Synchronizing ring of a synchronizing device

A technology of synchronous device and synchronous ring, which is applied in the field of synchronous ring, can solve problems such as synchronous ring failure, and achieve the effect of low-cost manufacturing, high load capacity, and no need for post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

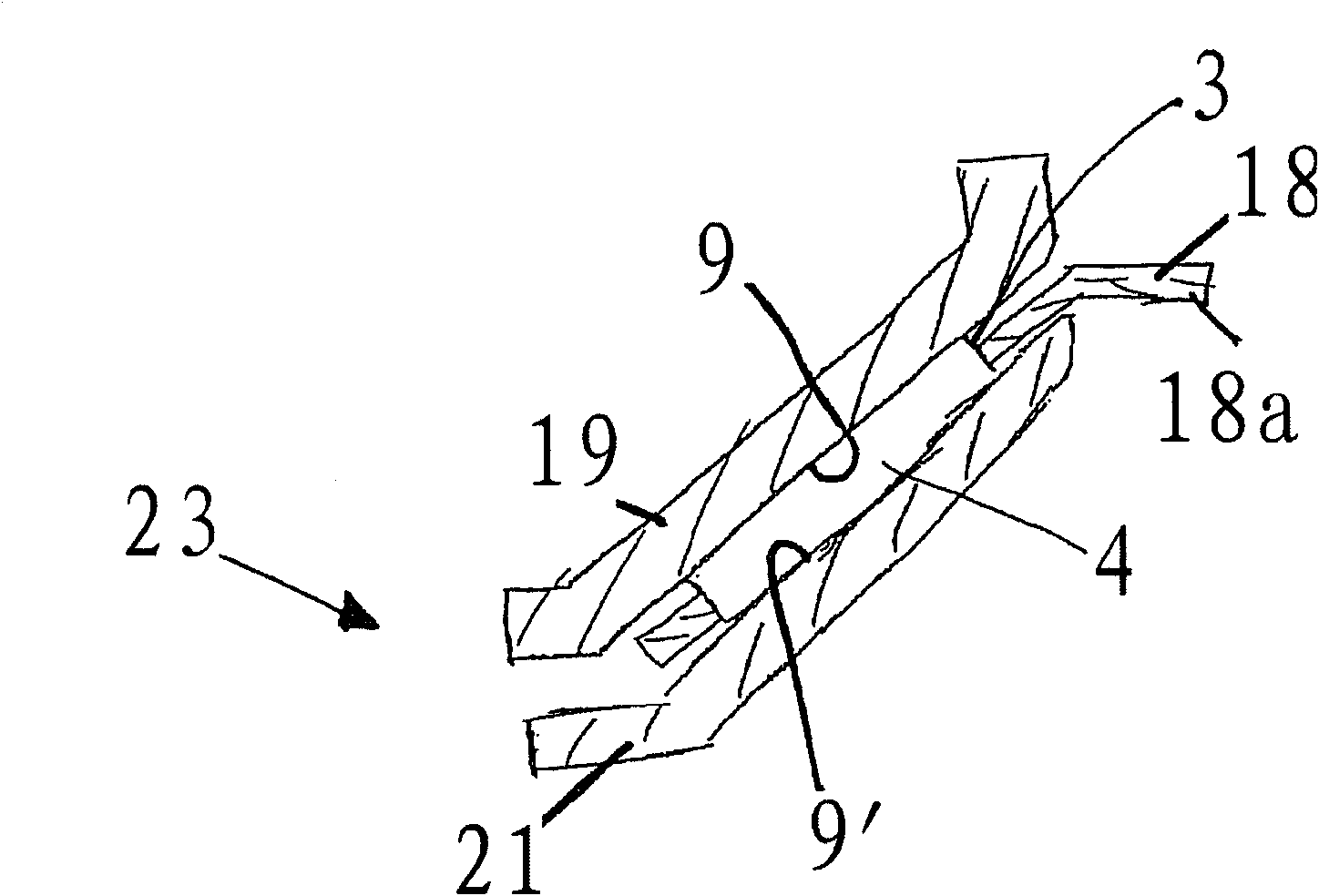

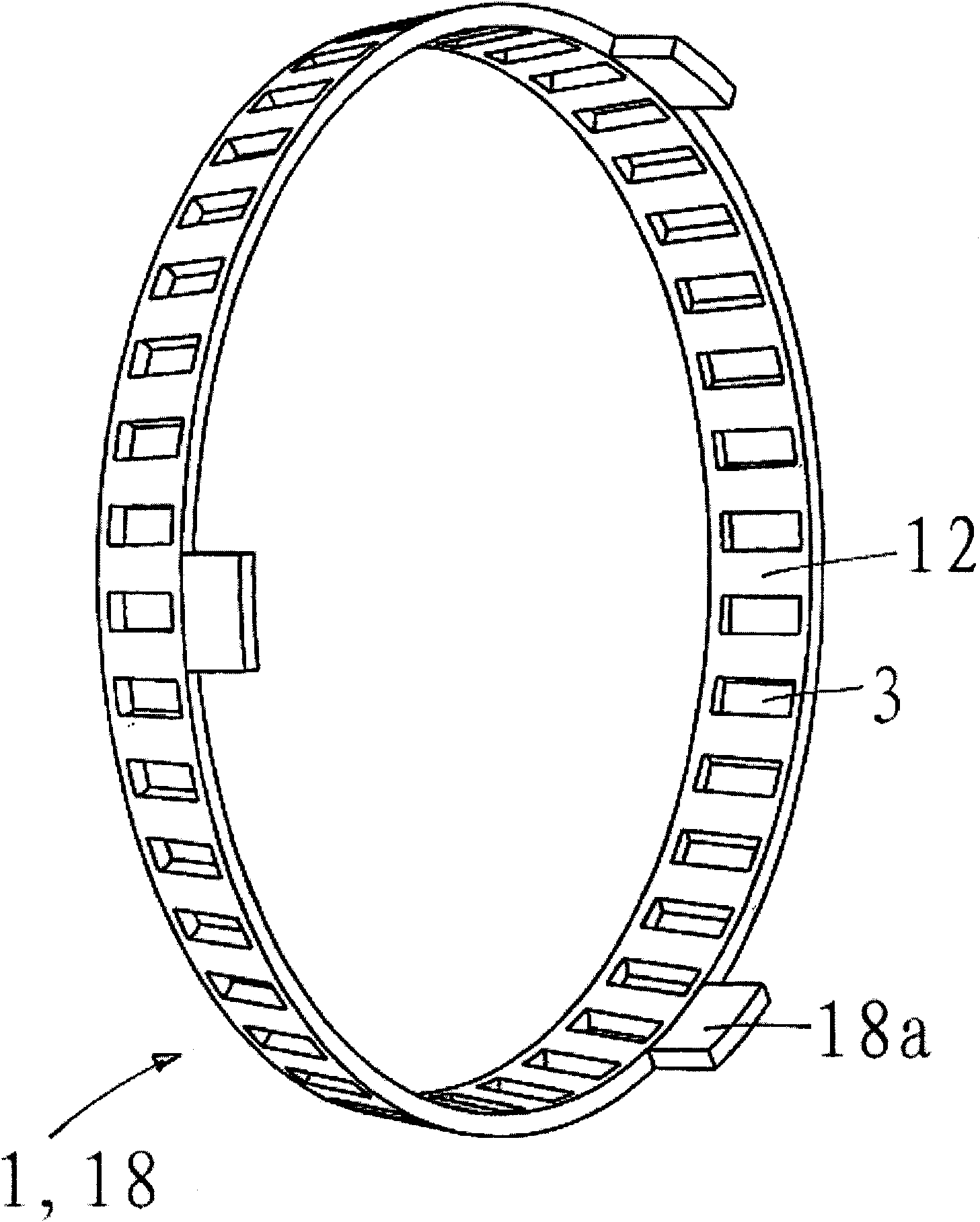

[0026] figure 1 By way of example, a synchronizing device with an outer synchronizing ring 19 , a central synchronizing ring 18 and an inner synchronizing ring 21 is shown. The synchronizing body 13 is fastened with internal toothing for a non-rotatable arrangement on the drive shaft. A driven wheel 16 is arranged next to the synchronizing body 13 . The clutch main body 17 is connected with the driven wheel 16, and the synchronous projection 18a of the intermediate ring 18 is embedded in the recess 17a of the clutch main body. The intermediate ring 18 forms a first friction pair 20 with the mating friction surface 9 of the outer synchronizing ring 19 as mating cone 8, and forms a second friction pair 22 with the mating friction surface 9' of the inner synchronizing ring 21. The mating friction surfaces 9 and 9' are not post-treated. The connection of the driven wheel 16 and the synchronizing body 13 is realized through a sliding sleeve 14 .

[0027] The inner edge 21 a of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com