Micromechanical terahertz waveguide, terahertz waveguide type resonant cavity and preparation method thereof

A terahertz, micro-mechanical technology, applied in optical waveguides, waveguides, resonators, etc., can solve the problems of difficult to ensure circuit operating characteristics and yield, long time consumption, high processing accuracy requirements, etc., to achieve large-scale parallelization Processing, shape flexibility and variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

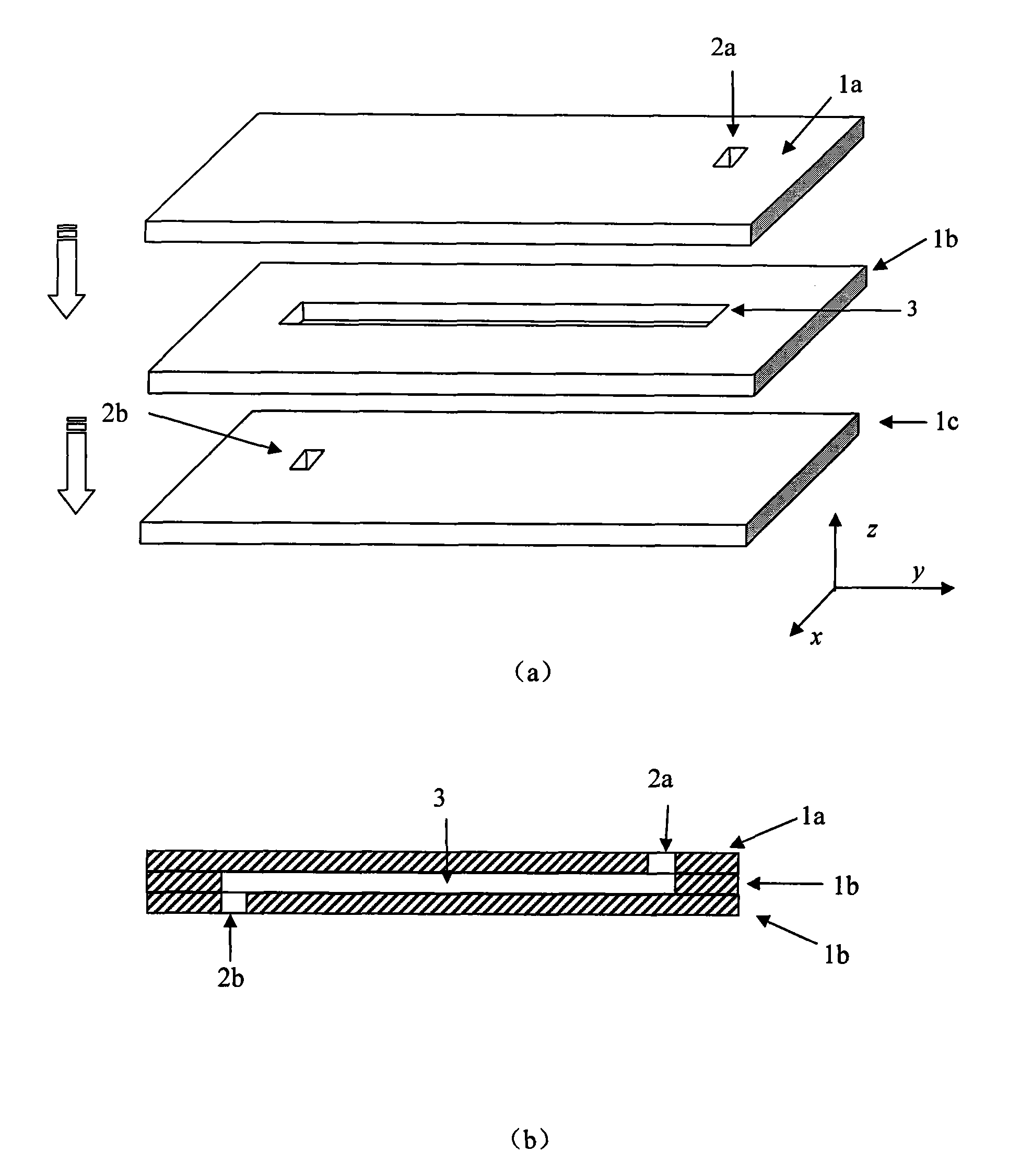

[0041] figure 1 The basic structure of the micromachined terahertz waveguide embedded in the low-temperature co-fired ceramic substrate of the present invention is shown. In the figure, the LTCC package substrate is composed of three layers of substrates 1a, 1b, and 1c. The above-mentioned flat substrates are stacked parallel to each other, and the upper surface plate 1a and the lower surface plate 1c are processed with a body-shaped micro-machining process. The waveguides 2a and 2b on the upper surface plate 1a and the lower surface plate 1c are used for signal input / output; the intermediate substrate 1b is made with a rectangular section waveguide 3 whose axis is parallel to the direction of the substrate, and all the inner walls of the waveguide are coated with High-conductivity metals such as Au, Ag or Cu are used to guide the THz electromag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com