Hose lamp with improved structure

A technology for improving the structure and hoses, which can be applied to the parts of lighting devices, the loss prevention measures of lighting devices, the semiconductor devices of light-emitting elements, etc. , the effect of high light utilization and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

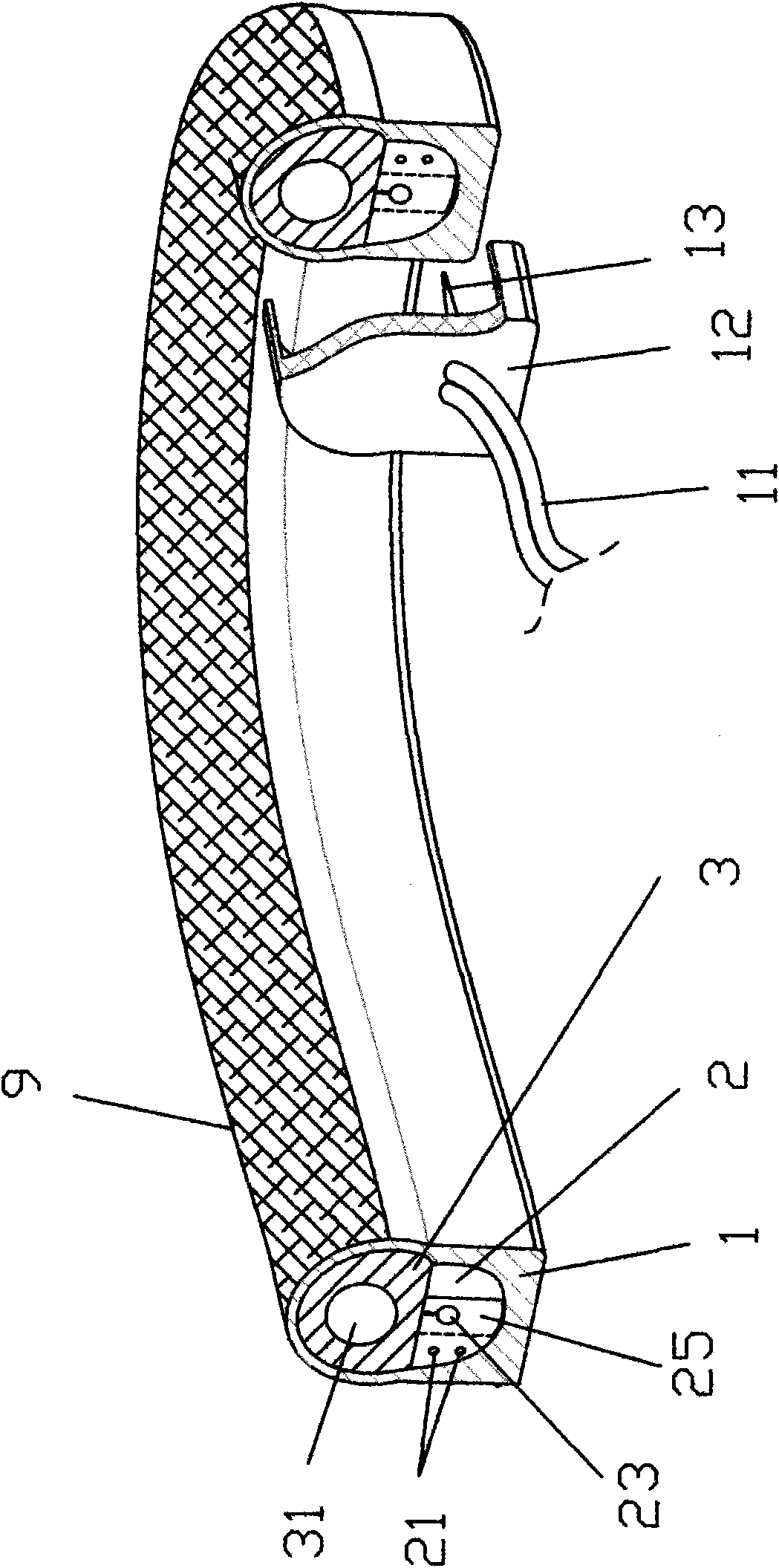

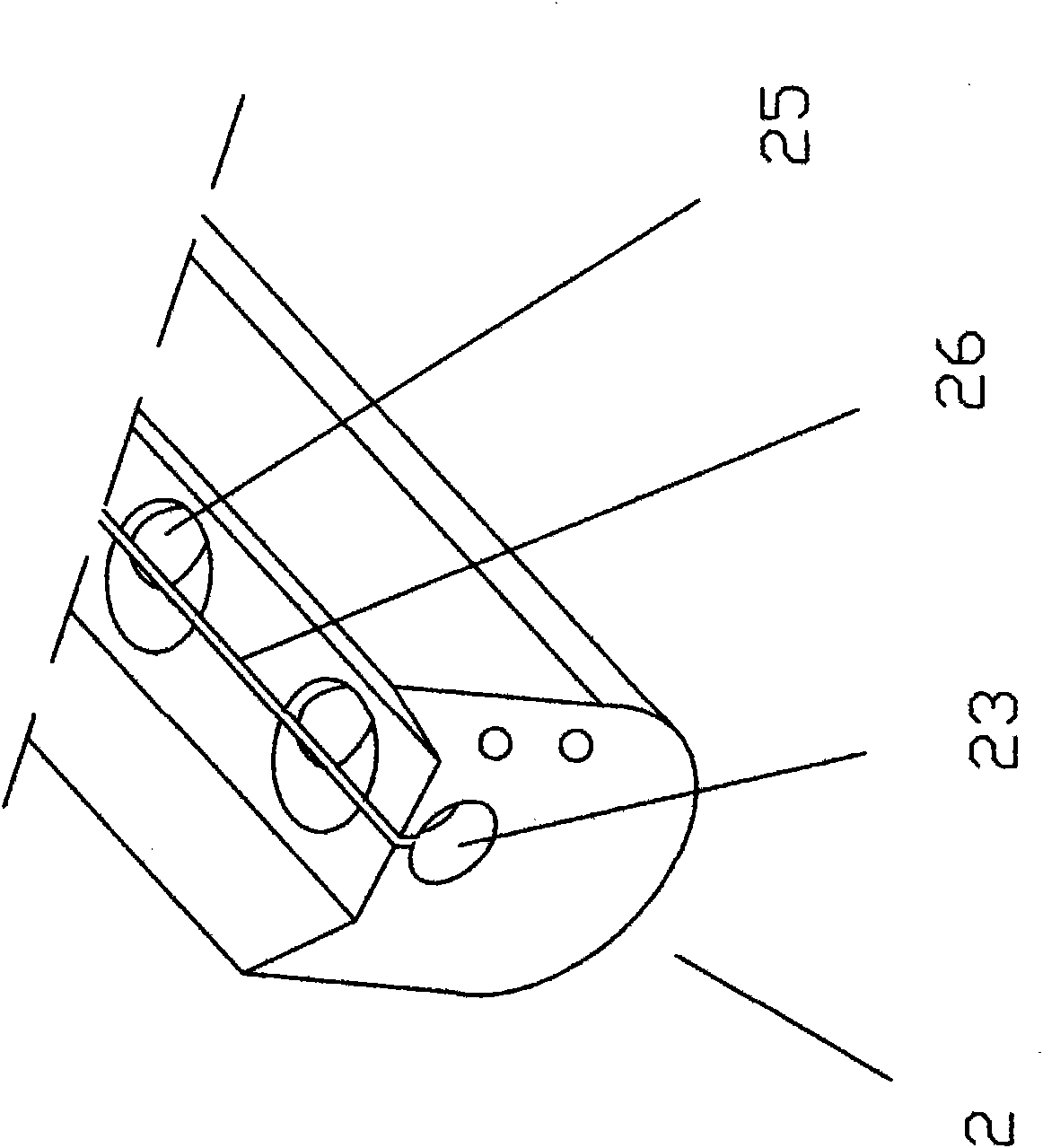

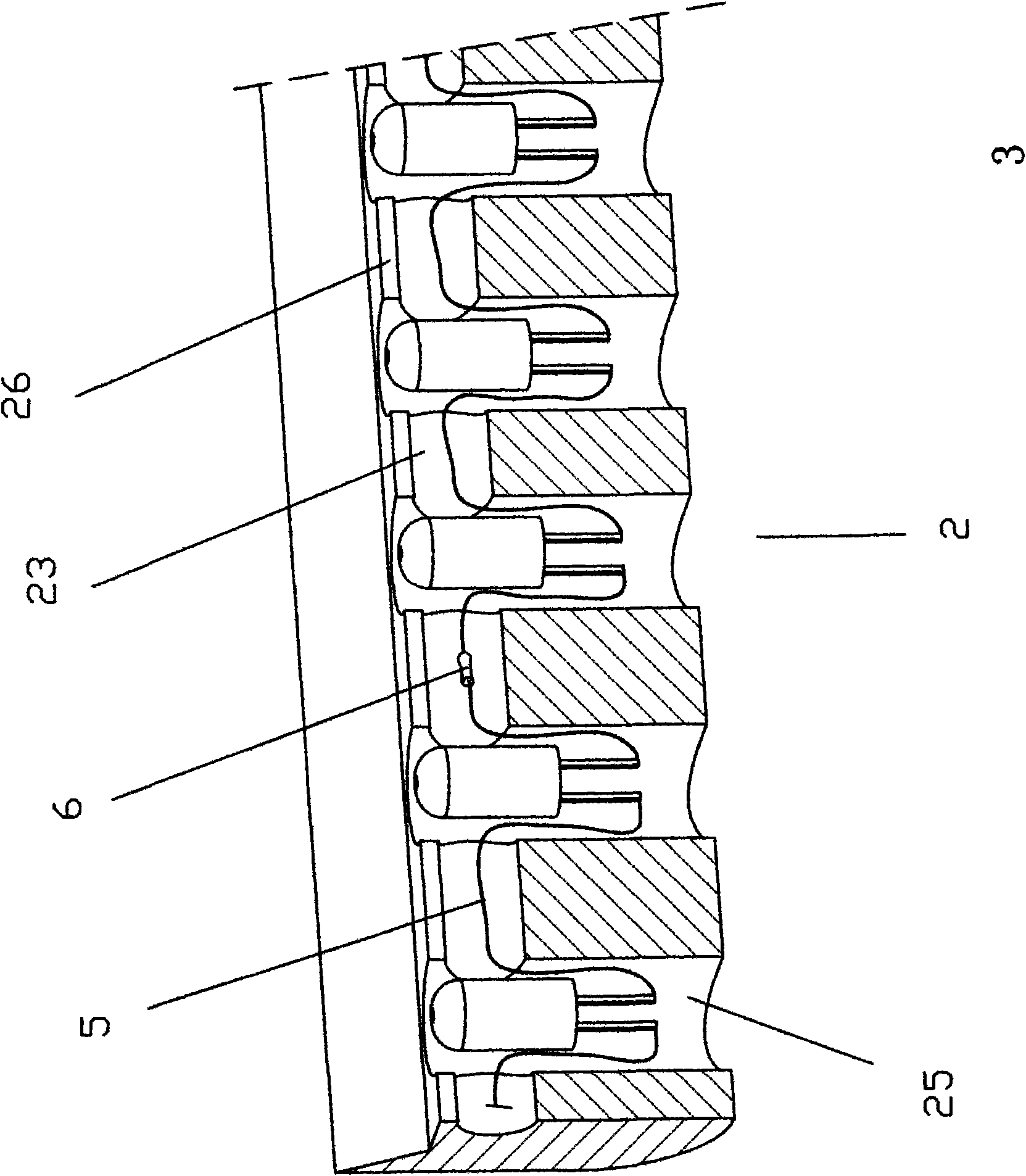

[0028] refer to figure 1 To Fig. 3, the present invention includes a flexible lamp body core wire 2, the core wire is an opaque flexible plastic material, and can also be a transparent plastic material, and the cross-sectional outer contour of the lamp body core wire is "U" shaped, so in The core wire of the lamp body has a good positioning effect when the fixed layer is set through the extruder, which avoids the disadvantage of using a square lamp body core wire in the prior art, which is prone to offset when the fixed layer is set through the extruder, resulting in defective products , the core wire can also be in other shapes such as "H" shape, the bottom of the structure core wire can play a role of positioning, and the top can play a role of concentrating and blocking light. A number of LED lamp body holes 25 with vertical core wires are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com