Closed reciprocating compressor

A reciprocating and compressor technology, applied in the field of hermetic reciprocating compressors, can solve the problems of friction and wear, and the compressor cannot be driven normally, and achieve the effect of reducing friction and wear, improving reliability and maintaining normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

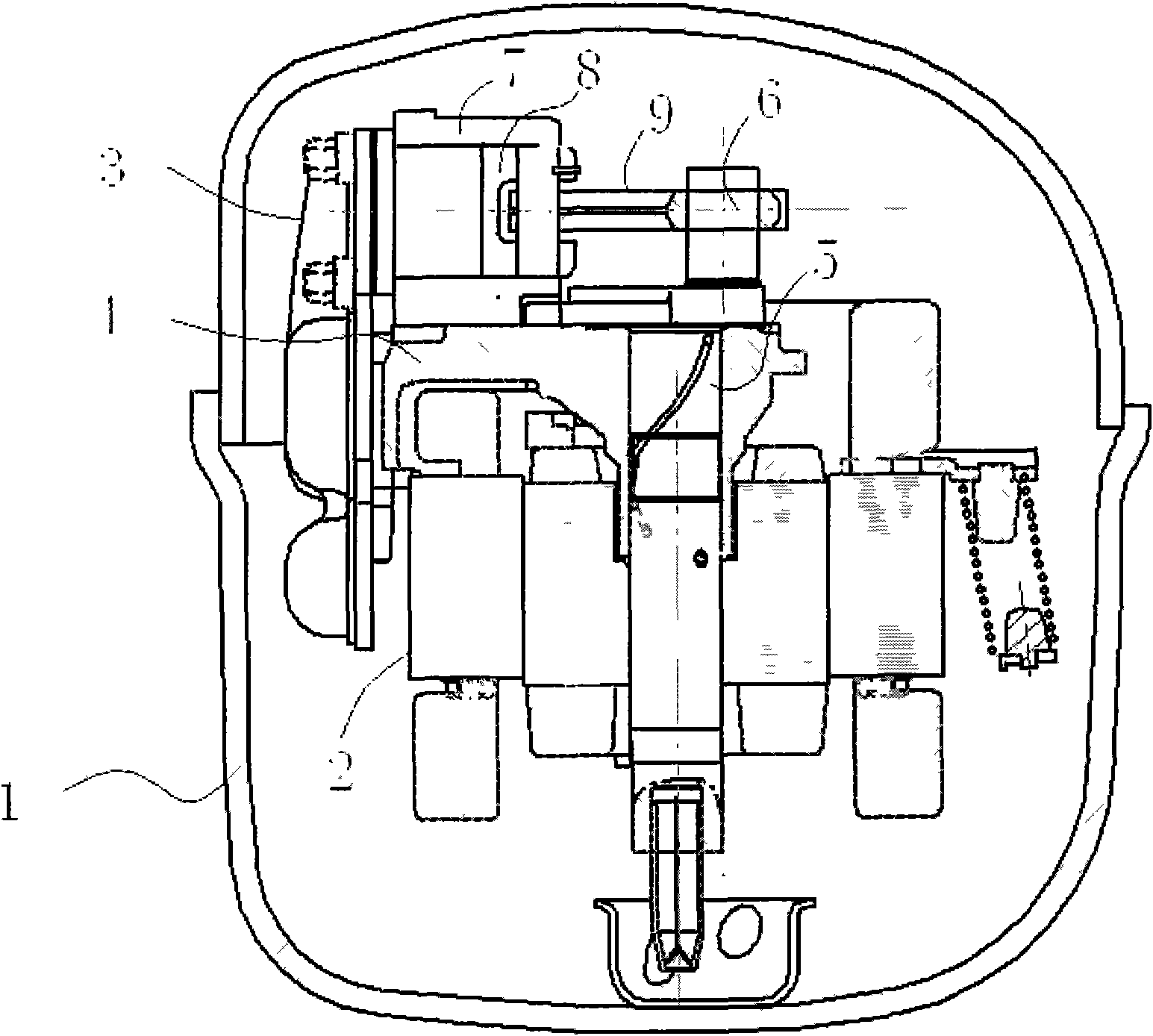

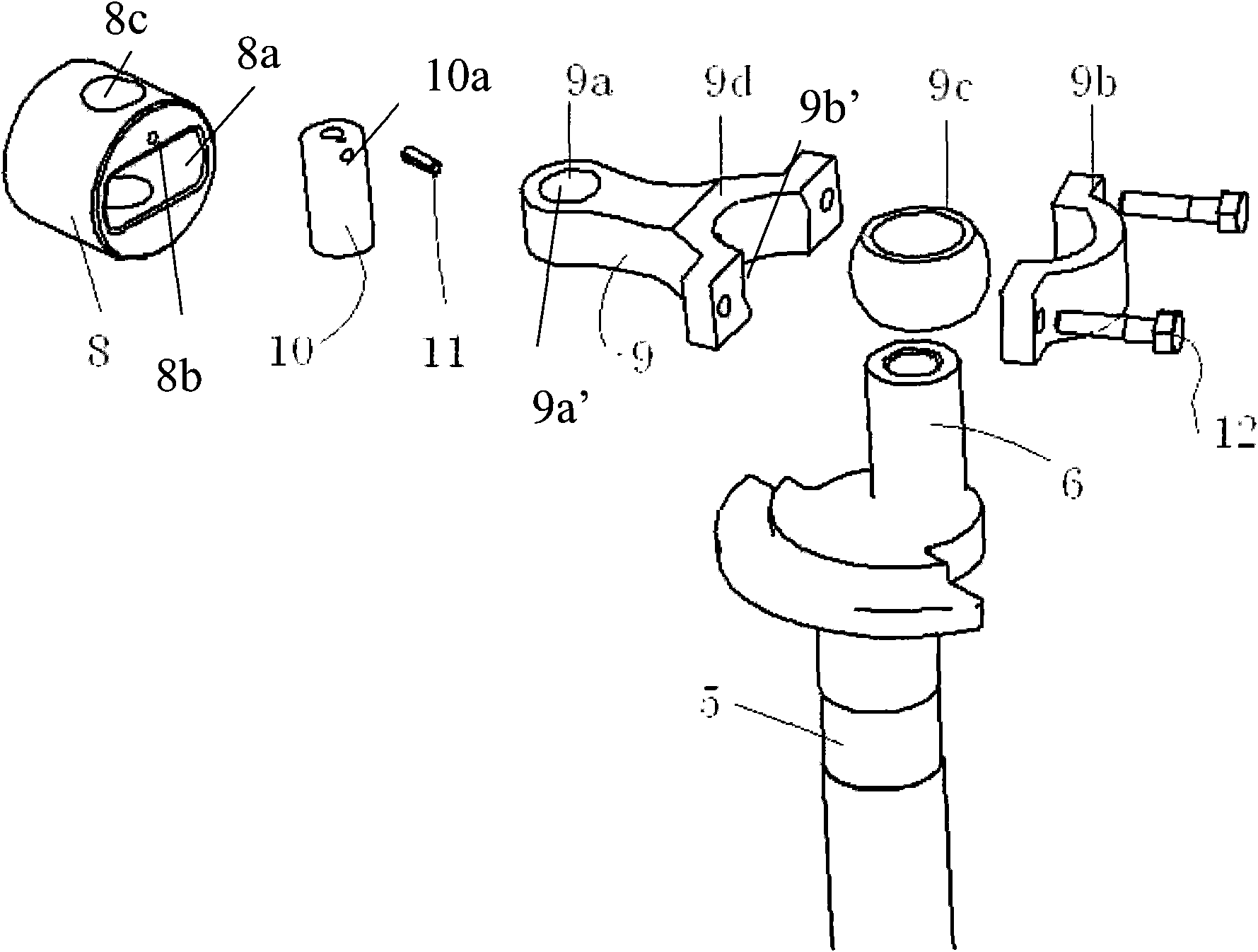

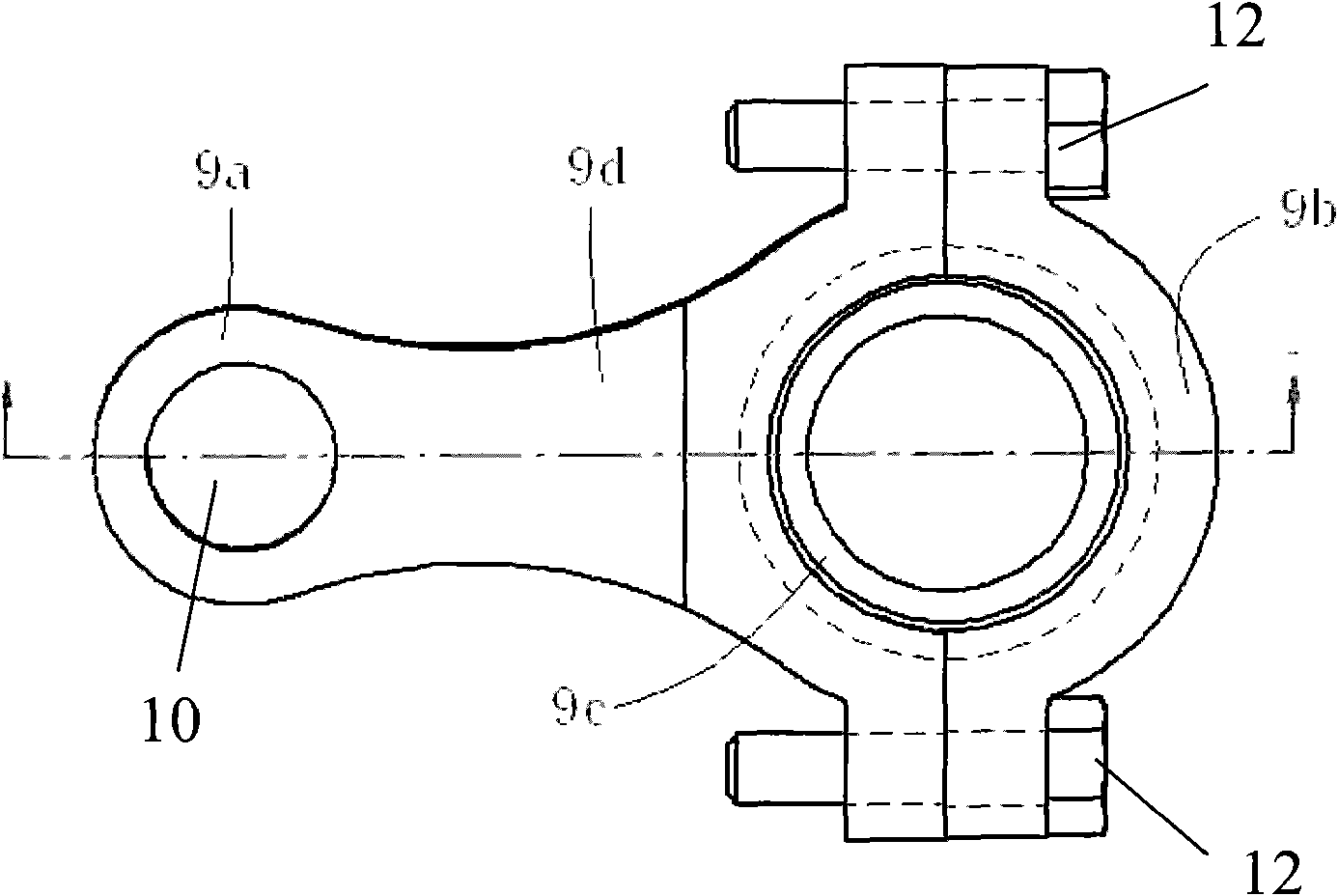

[0017] see Figure 1 to Figure 4 , a hermetic reciprocating compressor of the present invention comprises a hermetic container 1, a motor 2, a compression mechanism 3, a frame 4, a crankshaft 5 and a connecting rod device, wherein the motor 2 and a compression mechanism 3 Set inside the airtight container 1, the motor 2 includes a stator and a rotor; the compression mechanism part 3 includes a cylinder 7 and a piston 8, and the piston 8 can slide freely along the inner wall of the cylinder; the frame 4 supports the motor 2 and the compression mechanism part 3 in the airtight container 1 The crankshaft 5 transmits the rotational force of the motor 2, its lower part is fixed at the center of the rotor of the motor 2, and the upper part has an eccentric part 6, which rotates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com