Tobacco breeding program controlling and dishing seeder

A seeding machine and traying technology, which is applied to sowing, seed treatment methods, cultivation, etc., can solve the problems of impact on survival rate and low germination efficiency, and achieve the effect of saving coated seeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

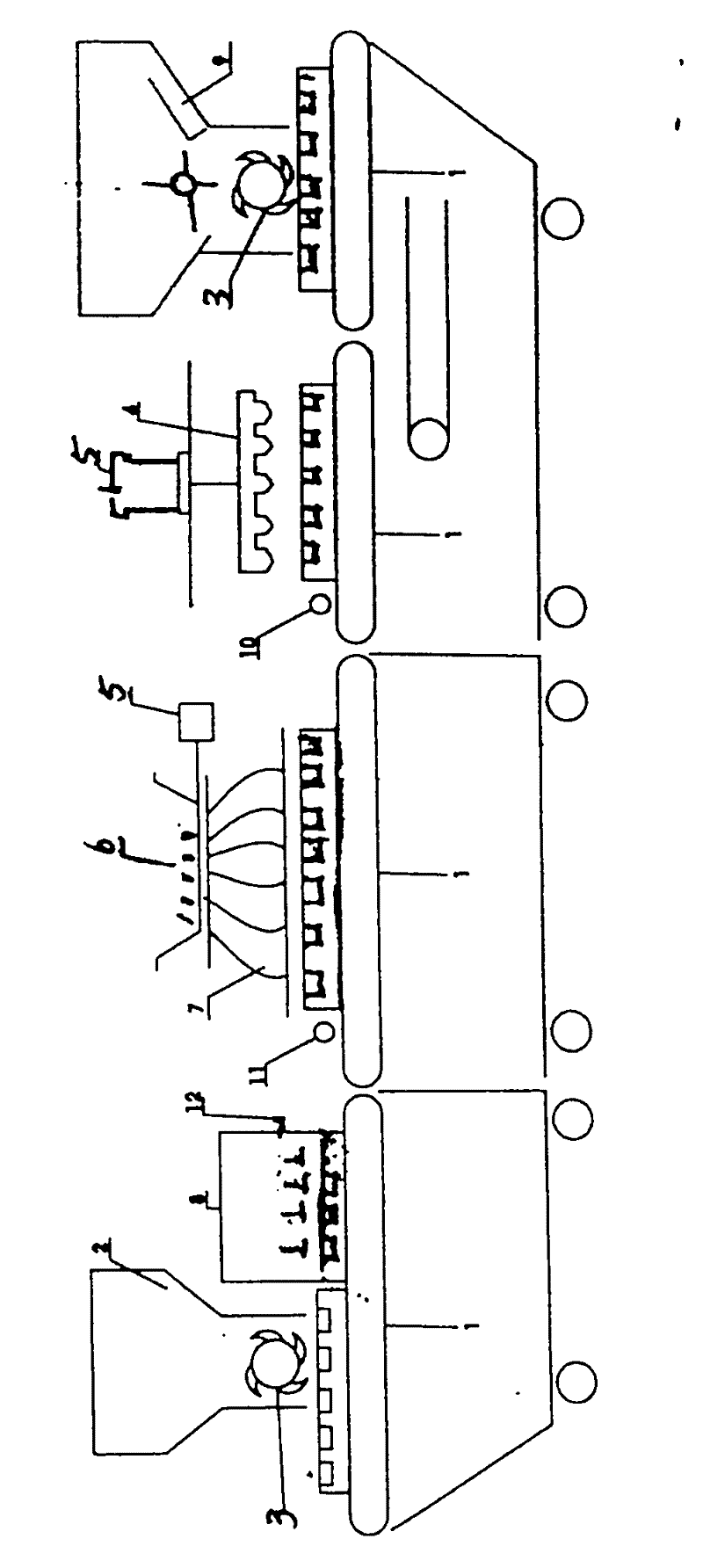

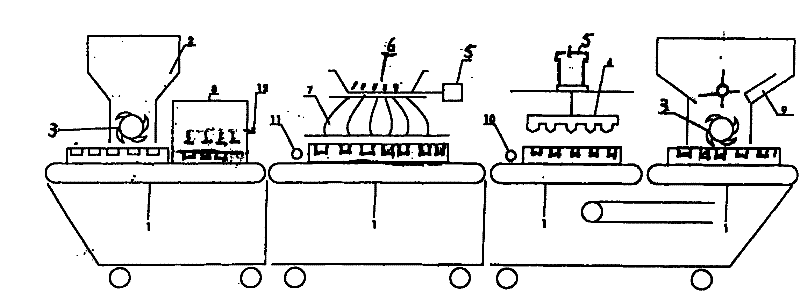

[0014] Such as figure 1 Shown: a tobacco breeding program control tray seeder, which is composed of five parts: a base loading part, a hole pressing part, a seeding part, a cracking part, and a base compounding part. A conveyer belt 1 is arranged below the sowing part, the cracking part and the compound base part; the base loading part fills the nutrient substrate on the conveyer belt 1 with a substrate, and the nutrient substrate is transmitted to the pressure hole part by the conveyer belt 1; The pressure hole part presses the matrix of the nutrition base plate, and the nutrition base plate is transported to the sowing part through the conveyor belt 1; The nutrient base plate is transported to the cracking part; the cracking part sprays water to the sown nutrient base plate, and the nutrient base plate is transported to the rebase part through the conveyor belt 1; the rebase part sprinkles the matrix on the nutrient base plate, The nutrient base plate is output through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com