Activated carbon hollow fiber polysulfone membrane and preparation method thereof

A technology of activated carbon and polysulfone membrane, which is applied in the field of hollow fiber polysulfone membrane and its preparation, can solve the problems that cannot meet the requirements of modern complex water quality treatment, cannot solve the problem of high-pollution water quality wastewater treatment, and reduce the diffusion flux. Achieve the effects of shortened hydraulic retention time, good spinnability, and increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

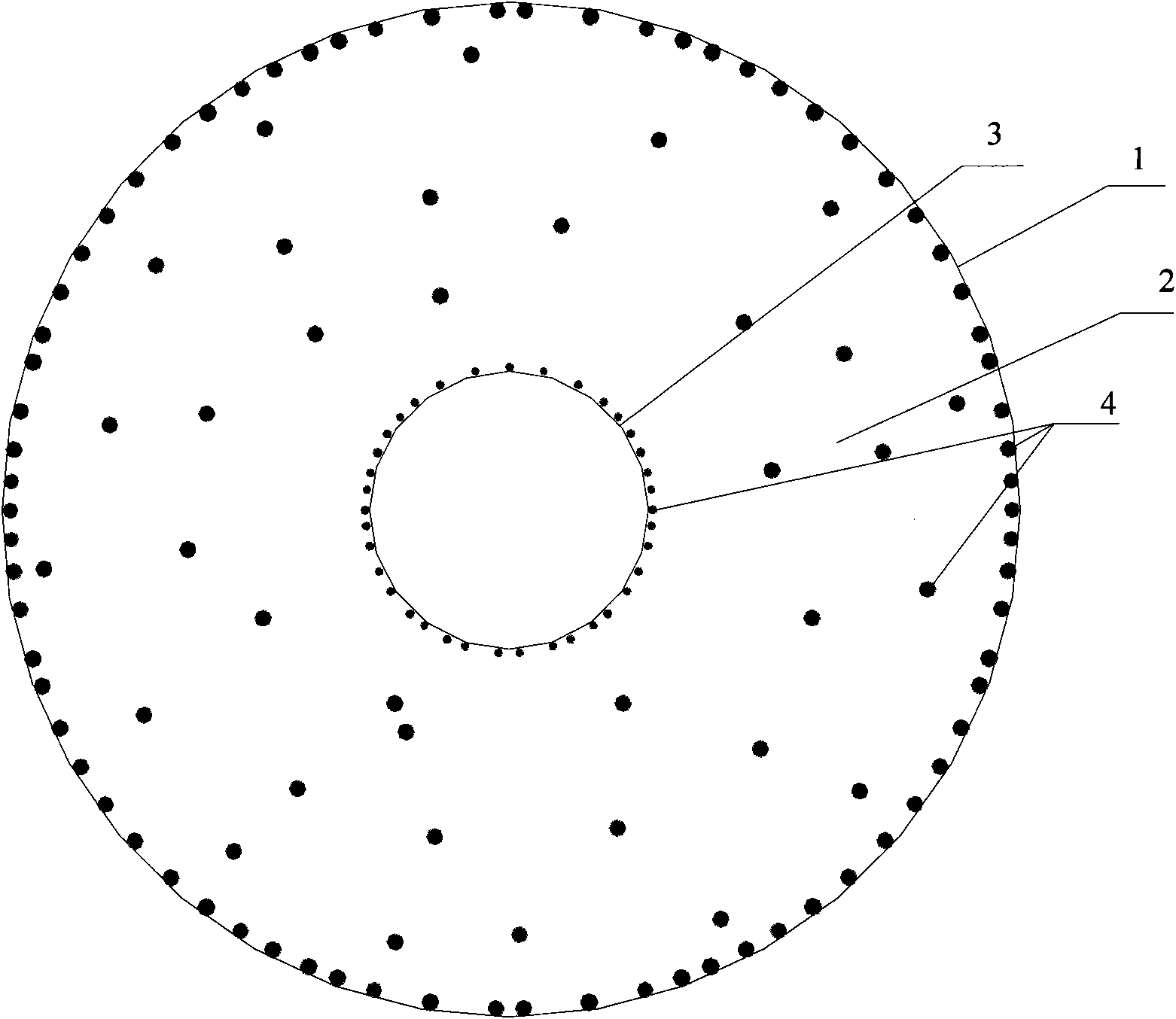

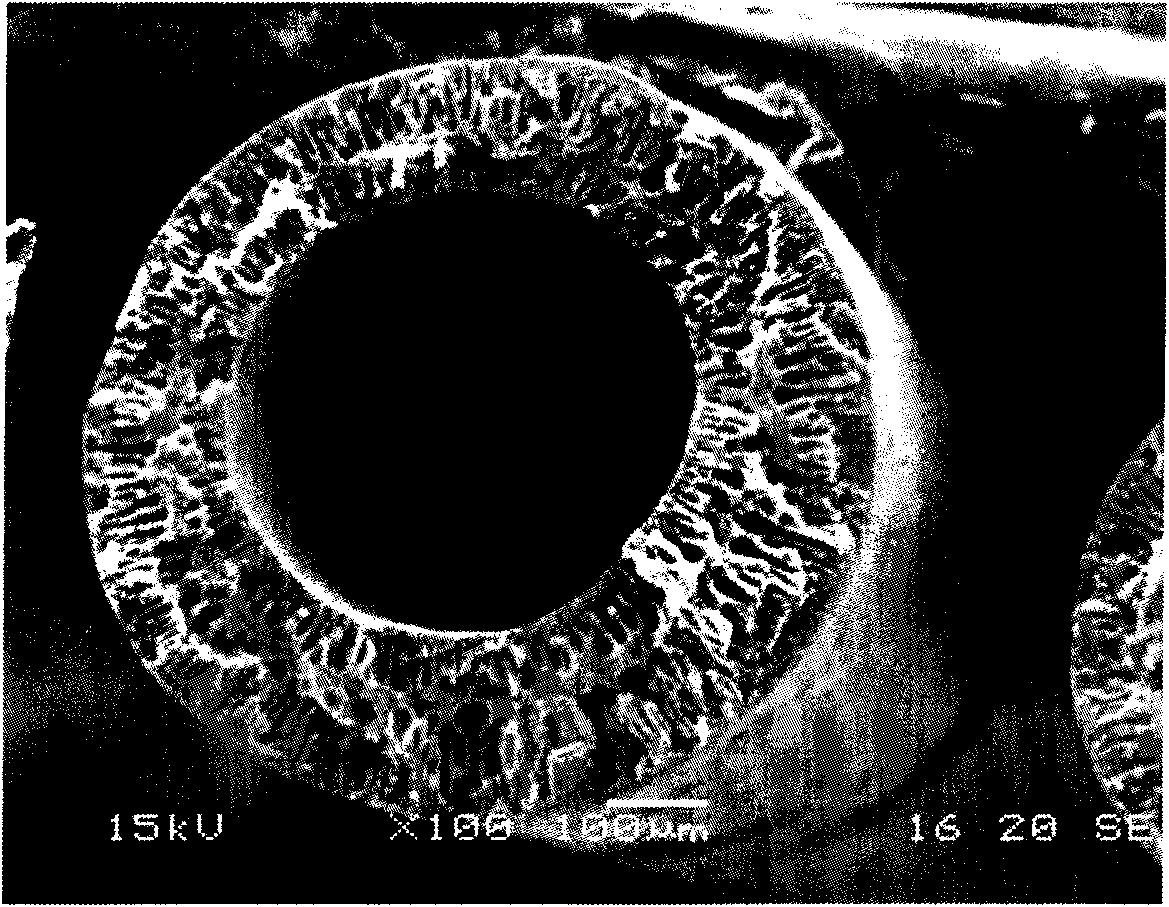

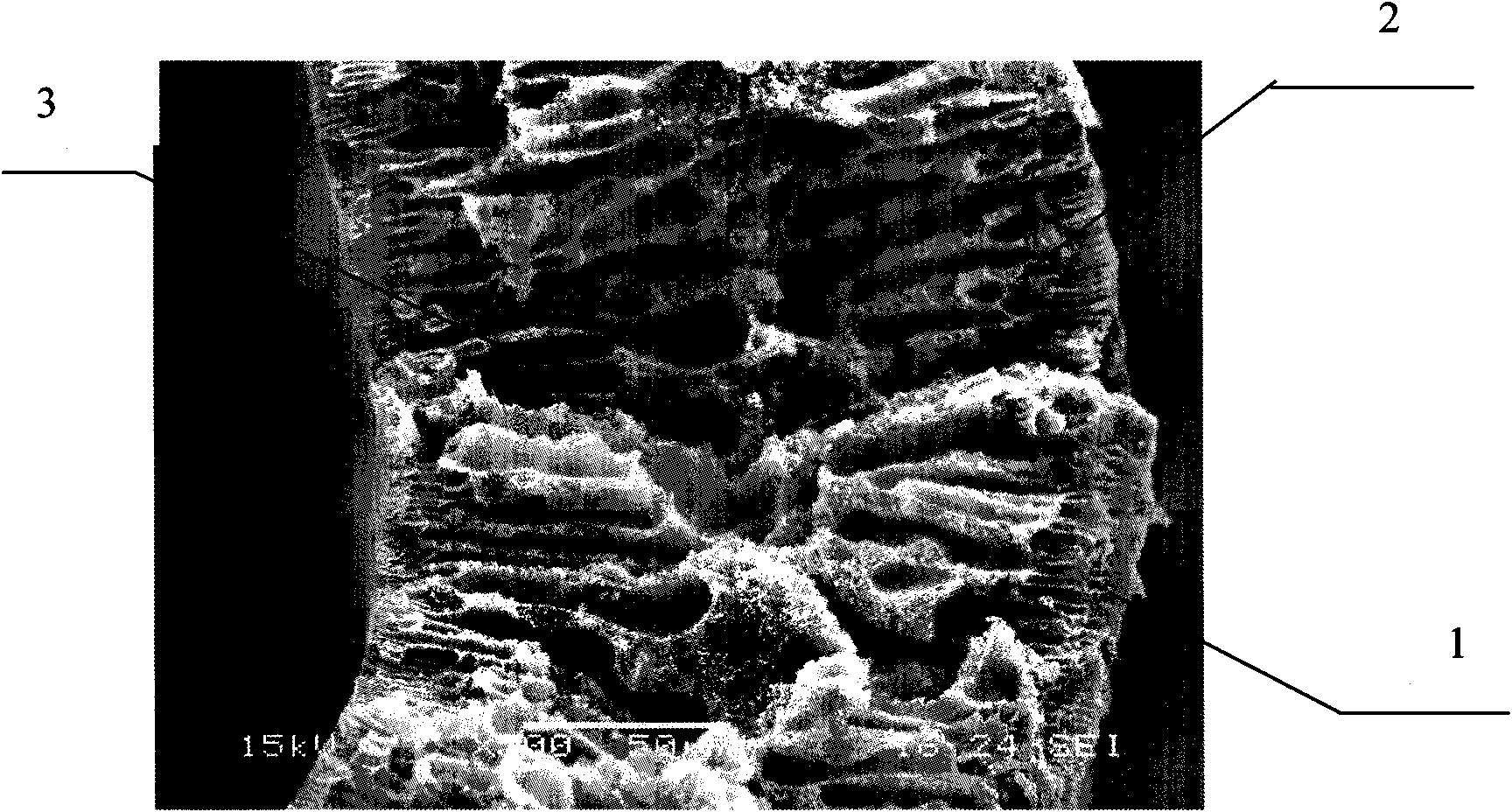

[0019] This embodiment is an activated carbon hollow fiber polysulfone membrane suitable for biological treatment of high-concentration 4-chlorophenol wastewater. The general-purpose, low-cost polymer polysulfone is used as the raw material. It is a transparent bisphenol A polysulfone, which is formed by polycondensation of bisphenol A and 4,4-dichlorodiphenyl sulfone. The molecular weight is 100,000-116,500, and the glass transition temperature is 180~190℃, heating deformation temperature 170~175℃, tensile strength 75MPa, flexural modulus 2650MPa. Activated carbon particles supplemented with coconut shells have an average particle size of less than 10μm and a specific surface area of 1104m 2 / g, void volume 0.92cm 3 / g, 1-methyl-2-pyrrolone as a solvent, the three are mixed in a mass ratio of 1:4:5. First dissolve various raw materials at a temperature of 80°C, and then spin activated carbon hollow fiber polysulfone membranes by wet spinning process: the wet spinning leng...

Embodiment 2

[0021] This embodiment is an activated carbon hollow fiber membrane suitable for biological treatment of high-concentration phenol wastewater. The composition and preparation method of the membrane material are equivalent to those of the previous example, but the dosage of activated carbon particles is increased, and the mass ratio of polymer polysulfone, 1-methyl-2 pyrrolidone, and activated carbon particles is adjusted to 1:5: 5. The obtained hollow fiber membrane also has a three-layer asymmetric structure, but the outer surface of the membrane is denser, and the distribution of activated carbon particles in the membrane is more concentrated and uniform, so that the adsorption characteristics of the hollow fiber membrane itself are further strengthened, and the concentration of phenol as high as 1000mg / L Wastewater treatment efficiency can also reach 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com