Integral molding technique and molding system for supersized composite material member

A composite material component and integral molding technology, which is applied in the molding process and system field of composite material components, can solve the problems of resin system waste, uneven rubber mixing, and increased viscosity of the resin system, so as to improve quality and efficiency and improve production environment, the effect of increasing the impregnation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Preparation of a large-scale composite wind turbine blade shell

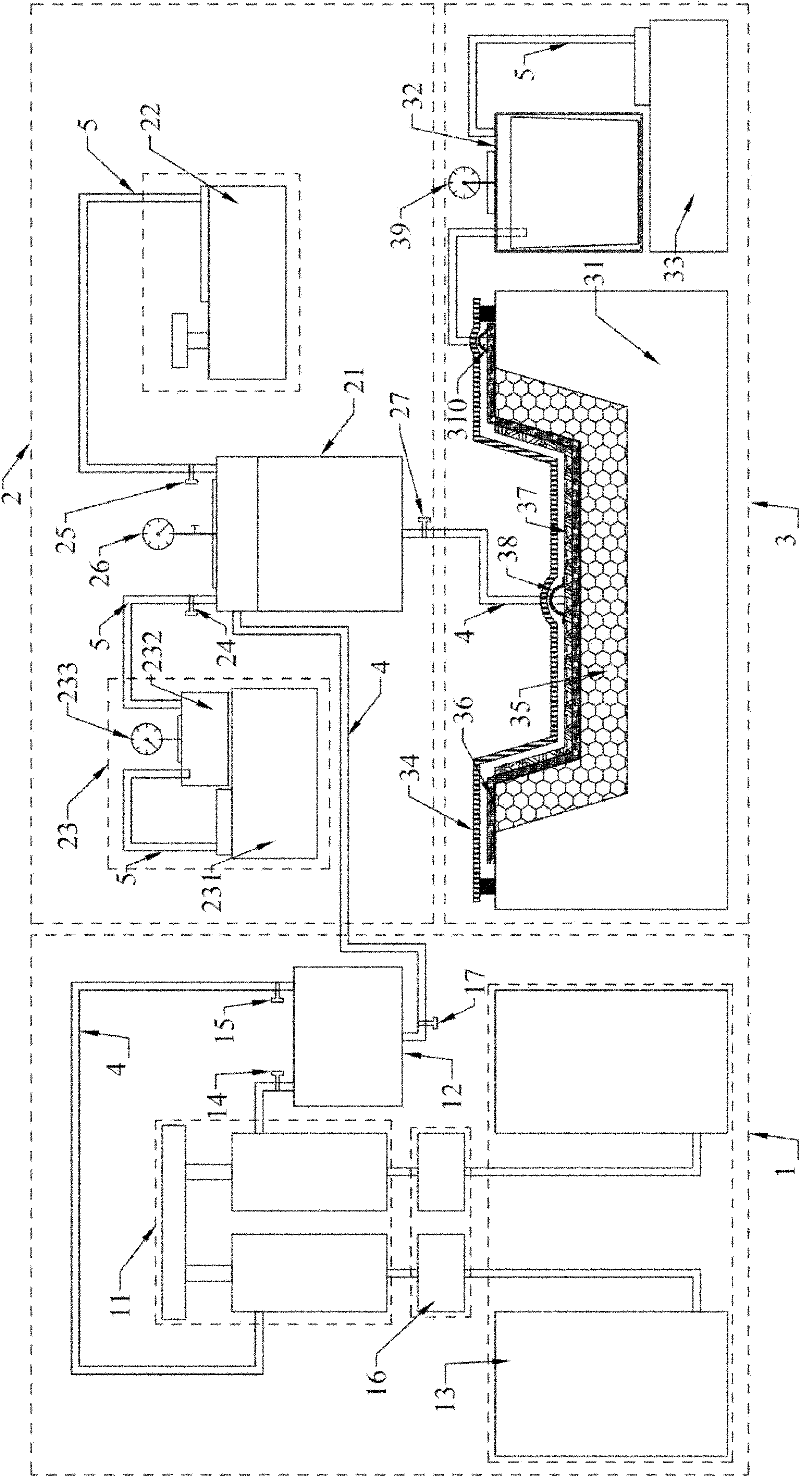

[0024] In the preparation process of this embodiment, a kind of such as figure 1 The molding system of the present invention shown includes an automatic rubber mixing system 1 , a defoaming and pressure regulating buffer system 2 and a vacuum infusion system 3 .

[0025] The automatic glue mixing system 1 includes a transfer pump 11, a glue mixer 12 and two raw material containers 13, and the two raw material containers 13 are respectively filled with resin and curing agent (the resin system selected for the preparation of the wind turbine blade shell in this embodiment is The blade special-purpose epoxy resin 1564 that Huntsman company provides and curing agent 3486), two raw material containers 13 are respectively communicated with the feeding port of glue mixer 12 through transfer pump 11 respectively by respective conveying pipeline 4, near the glue mixer 12 A first feed valve 14 and a sec...

Embodiment 2

[0035] Embodiment 2: Preparation of large FRP composite material hull

[0036]The preparation process of this embodiment uses a molding system whose composition and structure are the same as those of the molding system in Example 1, except that the "resin system" filled in the raw material container of the molding system of Example 1 is replaced by "preparation Commonly used polyester resins and corresponding curing agents for ship hulls" (the polyester resin selected in this example is Synolite 4082-G-22 unsaturated polyester resin provided by Jinling DSM, and the curing agent selected is commercially available methyl ethyl ketone peroxide Hardener).

[0037] The preparation process of the above-mentioned large FRP composite hull is as follows: image 3 As shown, the operation sequence of its steps is slightly different from that of Example 1, that is, step 1 and steps 2 to 4 are carried out simultaneously, and the specific operation method of each step is:

[0038] Vacuum ...

Embodiment 3

[0042] Embodiment 3: Preparation of train FRP top cover

[0043] The preparation process of this embodiment uses a molding system whose composition and structure are the same as those of the molding system in Example 1, except that the "resin system" filled in the raw material container of the molding system of Example 1 is replaced by "train Commonly used flame retardant resin and corresponding curing agent for top cover preparation" (the flame retardant resin selected in this example is KINETIXR118 epoxy resin and supporting curing agent system provided by Colas Company).

[0044] The preparation process of the above-mentioned train FRP top cover is the same as in Example 1, and the specific operation method of each step is:

[0045] First, prepare the infusion molding mold for the train roof, and clean the mold to make it smooth; then check the airtightness of the mold, spray the release agent on the surface of the mold after meeting the requirements, and then spray the gel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com