Fixing method with self-lock nut supporting plate and rivet free supporting plate self-lock nut

A technology of self-locking nuts and fixing methods, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of not being able to install on arc surfaces, increasing installation difficulty, and time-consuming and laborious installation, so as to improve fatigue life, The effect of long service life and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

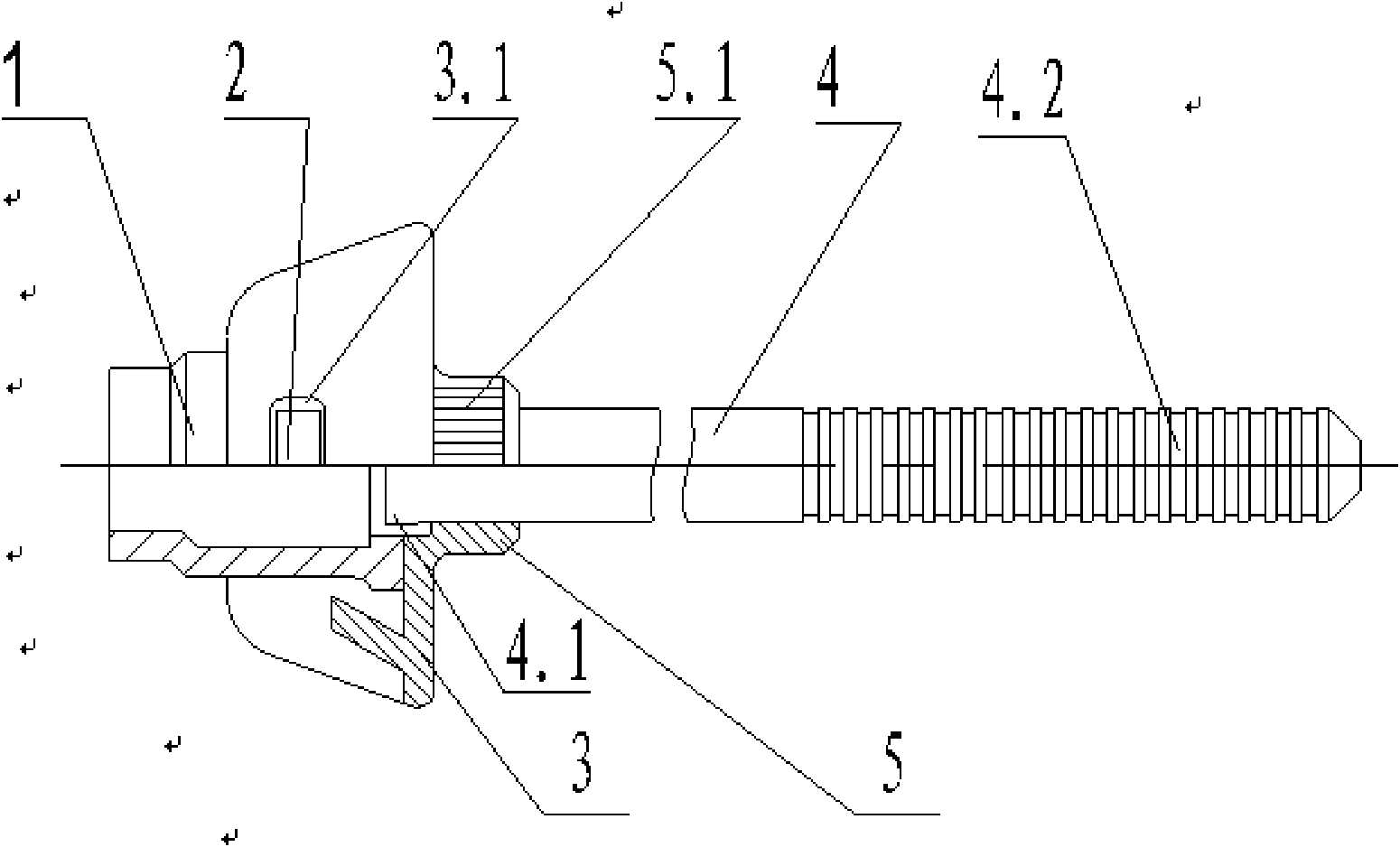

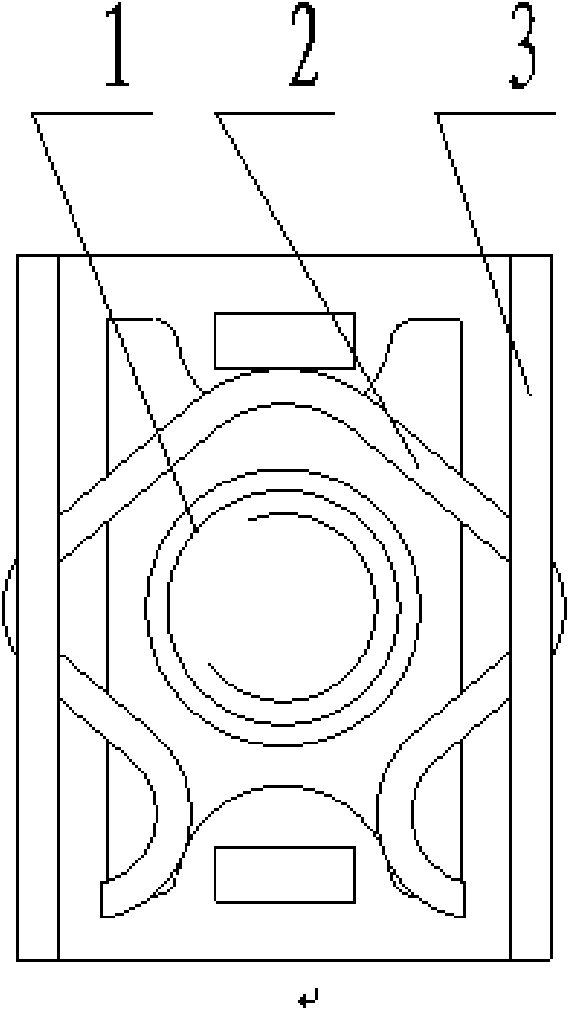

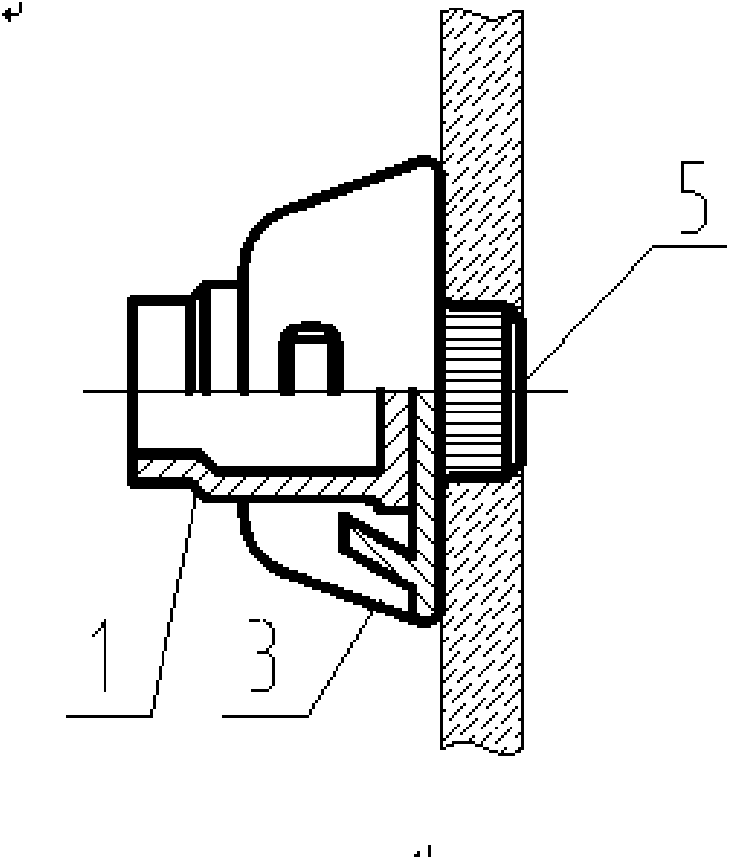

[0015] Embodiment of the present invention: when fixing the supporting plate with the self-locking nut on the structural parts that need to be connected, a fixing method of the supporting plate with the self-locking nut of the present invention is adopted for implementation, that is, the supporting plate with the self-locking nut is first fixed on the supporting plate. Make a boss protruding from the bottom surface of the pallet and have a through hole on the board, then pass a pull rod through the through hole of the boss of the pallet, and make a section of tapered cylinder at one end of the rod, so that the The diameter of the tapered cylinder is larger than the diameter of the through hole of the boss of the supporting plate, and then the boss of the supporting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com