Thickening synergist composition for efficient pesticide avermectin oil

A technology of abamectin emulsifiable concentrate and viscosity-increasing synergist, which is applied in the direction of chemicals, applications, and biocides for biological control, and can solve problems such as unobvious viscosity of liquid medicine, unqualified emulsification performance, and reduced effect , to achieve the effect of reducing droplet drift, improving direct effect and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the synthesis of castor oil polyoxyethylene ether sulfonate ammonium salt

[0018] In 100 liters of stainless steel reactors with agitator, thermometer, condenser, solvent recovery tank, add 50 kilograms of castor oil polyoxyethylene ethers (n=35, produced by Jiangsu Zhongshan Chemical Co., Ltd., commonly known as BY-125), Start stirring, raise the temperature to 40°C, add 5 kg of sulfamic acid and 1.6 kg of urea in batches within 0.5 hours, raise the temperature to 90-110°C for 2 hours after adding, cool down to 60°C, add methanol and filter to remove sulfamic acid and urea , the filtrate is steamed out of methanol to obtain the raw material castor oil ammonium polyoxyethylene ether sulfonate of the present invention, and the product is designated as B-1.

Embodiment 2

[0019] The synthesis of embodiment 2 castor oil polyoxyethylene ether sulfonate ammonium

[0020] In 100 liters of stainless steel reactors with agitator, thermometer, condenser, solvent recovery tank, add 10 kilograms of castor oil polyoxyethylene ethers (n=90, produced by Jiangsu Zhongshan Chemical Co., Ltd., commonly known as BY-140), 20 kg BY-125 and 30 kg castor oil, start stirring, heat up to 40°C, add 12.7 kg of sulfamic acid and 4.1 kg of urea in batches within 0.5 hours, heat up to 90-110°C for 2 hours, cool down to 60°C ℃, add methanol and filter to remove sulfamic acid and urea, and the filtrate steams methanol to obtain the intermediate castor oil ammonium polyoxyethylene ether sulfonate of the present invention, and the product is designated as B-2;

Embodiment 3

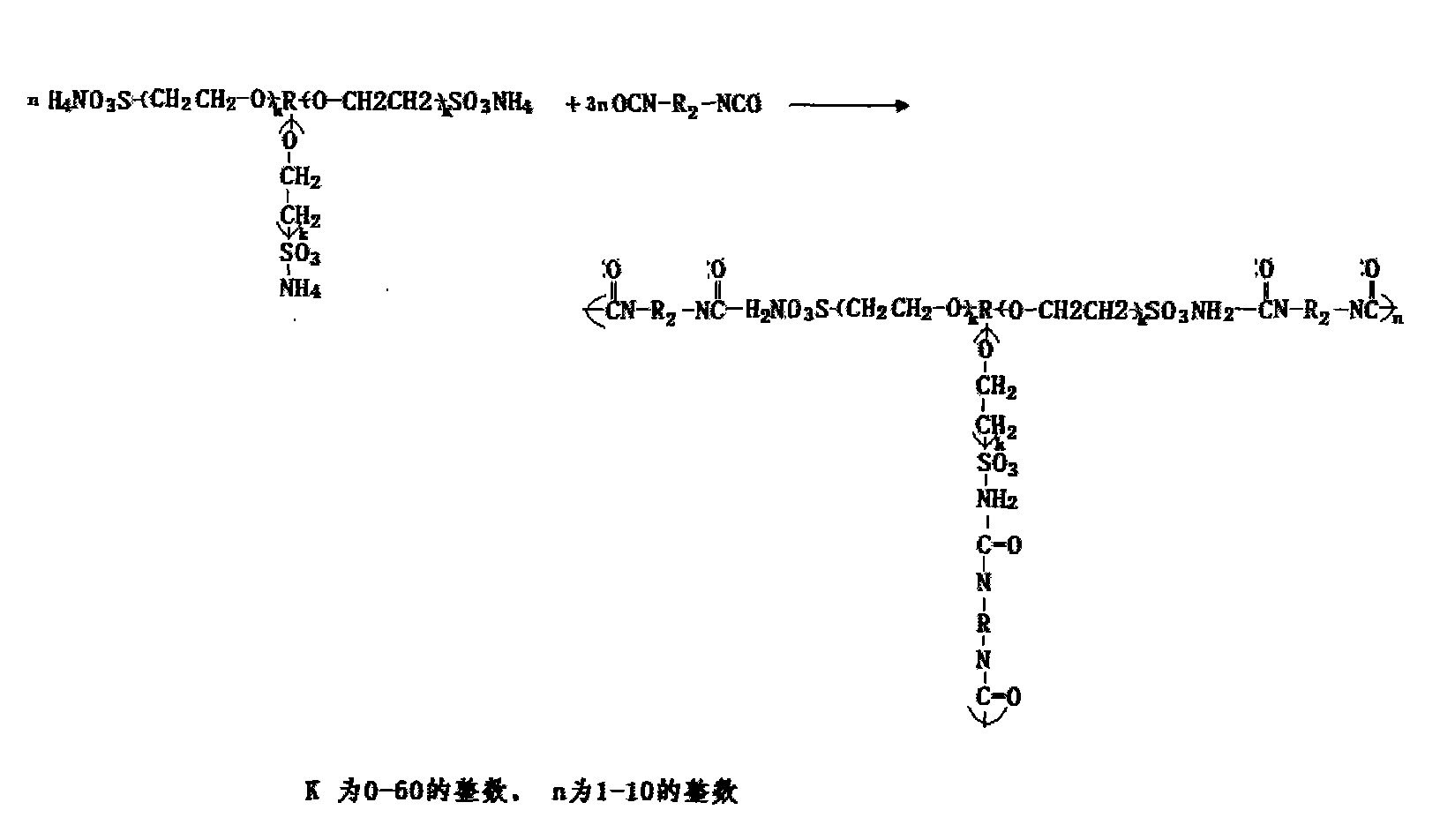

[0021] The synthesis of embodiment 3 castor oil polyoxyethylene ether sulfonate ammonium isocyanate polymer

[0022] In a 50-liter stainless steel reaction kettle with a stirrer and a thermometer, add 30 kg of B-1, start stirring, heat up to 80°C, and start to continuously add 4.5 kg of PAPI (Yantai Wanhua Polyurethane Co., Ltd. produced by the company), the temperature is maintained at 100-120° C., kept for 2 hours, and cooled to 60° C. to obtain the intermediate castor oil polyoxyethylene ether sulfonate ammonium isocyanate polymer of the present invention, and the product is designated as B-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com