Efficient diamond drill for repairing concrete sleeper and fabricating method thereof

A diamond drill bit and the technology of its manufacturing method are applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., and can solve the problems that the caliber size is not suitable for repairing concrete sleepers, the production efficiency is low, and it cannot be used to repair concrete sleepers. Achieve the effect of reducing diamond content, low production efficiency, and not easy to be oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] 1), Press: XDFD-50A automatic press, working pressure: 50T;

[0064] 2), control system: automatic control system matched with the press, pressure accuracy 0.1MPa, temperature accuracy (expressed by current) 5A;

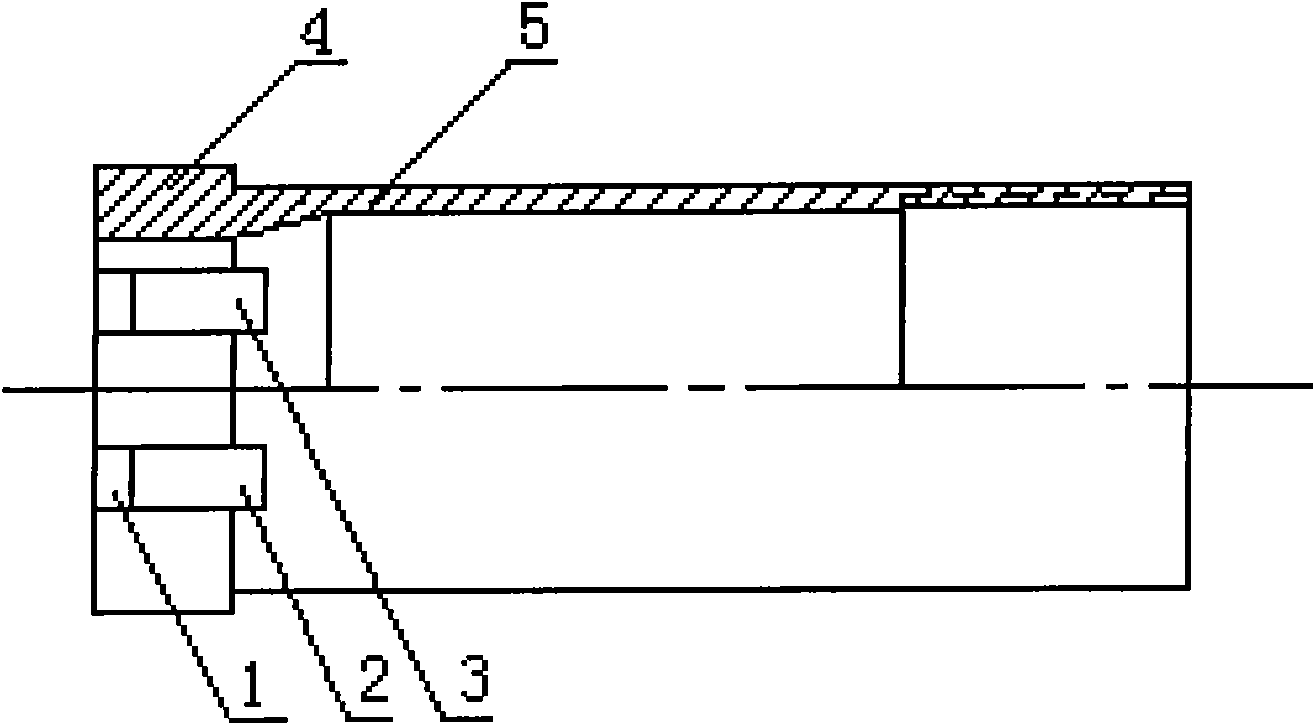

[0065] 3) Graphite molds; machined into high-precision molds for sintering drill bits with Φ25mm and outer diameter Φ35mm;

[0066] 4) Diamond: GBD120 type high quality diamond. Particle size: 40 / 50 and 50 / 60 mixed particle size, each 50%;

[0067] 5) The diameter of the drill bit is made; the inner diameter is Φ25mm, and the outer diameter is Φ35mm;

[0068] 6) Pressing hardness of metal powder: Mix the metal powder of the aforementioned framework material and the metal powder of the bonding material to make the hardness of the compaction: HRC25-30 carcass;

[0069] 7) Sintering temperature: control at 860-900℃;

[0070] 8), heat preservation time under pressure: 15 minutes;

[0071] 9) Cooling: Generally, take it out for mechanical processing until the next morn...

Embodiment 2

[0075] 1), Press: XDFD-50A automatic press, working pressure: 50T;

[0076] 2), control system: automatic control system matched with the press, pressure accuracy 0.1MPa, temperature accuracy (expressed by current) 5A;

[0077] 3) Graphite mold; machined into a high-precision mold for drill sintering with an inner diameter of Φ30mm and an outer diameter of Φ40mm;

[0078] 4) Diamond: GBD120 type high quality diamond. The particle size is: 40 / 50 and 50 / 60 mixed particle size, the ratio is 60%:40%;

[0079] 5) The diameter of the drill bit is made; the inner diameter is Φ30mm, and the outer diameter is Φ40mm.

[0080] 6) Pressing hardness of metal powder: Mix the metal powder of the aforementioned framework material and the metal powder of the bonding material to make it into a carcass with a hardness of HRC30-35;

[0081] 7) Sintering temperature: control at 900-920℃;

[0082] 8), heat preservation time under pressure: 15 minutes;

[0083] 9) Cooling: Generally, take it out for mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com