Double-clutch automatic speed changer

An automatic transmission and dual-clutch technology, which is applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problems of complex structure of combined dual-clutch, large volume and weight of the transmission, and large increase in radial dimension , to achieve the effect of simple and reasonable structure, improving economical use and reducing radial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

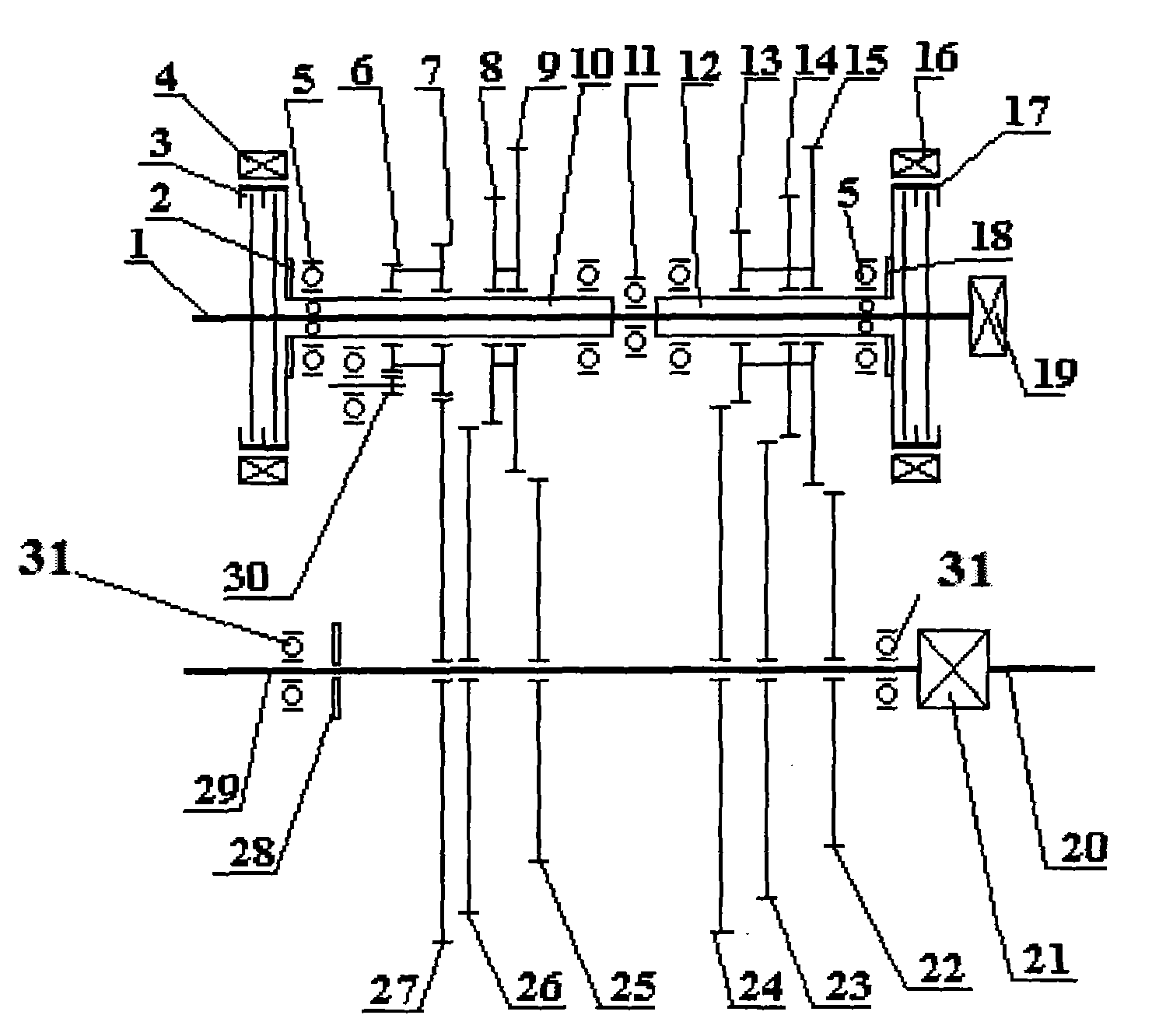

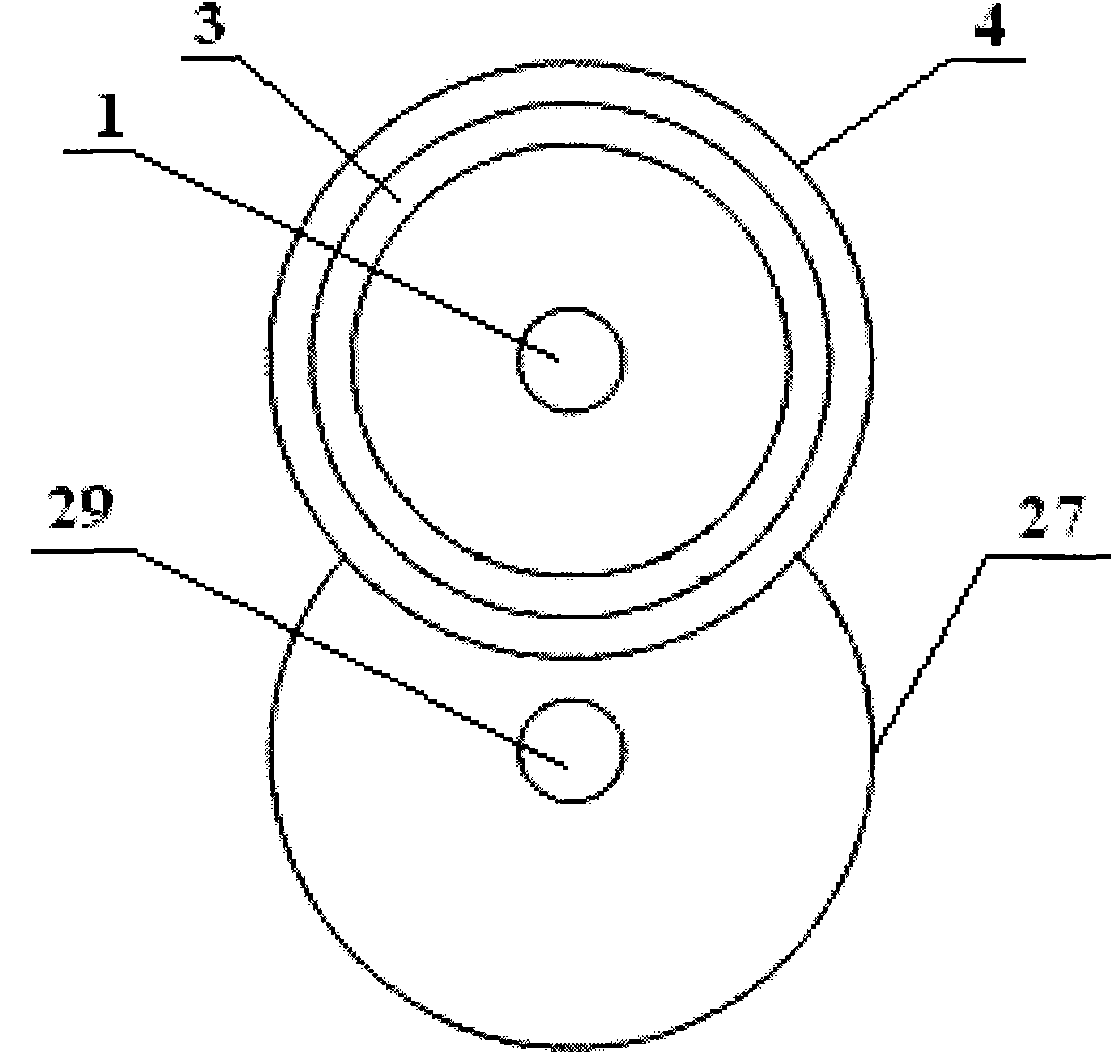

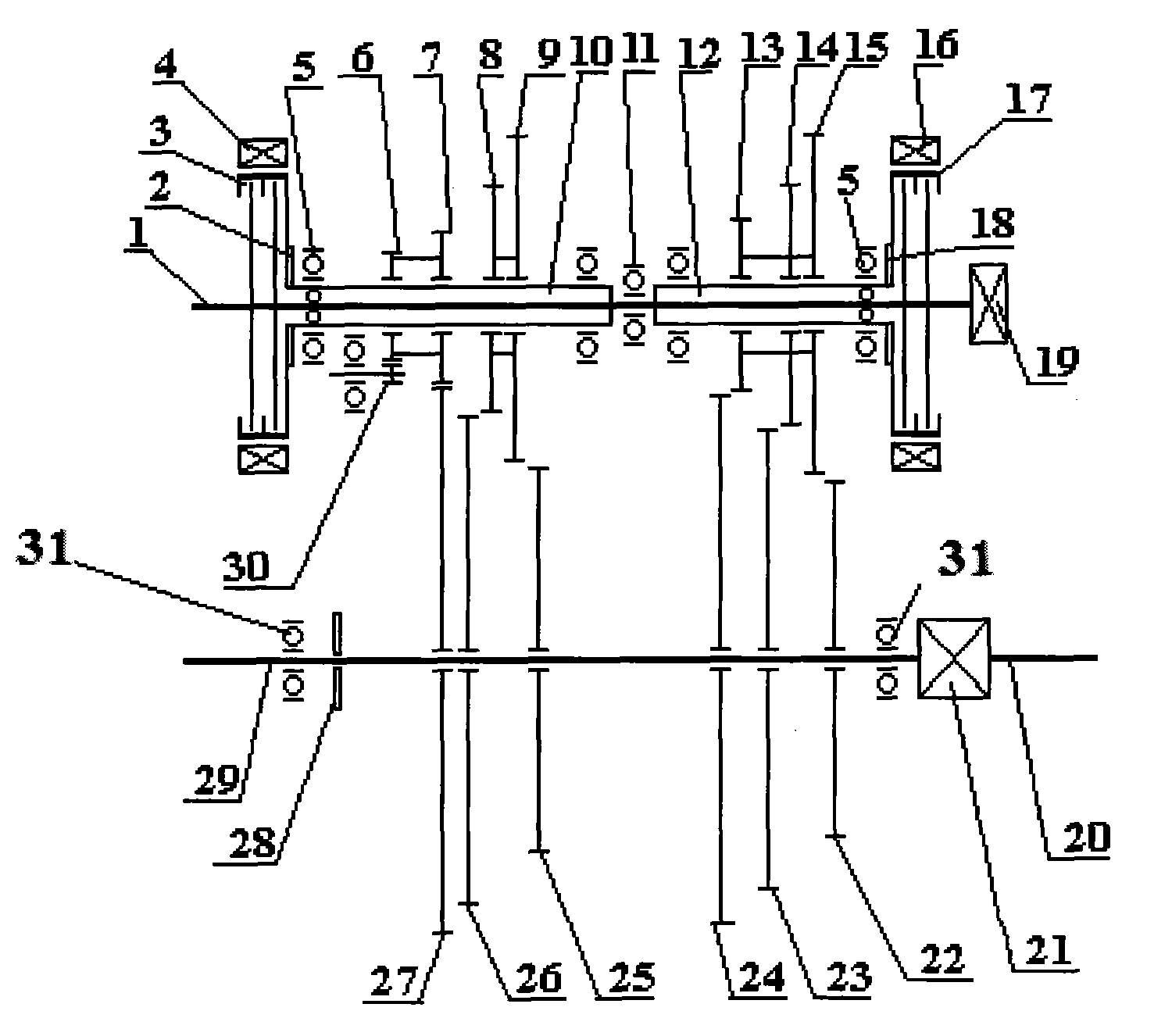

[0026] see figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the present invention, including a dual-clutch automatic transmission with six forward gears and one reverse gear. It includes an input shaft 1, a reverse gear reversing shaft and a power output device. One end of the input shaft 1 is connected to the power output end of the engine, and the other end is connected to the power input end of the oil pump 19; The first main shaft 10 and the second main shaft 12 arranged coaxially, the first main shaft 10 and the second main shaft 12 are hollow shafts, and a supporting bearing 11 is installed on the input shaft 1 between the first main shaft 10 and the second main shaft 12; Both ends of a main shaft 10 and a second main shaft 12 are fixed by support bearings 5 respectively; the input shaft 1 is a solid straight shaft passing through the first clutch 3 and the second clutch 17 .

[0027] The first main shaft 10 is provided with the first clut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com