Paper glass handle-sticking machine

A handle sticking machine and paper cup technology, which is applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of inaccurate positioning, poor stability, and complicated structure of the positioning mechanism of the cup body, and achieve accurate positioning and high production effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

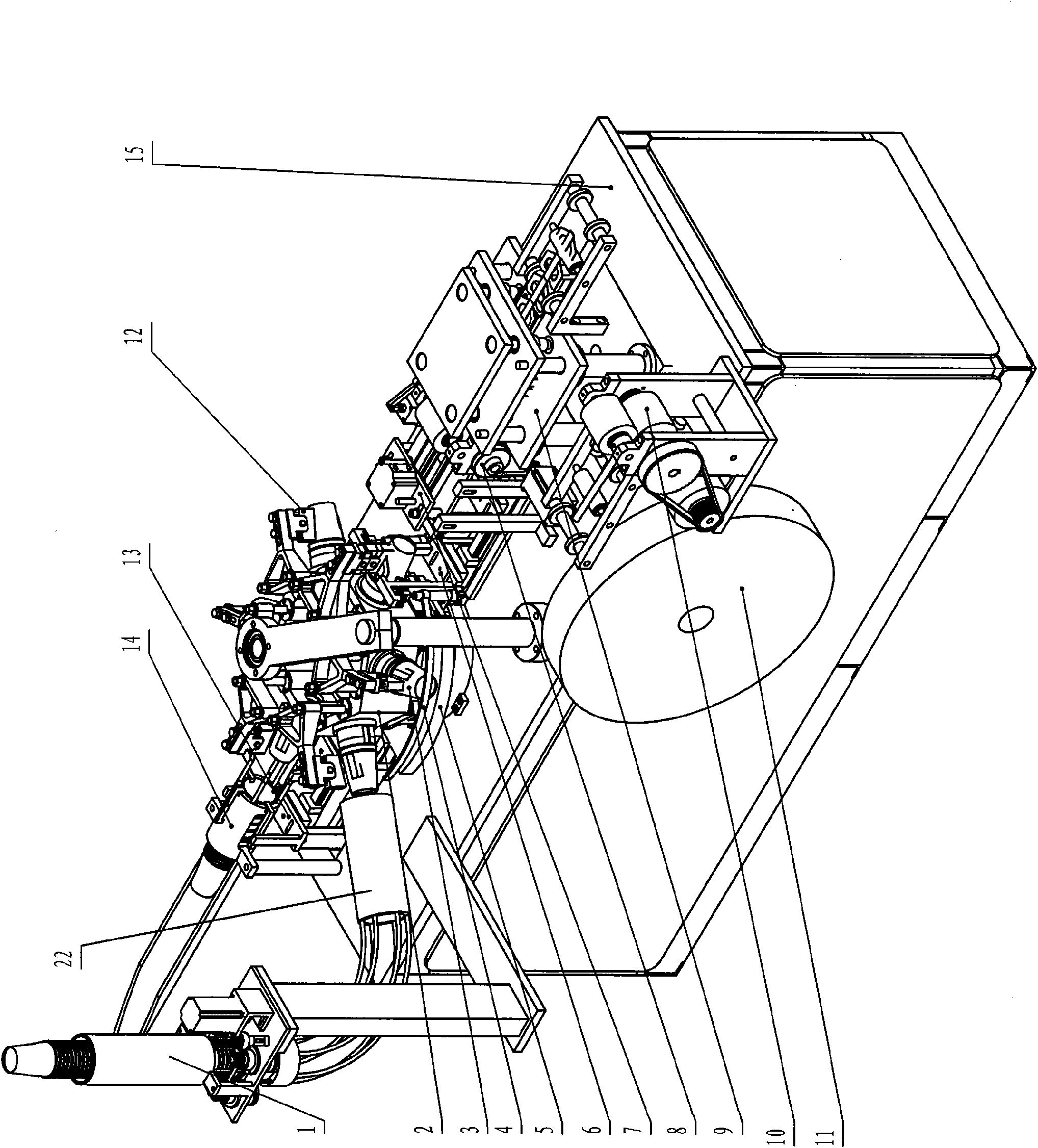

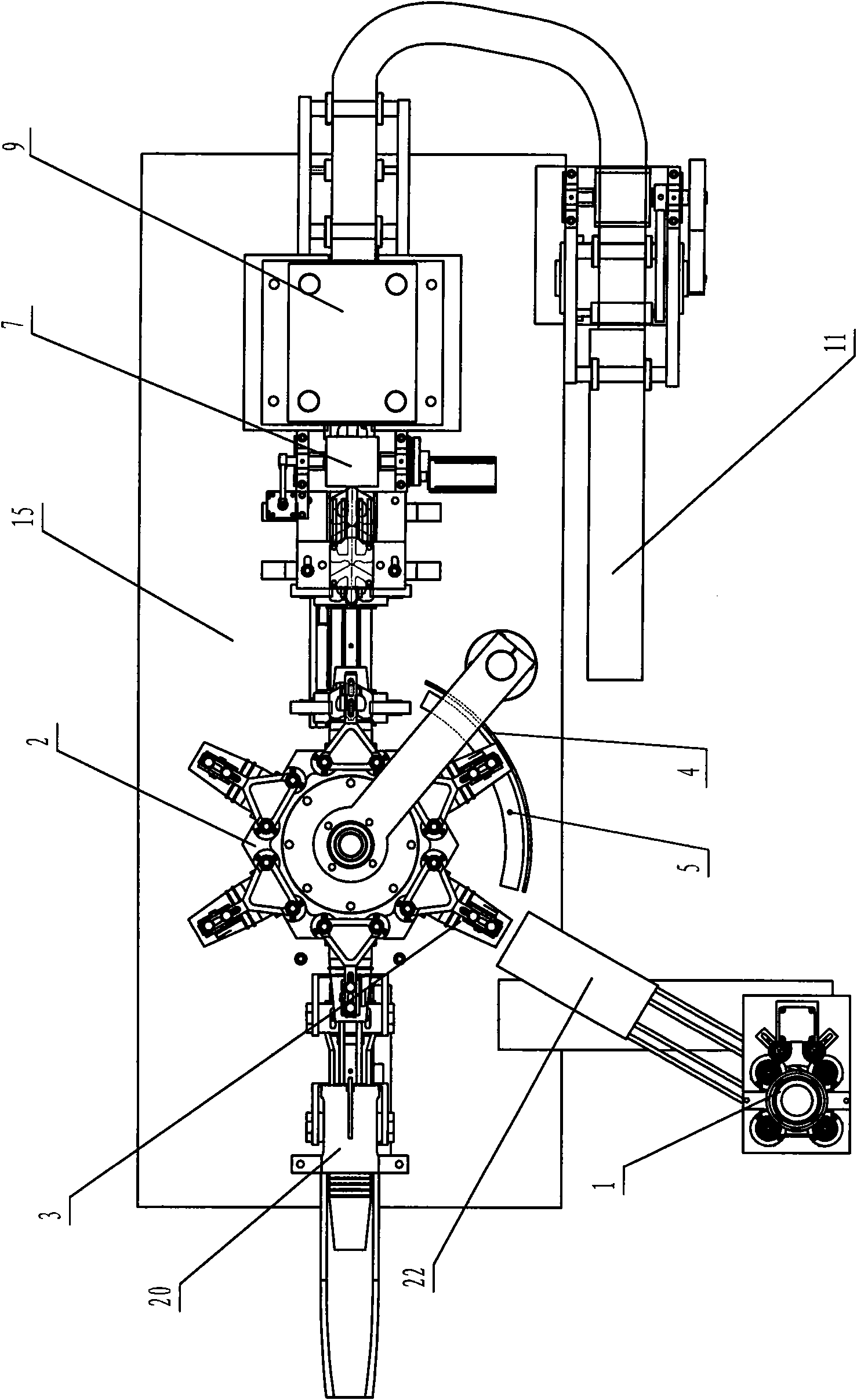

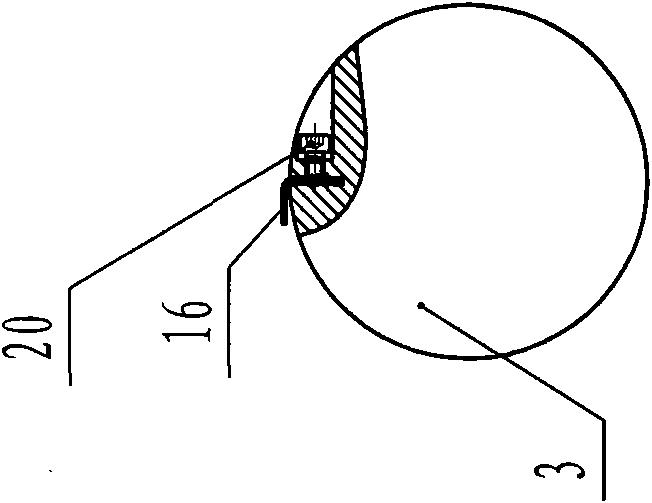

[0015] With reference to the accompanying drawings, this paper cup handle sticking machine includes a frame 15, a cup feeding mechanism, and a turntable 2. A cup mold 3 is arranged around the turntable 2. When the cup mold 3 rotates with the turntable 2, it has a cup feeding station. , a positioning station and a pressing station, on the frame 15 are provided with a paper feeding belt mechanism 10, a cup handle die-cutting mechanism 9, a cup handle cutting mechanism 7, and a belt gripper is provided on one side of the turntable 2 The paper handle delivery manipulator 6 of the mouth 19, the other side is provided with a cup output manipulator 21, and a pressing device for sticking the cup handle to the surface of the paper cup is provided above the cup mold 3; at the positioning station, the cup mold 3 is provided with a paper cup friction strip 5; a limit strip 4 is provided under the cup bottom side of the cup mold 3 at the positioning station; a spring leaf 16 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com