Right-angled reflection type three-dimensional laser scanner and method for realizing three-dimensional imaging by using same

A three-dimensional laser and reflective technology, applied in optics, instruments, optical components, etc., can solve the problem that the work is easily disturbed by the outside world

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

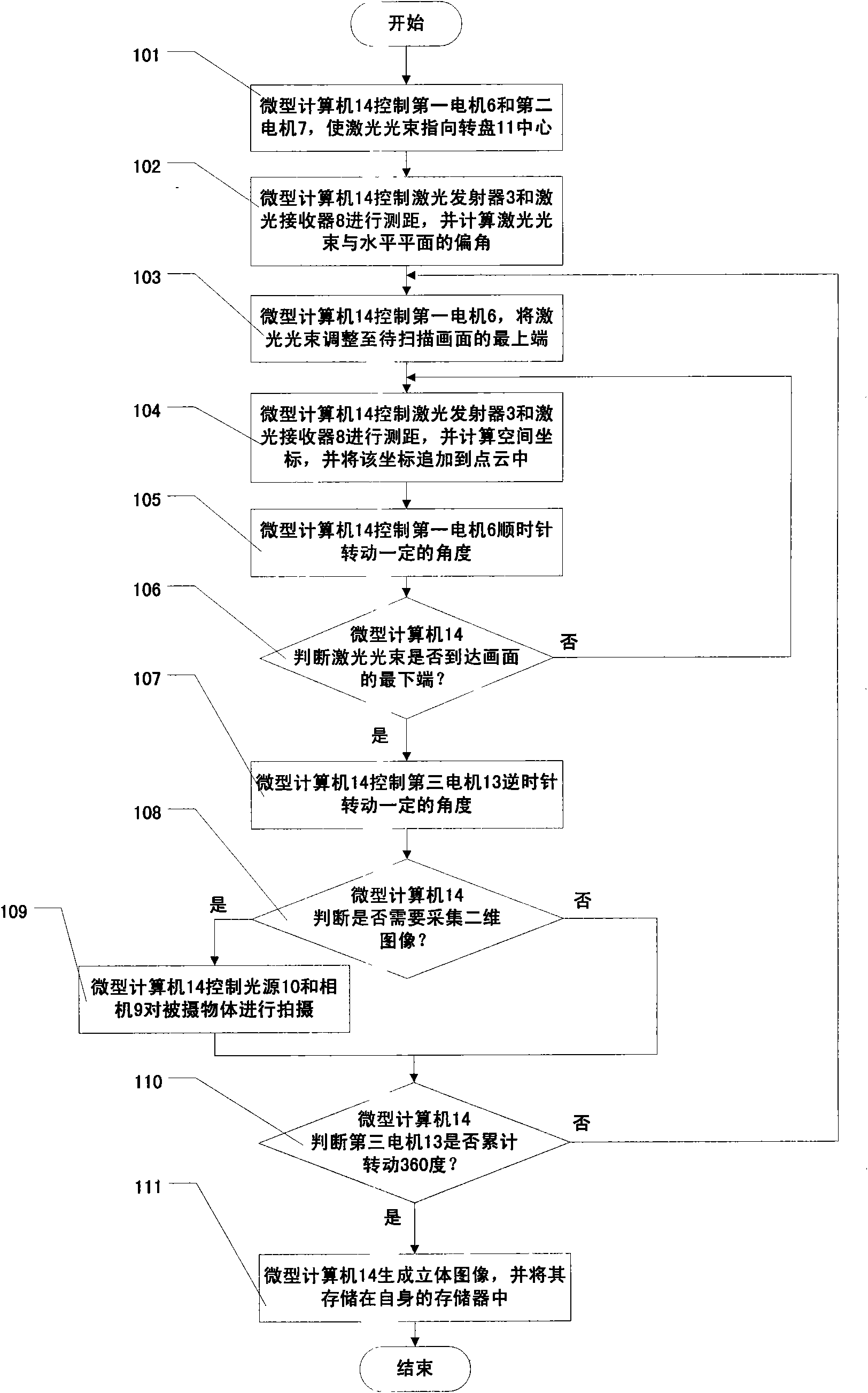

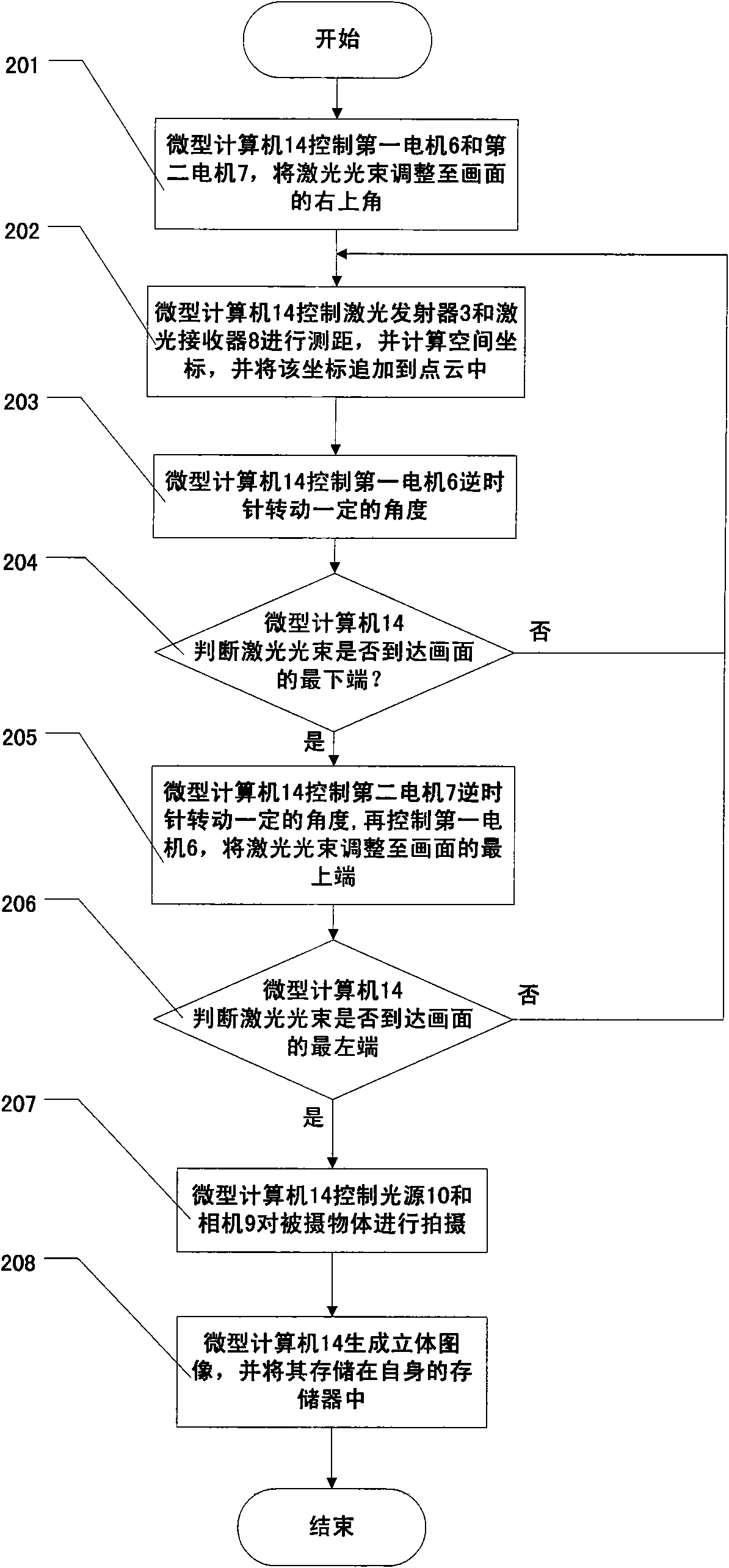

Embodiment 1

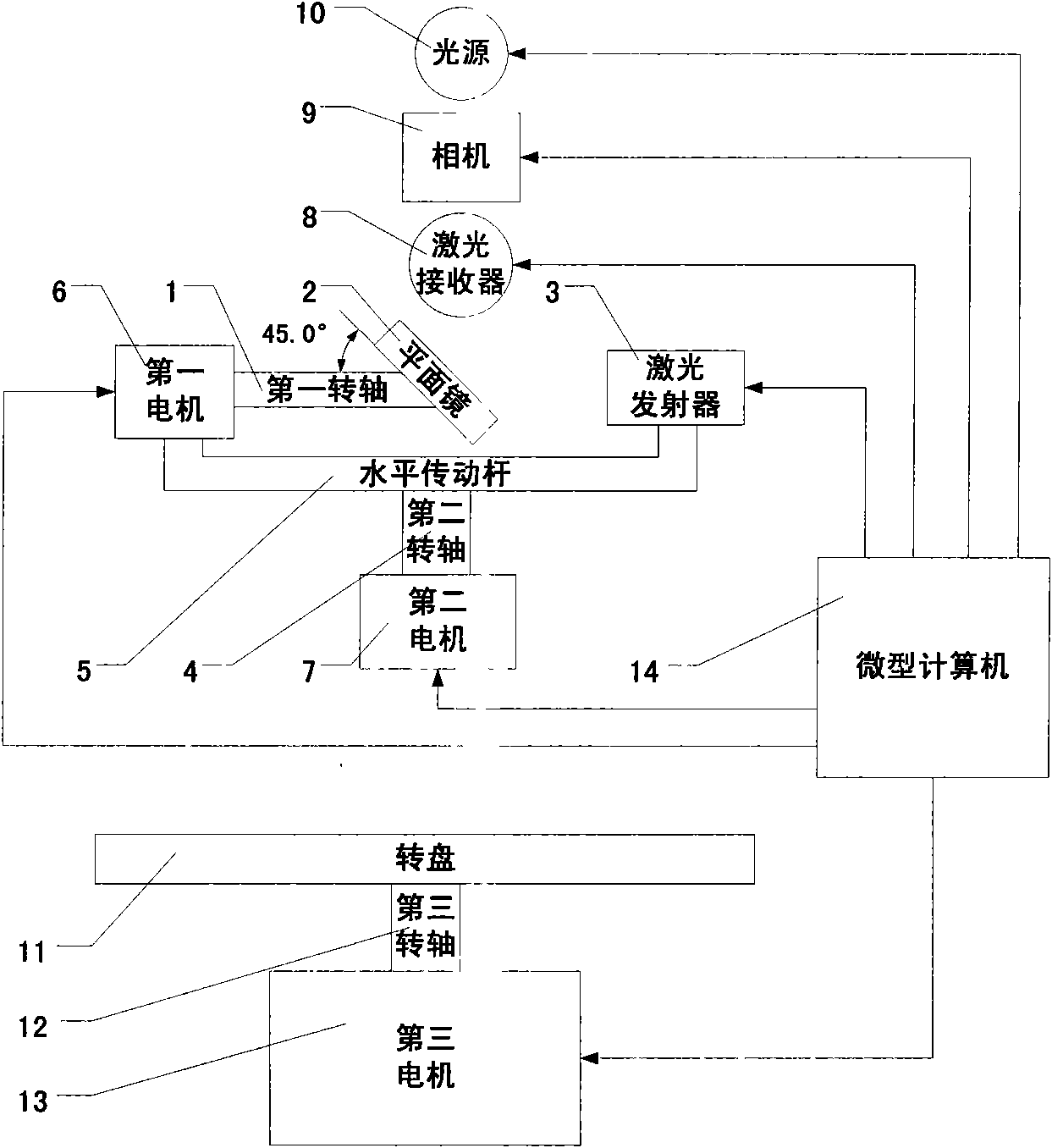

[0065] Example 1 as figure 1 As shown, a right-angle reflective three-dimensional laser scanner includes a three-dimensional laser scanning unit, a two-dimensional image capturing unit, a turntable and a microcomputer 14;

[0066] The three-dimensional laser scanning unit comprises a first rotating shaft 1, a second rotating shaft 4, a plane mirror 2, a horizontal transmission rod 5, a first motor 6, a second motor 7, a laser transmitter 3 and a laser receiver 8;

[0067] The second rotating shaft 4 controls the scanning of the laser on the horizontal plane, and the first rotating shaft 1 controls the scanning of the laser on the vertical plane; these two axes are perpendicular to each other; one end of the second rotating shaft 4 is connected with the second motor 7, and its The other end is connected with the horizontal transmission rod 5; the horizontal transmission rod 5 is connected with the first motor 6 and the laser transmitter 3 respectively; one end of the first rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com