Water and sewage drainage facility for industrial recirculating aquaculture system

A technology of circulating water aquaculture and sewage discharge device, which is applied in fish farming, application, animal husbandry and other directions, can solve the problems of increasing system processing load and inconvenient operation, and achieves convenient production and application management, less floor space, and high sewage discharge efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific technical embodiments of the present invention are further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, rather than limit the rights of the present invention.

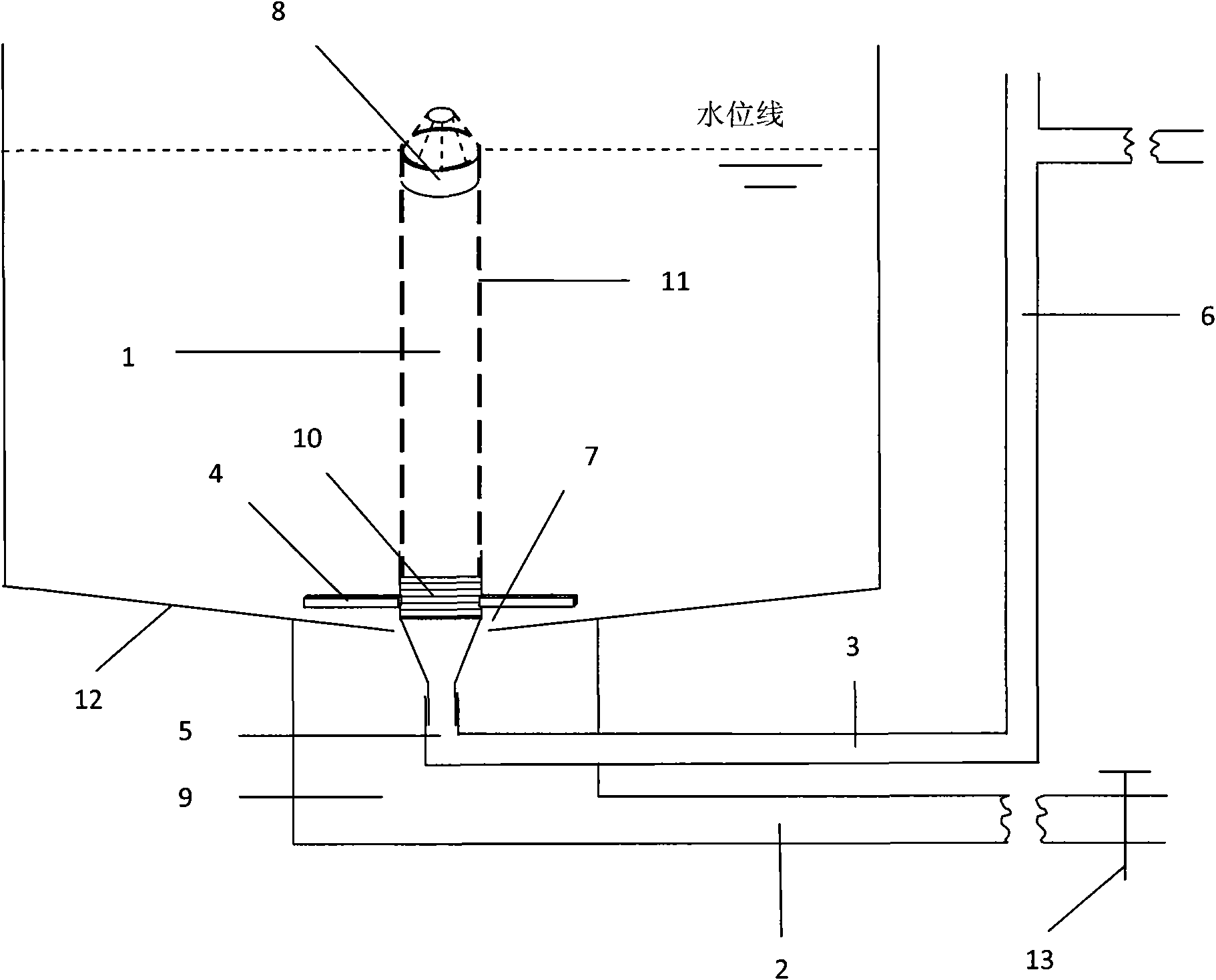

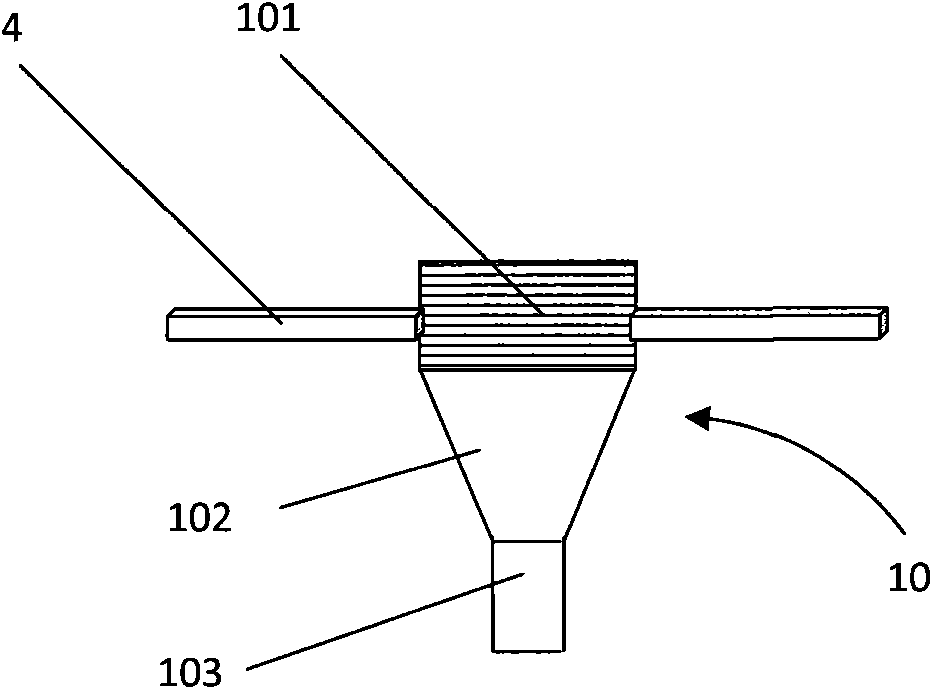

[0027] like figure 1 As shown in the figure, the drainage and sewage device of the industrialized circulating aquaculture system of the present invention comprises a central drainage pipe 1, a drainage pipe 2, a drainage pipe 3, a drainage hole clearance control panel 4, a supporting and fixed pipe 5 for the central drainage pipe of the culturing pond, Water level control pipe 6, sewage hole 7, filter cap 8, sewage tank 9 and socket-type joint pipe fitting 10, etc. The center drain pipe 1 of the breeding pond is placed in the breeding pond 12 of the recirculating aquaculture system. A series of small drainage holes 11 are drilled on the pipe wall of the center drain pipe 1 of the breeding pond. The lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com