New technique for manufacturing high alloy steel seamless pipe with heavy calibre by adopting pilger mill

A high-alloy steel, seamless tube technology, applied in the direction of manufacturing tools, metal rolling, metal processing equipment, etc., can solve the problems of dimensional accuracy, surface quality, high cost, long process, etc. Equipment investment and operating costs, as well as the effect of floor space, reduced workload, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

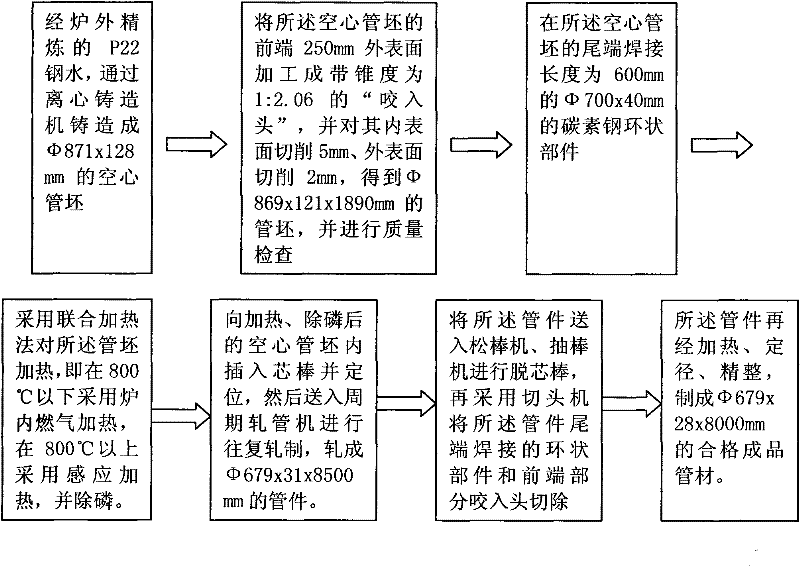

[0042] Such as image 3 Shown is a process flow diagram of an embodiment of the present invention, which specifically includes the following process steps:

[0043] In the first step, the high-pressure boiler tube refined outside the furnace is centrifugally cast with P22 molten steel through a centrifugal casting machine into a hollow tube blank of Φ871×128mm. In this step, the molten steel refined outside the furnace is the same as the prior art, and will not be repeated here; the centrifugal casting is carried out on a horizontal centrifugal casting machine with an angle of 0 degrees between the rotation axis of the mold and the horizontal. The cast hollow tube blank is a hollow tube blank with equal wall thickness and transparent ends. Using the centrifugal casting machine can conveniently and high-quality process the hollow tube billet used in the next step, without the need for heating, piercing and reaming of the continuous casting steel ingot in the prior art, which n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com