Light-duty automotive transmission with main box and secondary box

A technology of automobile transmission and main transmission, which is applied to components with teeth, belts/chains/gears, gear transmissions, etc., which can solve the problems of small number of gears, inconvenient operation, and difficulty in shifting gears, and achieve large carrying capacity , meet the development needs, and have strong adaptability to road conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

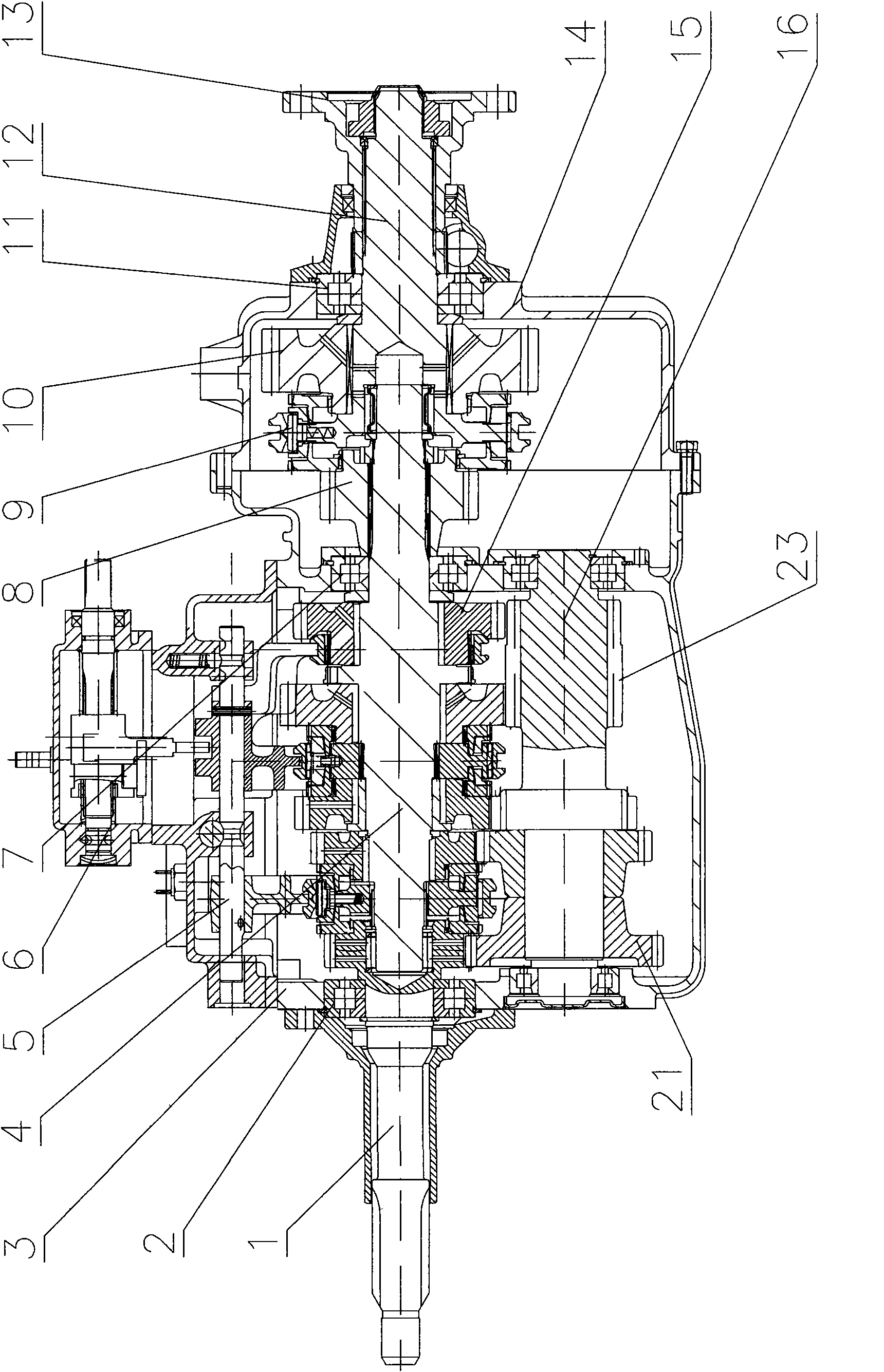

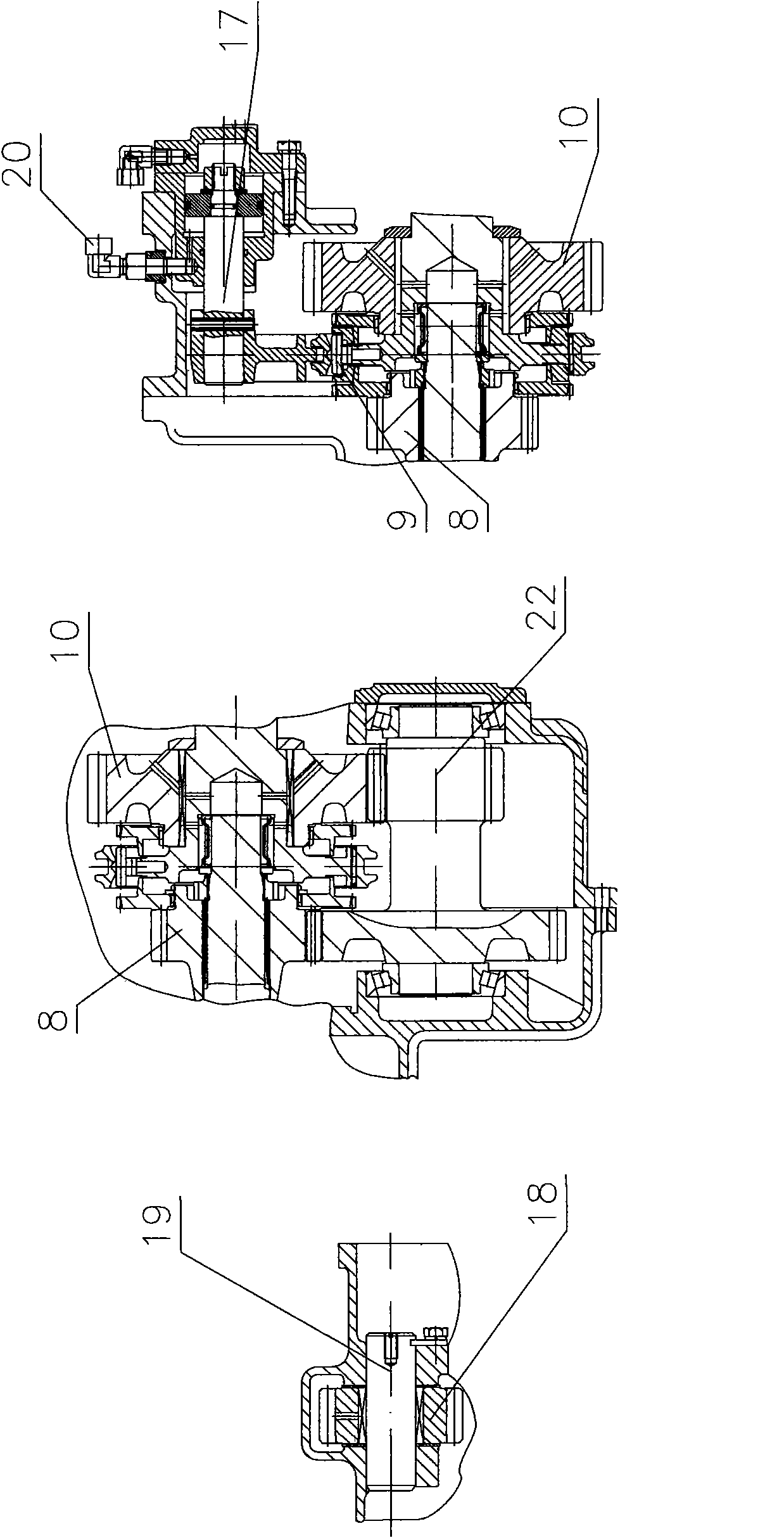

[0016] to combine figure 1 , figure 2 Shown, the present invention is a kind of light-duty automobile transmission with main and auxiliary case, comprises the casing 3 of main transmission, the rear casing 14 of the auxiliary transmission that is connected in casing 3 rear.

[0017] The first shaft 1 of the main transmission is supported on the housing 3 through a full cylindrical roller bearing 2 with a snap ring on the outer ring. One end of the second shaft 4 is supported on the inner hole of the first shaft 1 by a full roller bearing, and the other end is supported on the housing 3 by a cylindrical roller bearing 7 with a stop ring on the outer ring. Bearings are vacantly sleeved on the second shaft 4, and each shifting mechanism is fixed on the second shaft 4 by splines. The intermediate shaft 16 is supported on the housing 3 through cylindrical roller bearings. The first and second speed gears are integrated with the intermediate shaft 16. The gears mesh one by one. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com