Lens group

A lens set and lens technology, applied in the field of lens sets, can solve the problems of reducing the production accuracy and deviation of finished products, increasing the difficulty of demolding the first lens 21 and the second lens 22, etc., so as to reduce the difficulty of demolding, reduce the height, The effect of improving image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The lens set provided by the embodiment of the technical solution will be further described in detail below with reference to the drawings and embodiments.

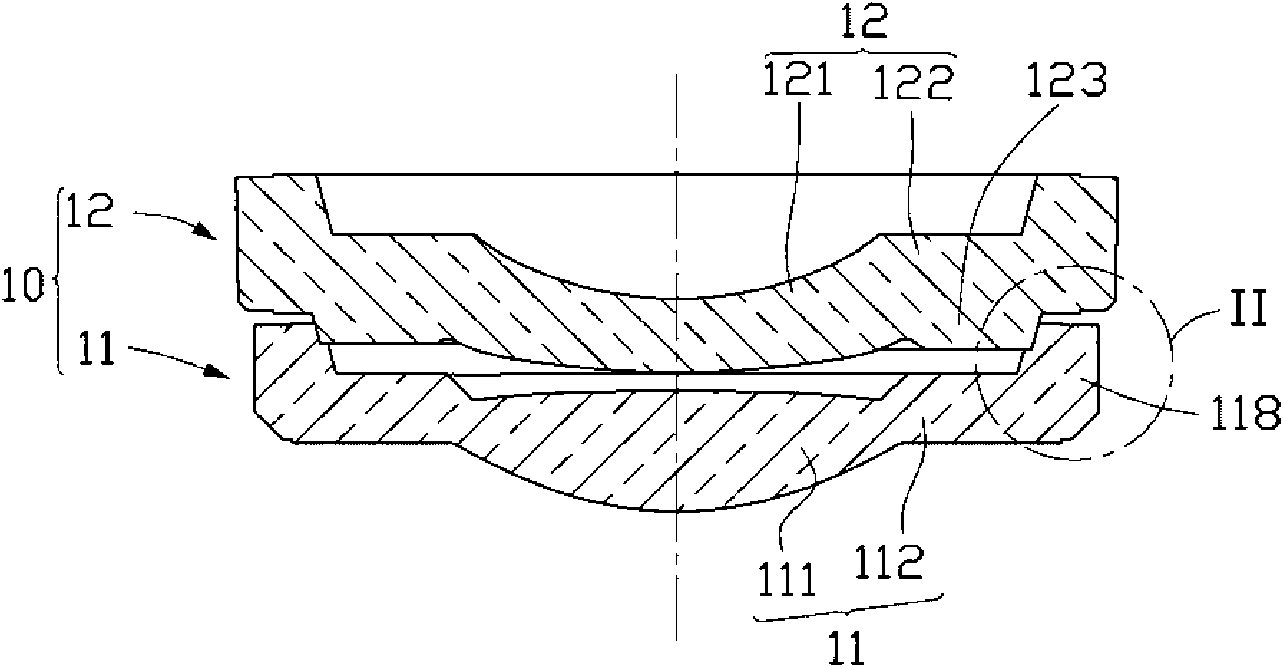

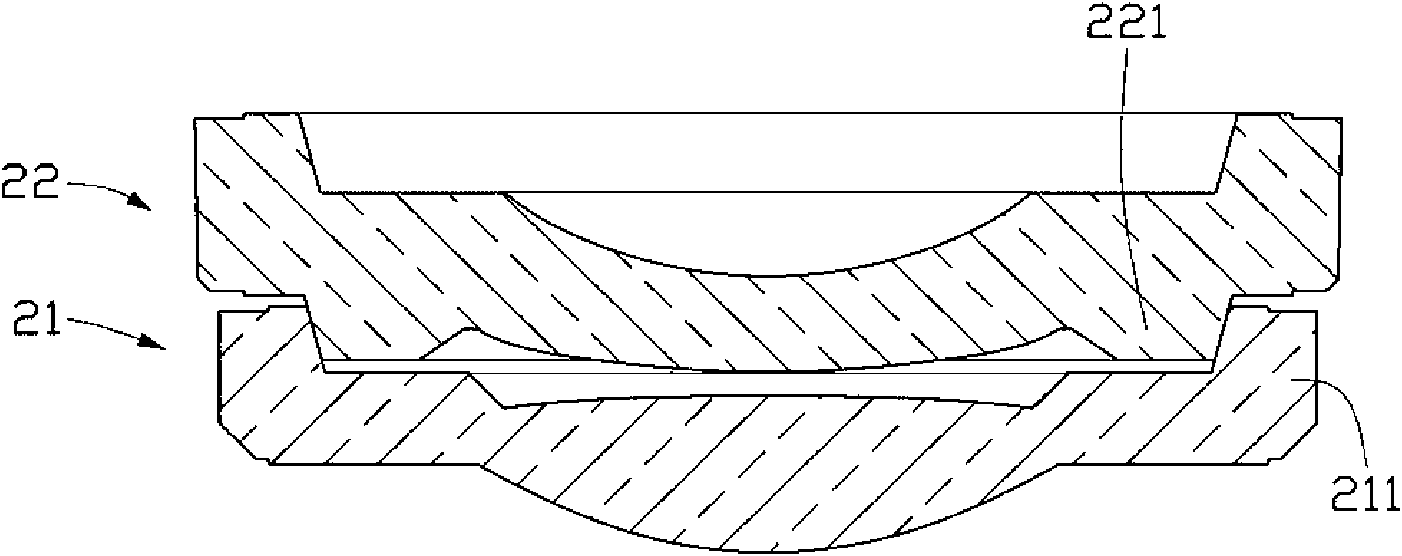

[0012] see figure 1 and figure 2 , the lens set 10 provided in this embodiment includes a first lens 11 and a second lens 12 assembled with the first lens 11 . Both the first lens 11 and the second lens 12 include an optical part located at the center of the lens and a fixing part located at the periphery of the lens for fixing the lens. The optical part is an effective optical imaging area, which is used to make the light beam pass through for imaging, while the fixing part is only used for fixing the lens and does not participate in the imaging.

[0013] In this embodiment, the first lens 11 includes a first optical portion 111 and a first fixing portion 112 . A step 118 protruding outward from the first fixing part 112 is disposed on the periphery of the first lens 11 (ie, the first fixing part 112 ). In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com