Plate stretch-forming machine

A drawing machine and plate technology, applied in the field of mechanical engineering, can solve the problems of uneven distribution of tensile stress and tensile strain of parts, lower material utilization rate, and high manufacturing cost, so as to improve material utilization rate, reduce manufacturing cost, and reduce load. The effect of reasonable path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

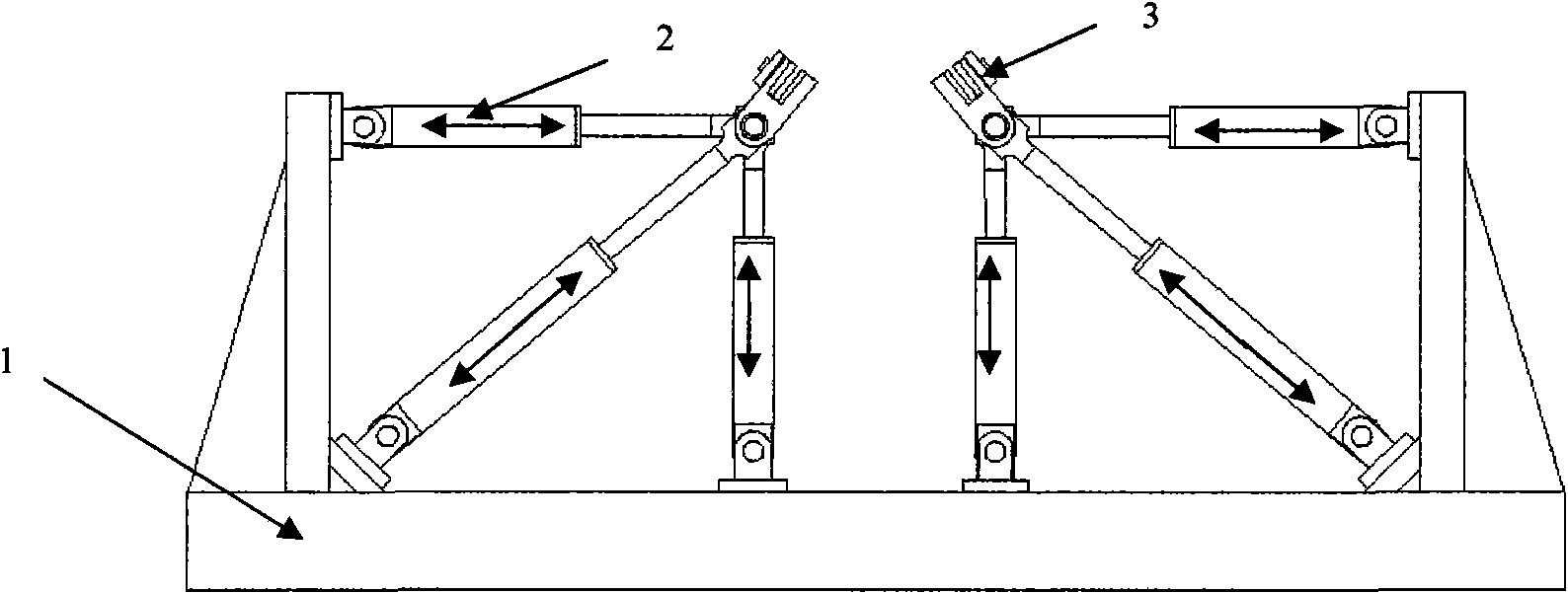

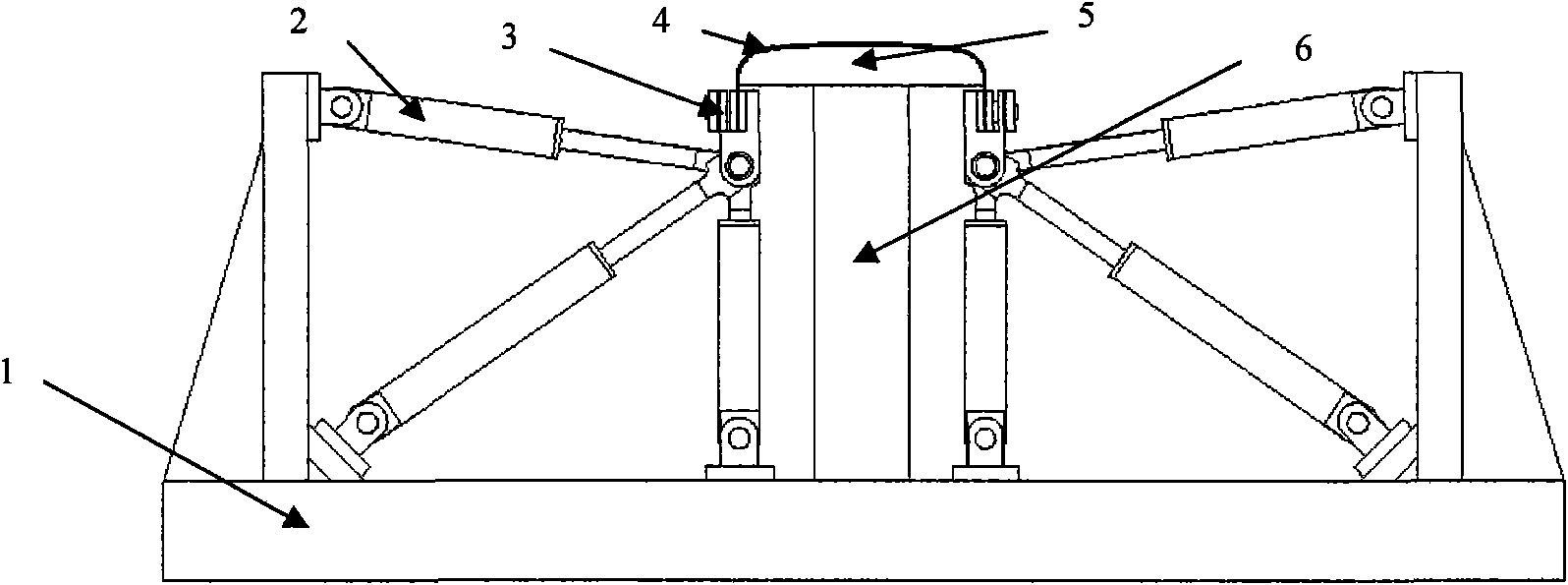

[0043] Fig. 1 is a schematic diagram of a drawing machine, which is mainly composed of a frame 1 and a row of five pulling mechanisms and clamping mechanisms 3 on the left and right sides of the frame 1. The material pulling mechanism is made up of three hydraulic cylinders 2, one is arranged horizontally, one is arranged vertically, and the other is arranged obliquely. One end of the hydraulic cylinder 2 is respectively hinged with the frame 1, and the other end is jointly hinged with the clamping mechanism 3. By changing the hydraulic pressure of the hydraulic cylinder 2, the stroke of the hydraulic cylinder 2 can be changed, and the angle between the hydraulic cylinders 2 can also be changed, thereby changing the position and the pulling direction of the clamping mechanism 3. The hydraulic pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com