Heat insulating and supplying building material component taking glass vacuum tube as heat insulating layer of heat insulation diffuser

A glass vacuum tube and light-transmitting cover technology, applied in building components, building materials, buildings, etc., can solve the problems of inability to supply heat, lighting, air exchange, affecting indoor environment, poor thermal insulation performance, etc., and achieve good thermal insulation performance and cost. Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

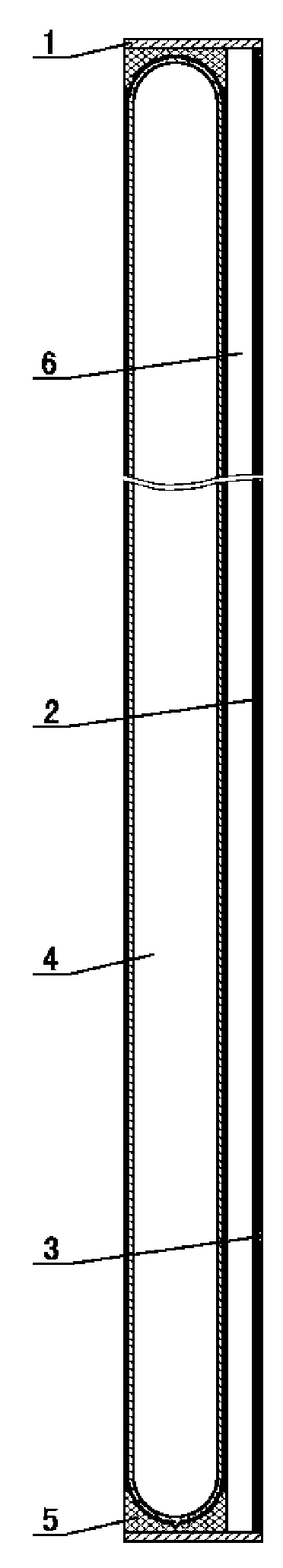

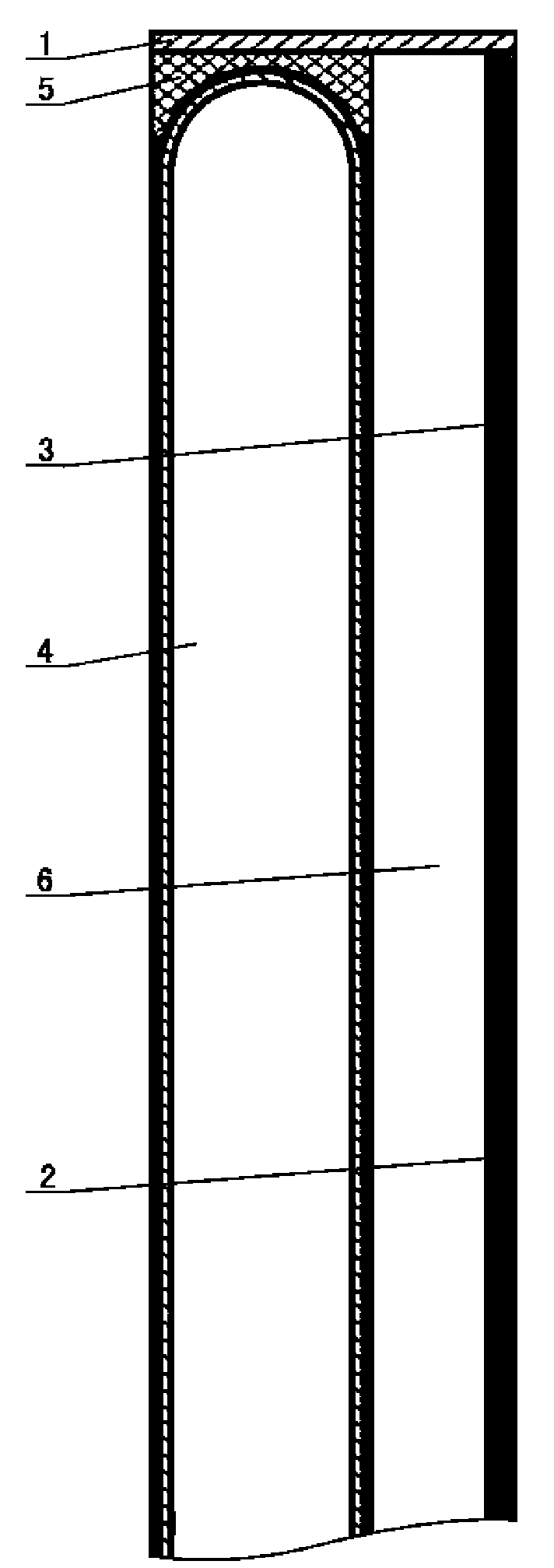

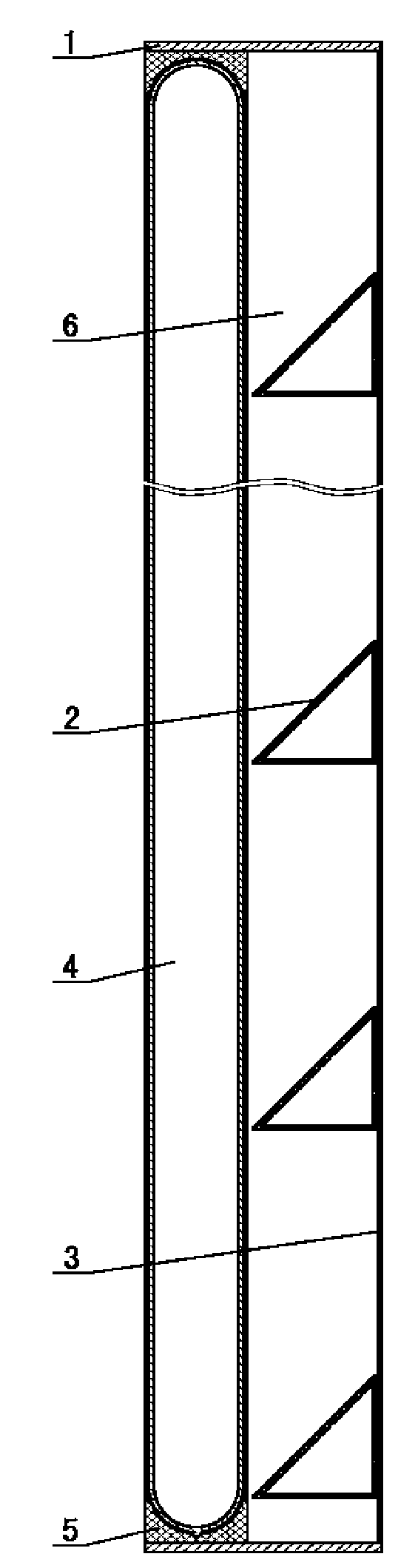

[0023] Such as figure 1 , 2 As shown: the insulation layer of the heat preservation translucent cover is the heat preservation and heating building material assembly of the glass vacuum tube 4, which is made of the vacuum glass tube 4 positioned through the heat preservation positioning sheath 5, the sealant 8 glued, and the isolation support element 1 framed and connected to form a heat preservation transparent The photomask and the heat collecting element 2 are compositely connected to the back plate 3 of the heat collecting element as a heat collecting film layer. The heat preservation translucent cover is formed by the vacuum glass tube 4 being positioned through the heat preservation positioning sheath 5, the sealant 8 glued, and the isolation support element 1 framed and connected. Between the light-transmitting cover and the heat-collecting element backboard 3 is a hollow heat-insulating interlayer 6. The heat-insulation layer of the heat-insulating light-transmitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com