Electrically conductive, elastic compound thread, particularly for rfid textile labels, the use thereof, and the production of a woven fabric, knitted fabric, or meshwork therewith

A technology of composite thread and conductive thread, which is applied to the antenna of RFID textile tags, the production of fabrics, knitted fabrics and braided fabrics, and can solve the problems that it is impossible to have no interference, and the conductive function cannot be absolutely guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

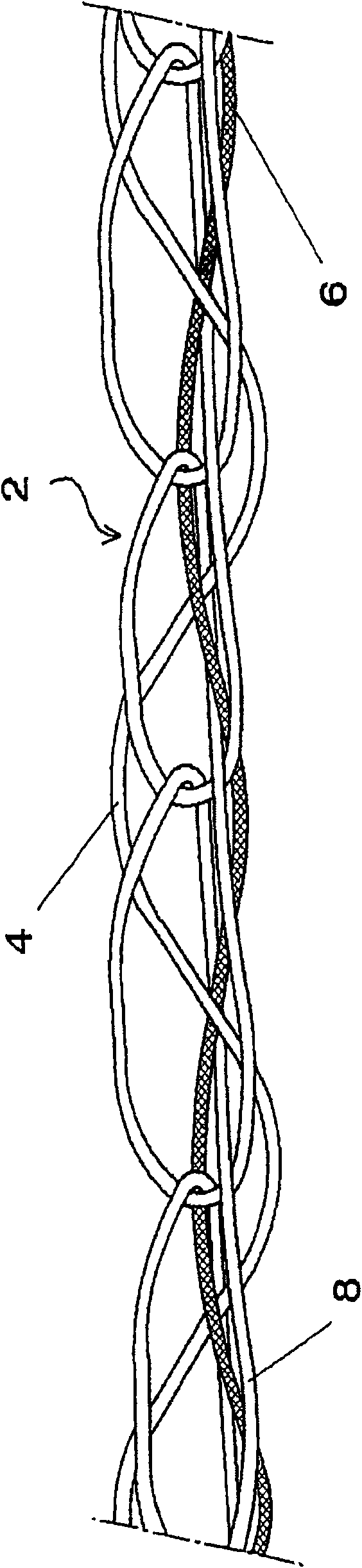

[0021] figure 1 A composite thread 2 according to a first embodiment of the invention is shown, in which a loose conductive thread 4 and a tension-relief thread 6 which is in tension compared to it are interwoven with a binding thread 8 . In other words, the tension relief wire 6 is in a state of higher tensile stress than the conductive wire 4 . The conductive thread 4 and the tension relief thread 6 are designed here such that the conductive thread 4 is subjected to a tensile load only at point a+b, at which point the tension relief thread 6 has reached its breaking limit 62 approximately at 28% elongation. In addition, the tensile strength of the tension relief thread 6 is greater than that of the conductive thread 4 . That is, this is equivalent to image 3 Case II of the breaking strength curve.

[0022] This composite thread 2 is produced on a knitting machine or a raschel machine. In this example, the composite thread has about 22 needles per cm. The tension relief...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com