Leather cutting machine

A cutting machine, leather technology, applied in leather punching/punching/cutting, small raw hide/large raw hide/leather/fur mechanical processing, small raw hide/large raw hide/leather/fur processing, etc. It requires rapid market response, low efficiency and high cost to achieve the effect of saving leather utilization, high efficiency and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

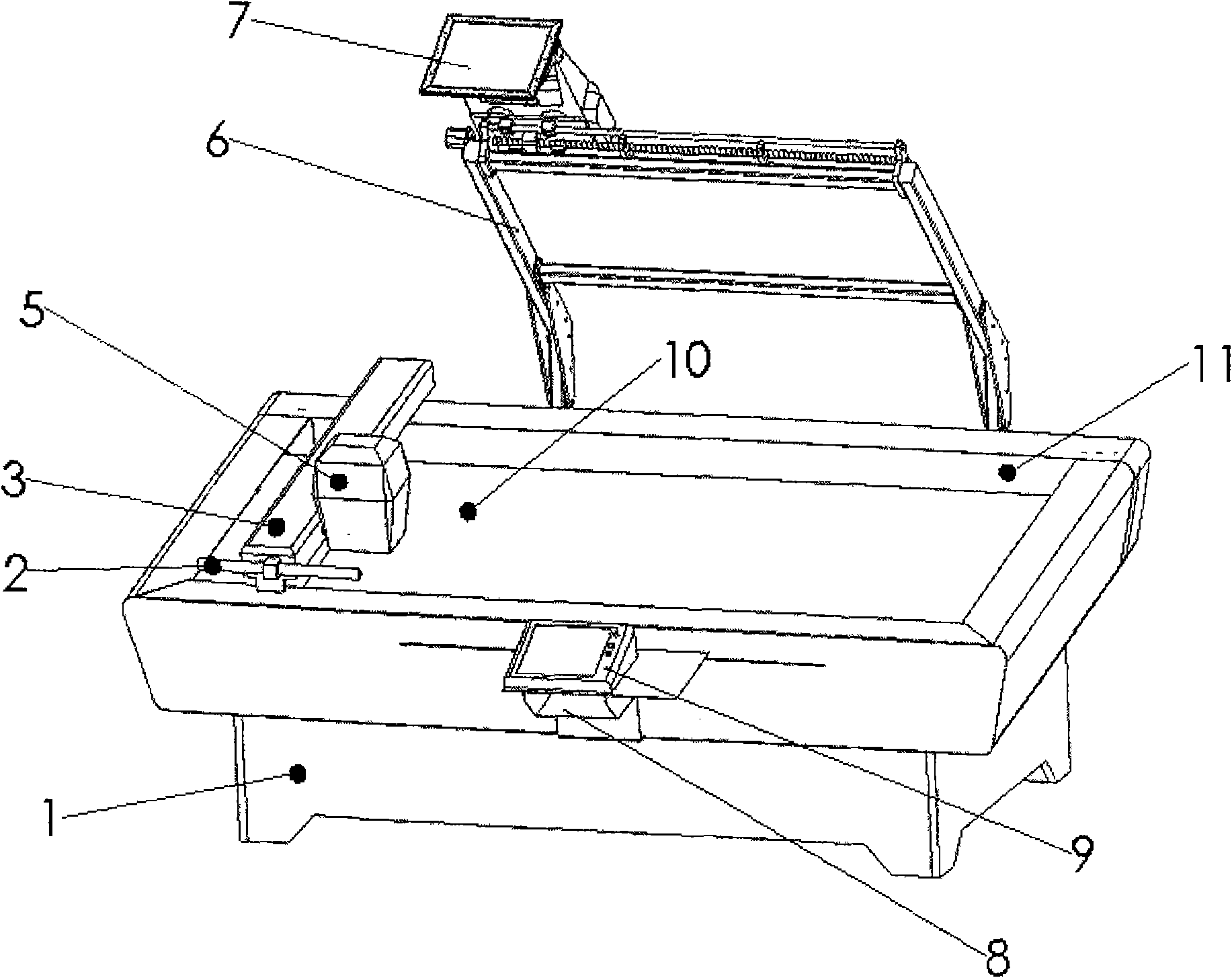

[0016] Such as figure 1 As shown in , it is a preferred embodiment of the present invention. A workbench 10 is arranged above the underframe 1. The underframe 1 is the load-bearing foundation of the entire cutting machine. Four adjustable Horizontal shock-absorbing pads (not shown in the figure), the upper surface of the workbench 10 is at a forward angle of 10° to the horizontal, which is convenient for the staff to operate, and the upper surface includes a cutting work area made of MDF And the adsorption area made of galvanized punching plate, the cutting work area and the adsorption area are distributed alternately, the cutting work area is painted with varnish, and there are 40 rows on the punching plate in the adsorption area. Air holes, each exhaust hole is airtightly connected with a solenoid valve and a vacuum tube, and the vacuum tubes are all connected with a manifold on a high-power vacuum pump. The adsorption area adopts a partial vacuum method, and the leather to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com