Processing box

A technology for processing cartridges and sliding elements, which can be used in electrography, optics, instruments, etc., to solve problems such as toner leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

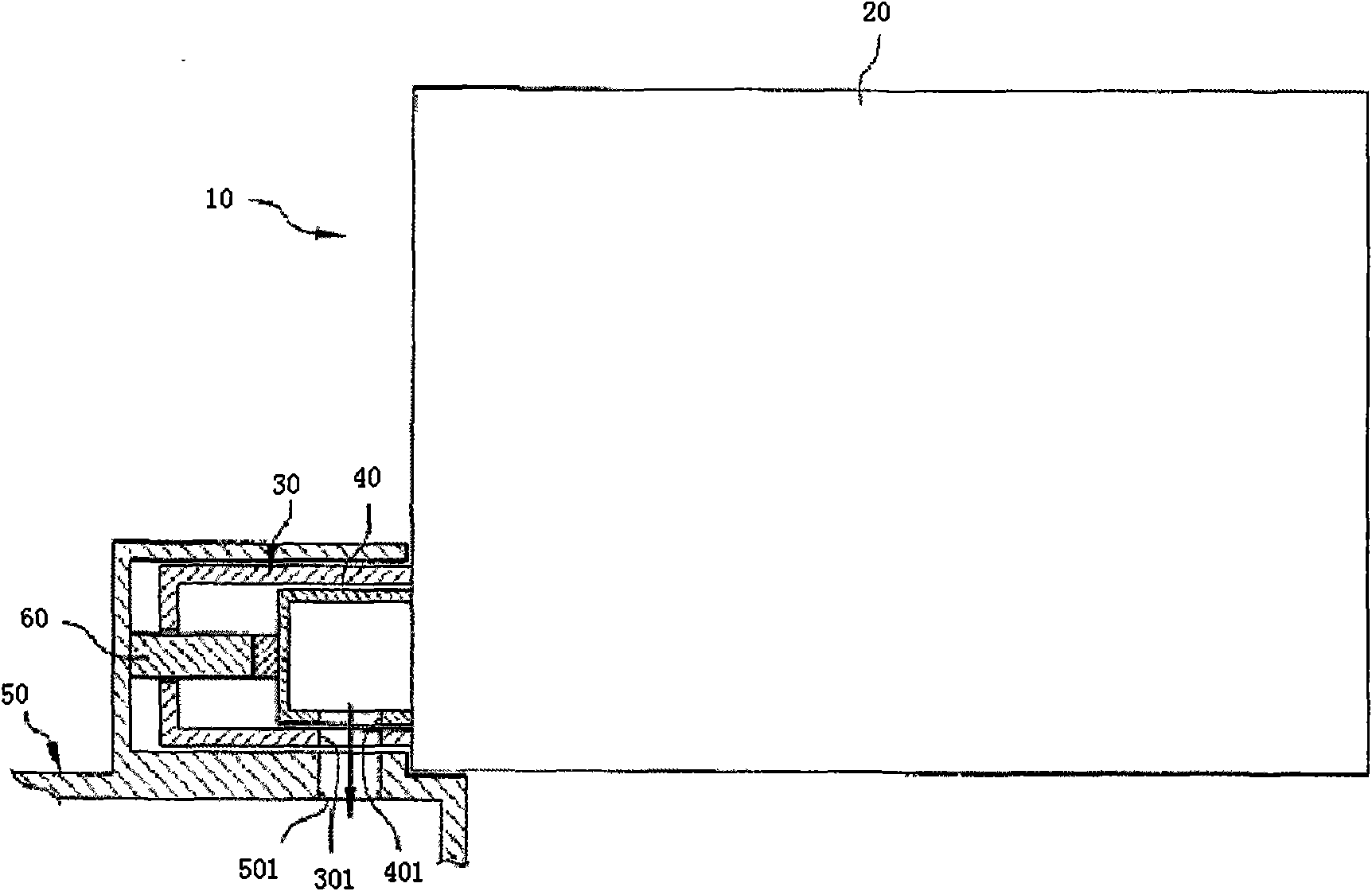

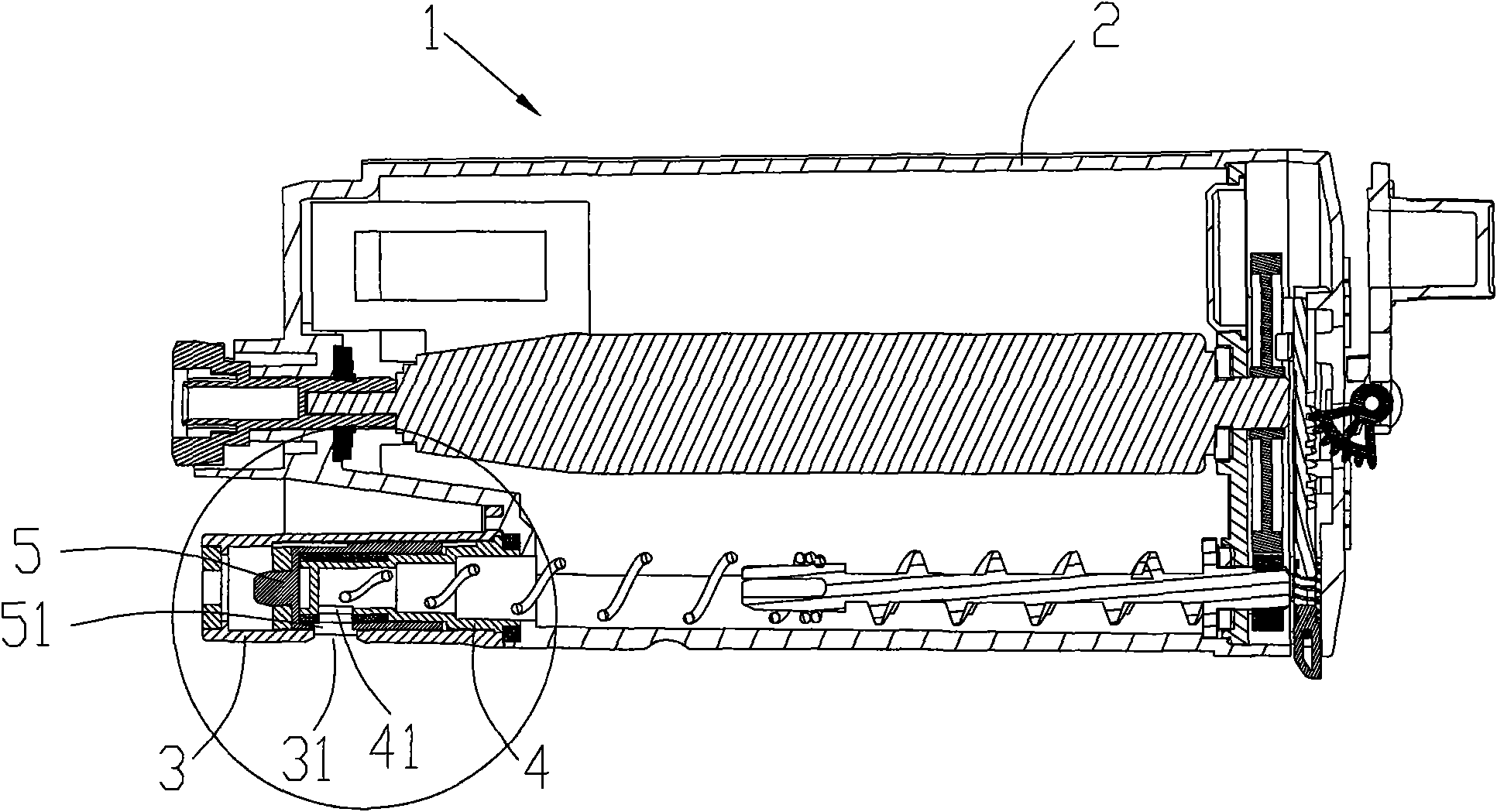

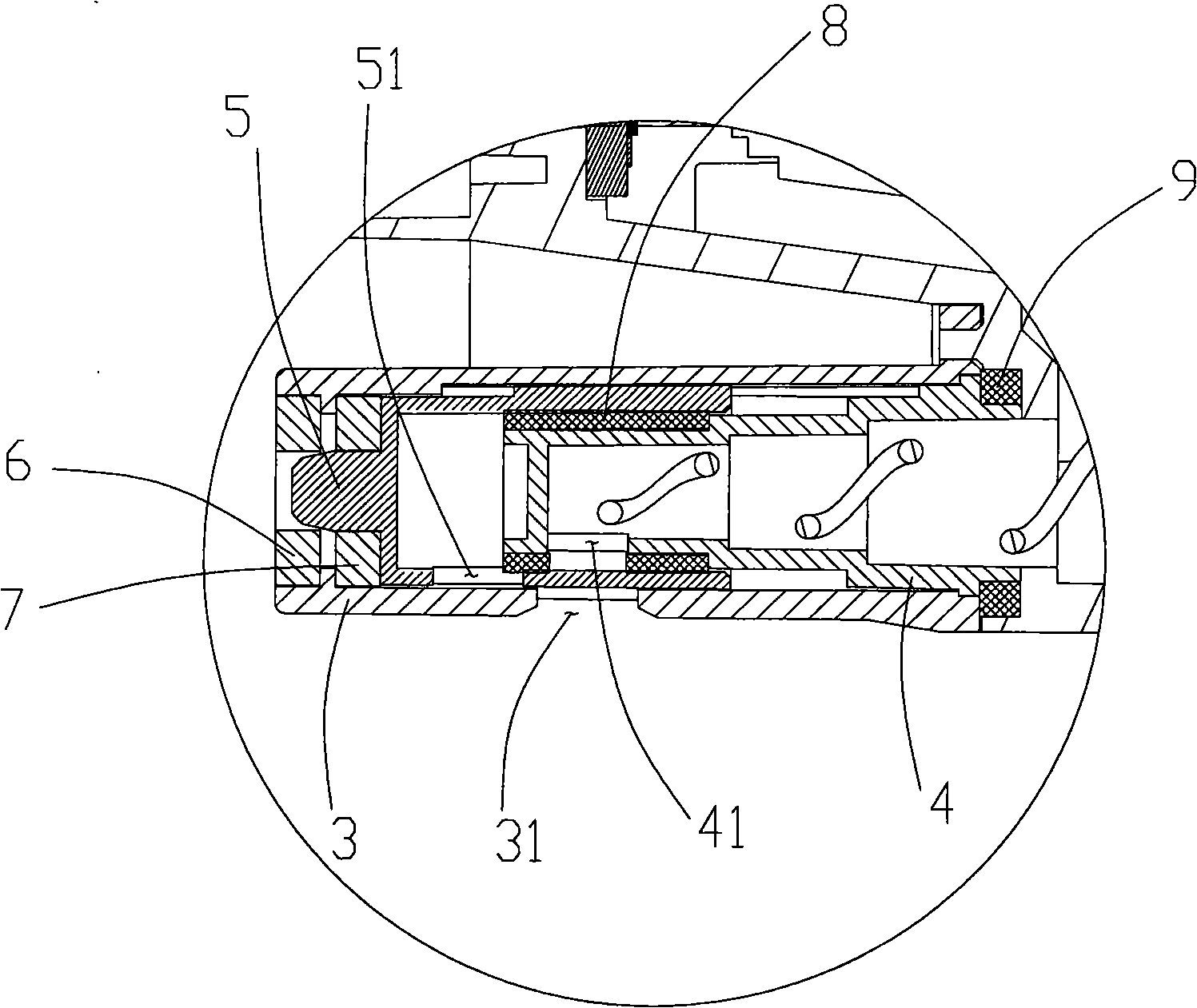

[0021] Such as figure 2 As shown, the process box 1 includes: a powder cylinder 2, a powder outlet part 3, an internal element 4 and a sliding element 5, the powder cylinder 2 is in the shape of a cylinder, and carbon powder is stored therein; the carbon powder can be transported to the powder outlet part 3 .

[0022] The powder outlet part 3 is arranged at the front end of the powder cylinder 2, and cooperates with corresponding components on the electrophotographic imaging system to provide carbon powder for the electrophotographic imaging system. There is a powder outlet 31 on the powder outlet part 3 .

[0023] There is an internal element 4 inside the powder outlet part 3, the internal element 4 is fixed inside the powder outlet part 3, and forms a certain space with the powder outlet part 3, and an internal powder feeding port 41 is arranged on the internal element 4.

[0024] Internal powder feeding port 41 such as figure 2 set on the circumferential surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com