Magnet ring type settlement layered horizontal test system

A layered settlement and testing system technology, which is applied in the directions of height/level measurement, measuring device, surveying and navigation, etc., can solve problems such as inconsistent measurement positions, deflection of the settling tube 1, and decreased measurement accuracy, and achieve simple structure and high measurement accuracy. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

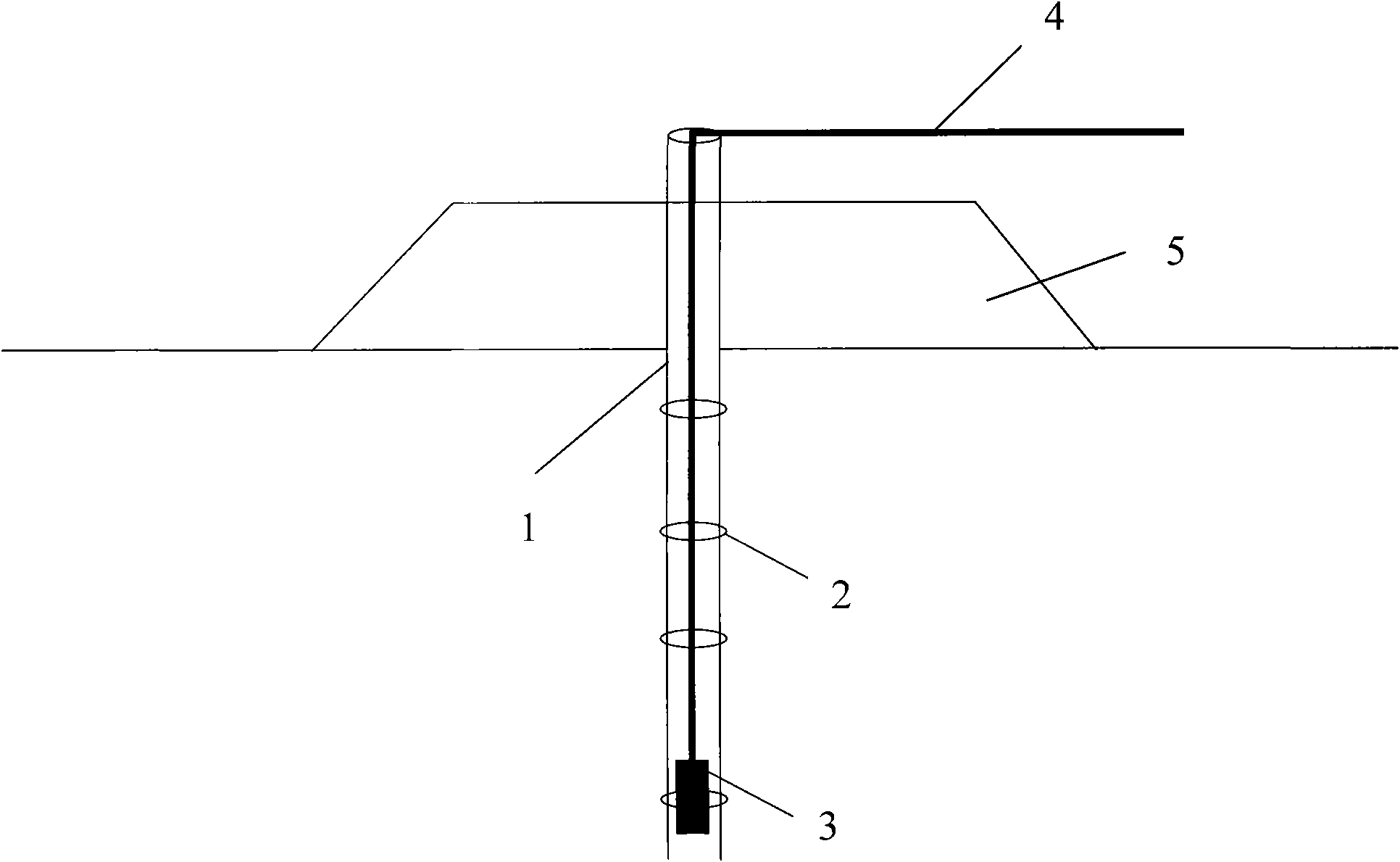

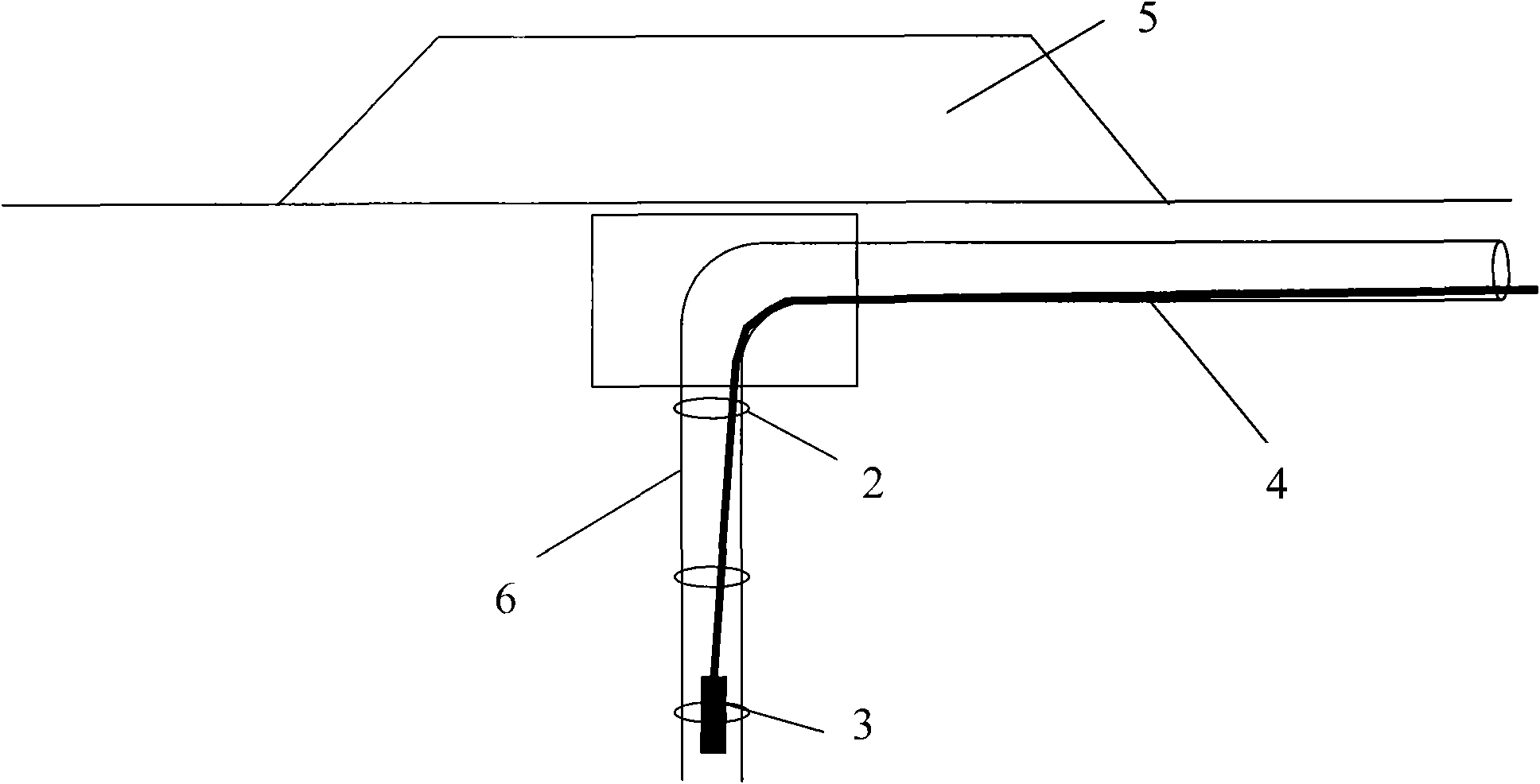

[0010] The magnetic ring type layered settlement level test system provided by the present invention will be described in detail below with reference to the drawings and specific embodiments. Components that are the same as those in the prior art use the same reference numerals, and detailed descriptions thereof are omitted.

[0011] Such as figure 2 As shown, the magnetic ring type layered settlement level test system provided by the present invention includes a settling tube 6 in an inverted L shape, a plurality of settling magnets installed on the outer circumferential surface of the lower part of the settling tube 6 at a distance from each other and built-in permanent magnets. Ring 2, the tester not shown in the figure, the probe 3 and the cable 4 connected between the probe 3 and the tester and have the function of a scale, and the upper end of the settling pipe 6 is located outside the slope foot of the roadbed 5 In the ground protection pool (not shown in the figure).

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com