Suspended type ultrafine dry powder extinguishing installation

A fire extinguishing device and ultrafine dry powder technology, which is applied in the field of suspended ultrafine dry powder fire extinguishing devices, can solve the problems of unsightly, large volume, complex structure, etc., and achieve the effect of fast response and low power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

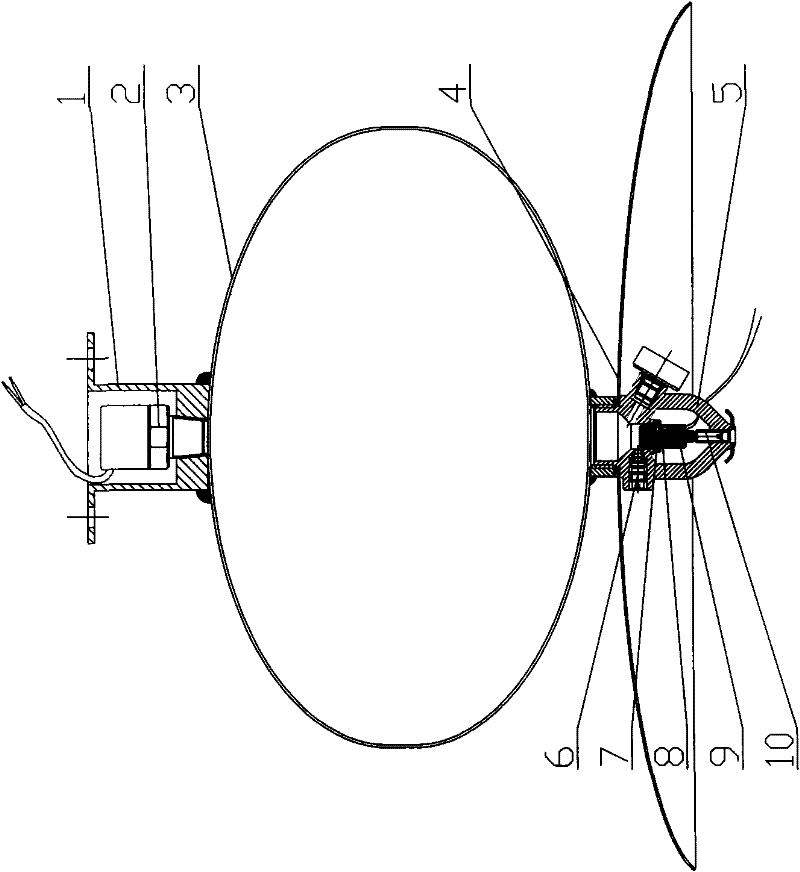

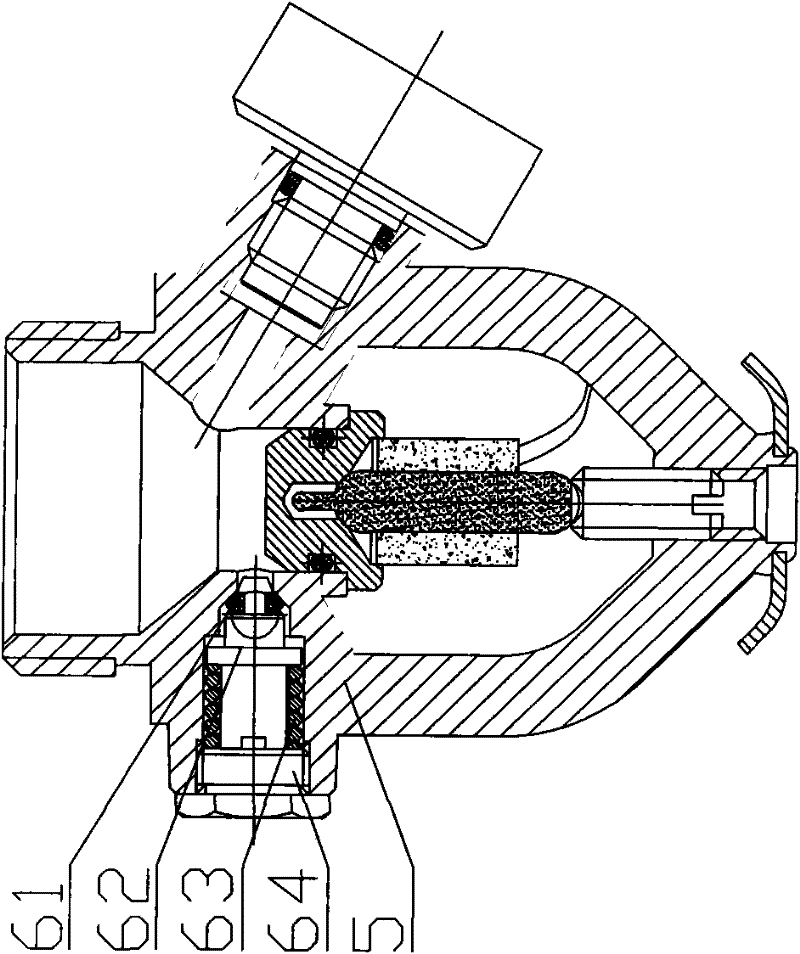

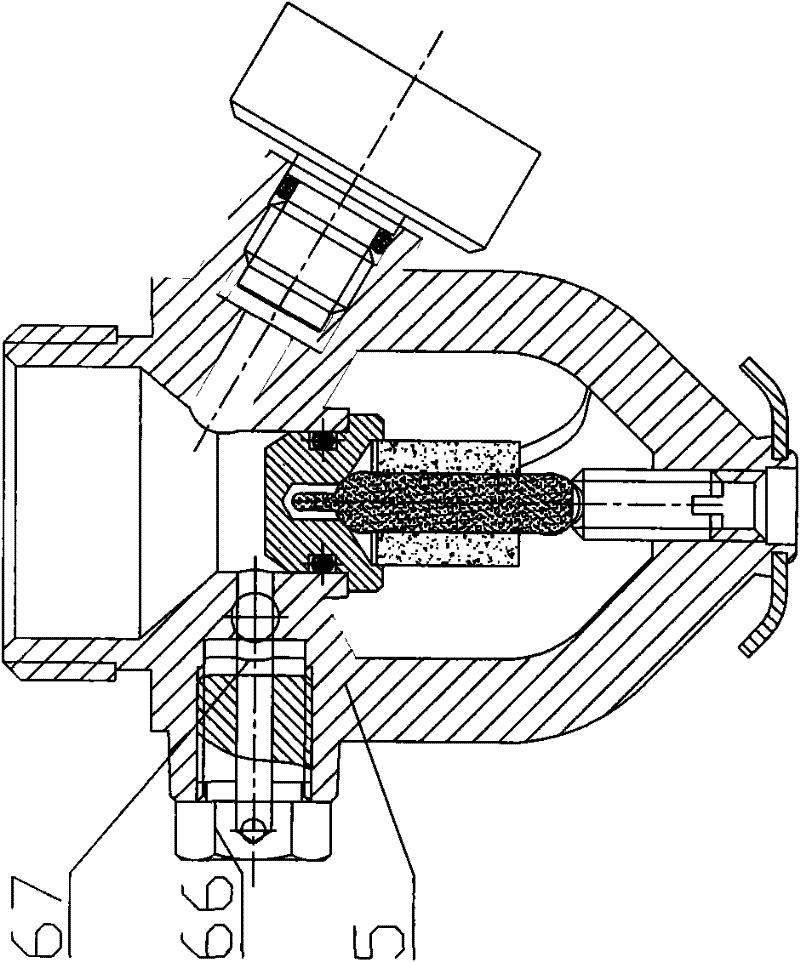

[0030] Such as figure 1 As shown, a suspended superfine dry powder fire extinguishing device, in the suspension state, the structure from top to bottom includes a suspension ring 1, a pressure signal switch 2, a fire extinguishing agent storage tank 3, a heat collecting cover 4, a nozzle 5 with a plug 7, a safety The pressure relief device 6, and the temperature-sensitive glass bulb 8 (or fusible element) supporting the plug 7, the automatic starting device 9, the set screw 10 for fixing the temperature-sensitive glass bulb or the fusible element. The fire extinguishing agent storage tank 3 is generally two hemispherical or ellipsoidal shapes that are stamped by steel plates and fastened together, and the middle seam is welded. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com