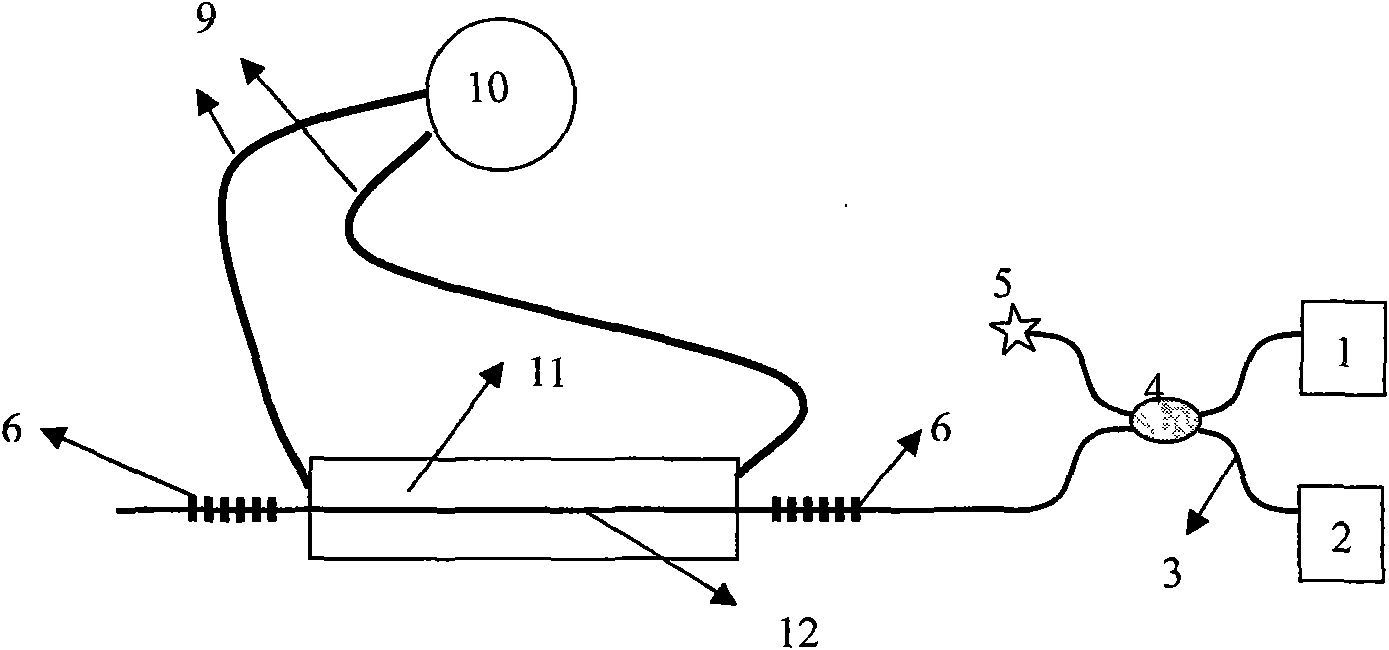

[0046] Embodiment 3: see attached image 3 , the difference from Embodiment 1 is that the driving element that makes the cavity length of the fiber grating FPI12 vary periodically includes a transmission line 9 , a piezoelectric ceramic 11 and a mutual induction coil 10 . The output of the mutual induction coil 10 is connected to the piezoelectric ceramic 11 through the transmission line 9 .

[0047] The mutual induction coil converts the current in the busbar into a voltage, and loads it on the piezoelectric ceramic through the transmission line. Driven by the voltage, the piezoelectric ceramic deforms and acts on the F-P cavity of the fiber grating, causing the F-P cavity of the fiber grating to deform.

[0048] The realization device of this method is that the fiber grating FPI of the fiber grating Fabry-Perot interferometer is pasted on the magnetostrictive material, and it is connected with a port of the fiber coupler through a single-mode fiber, and the monochromatic li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com