Experimental device for evaporation, absorption and mass transferring of falling film of vertical tube

A technology of falling film evaporation and absorption heat transfer, applied in the direction of material heat development, material thermal conductivity, etc., can solve the problems of not being able to track and monitor temperature and pressure changes, not being able to conduct research at the same time, and being in a blank stage, etc., to achieve compact structure, The effect of intuitive image and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

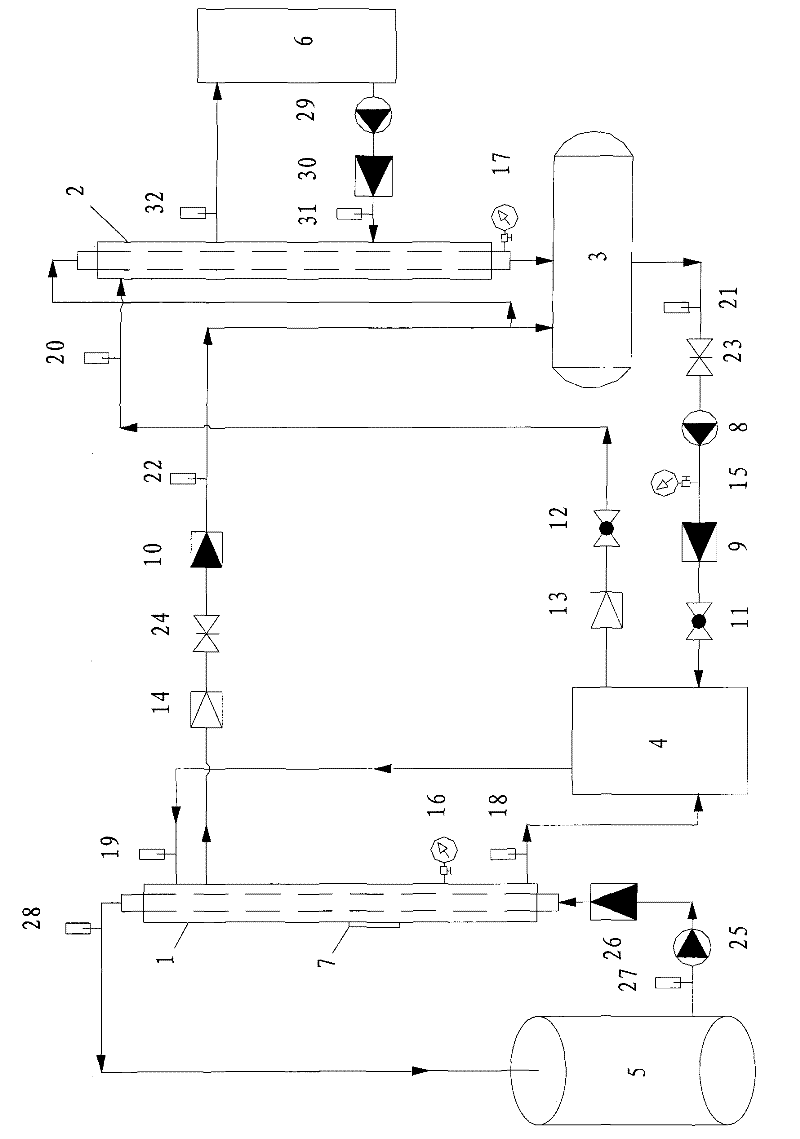

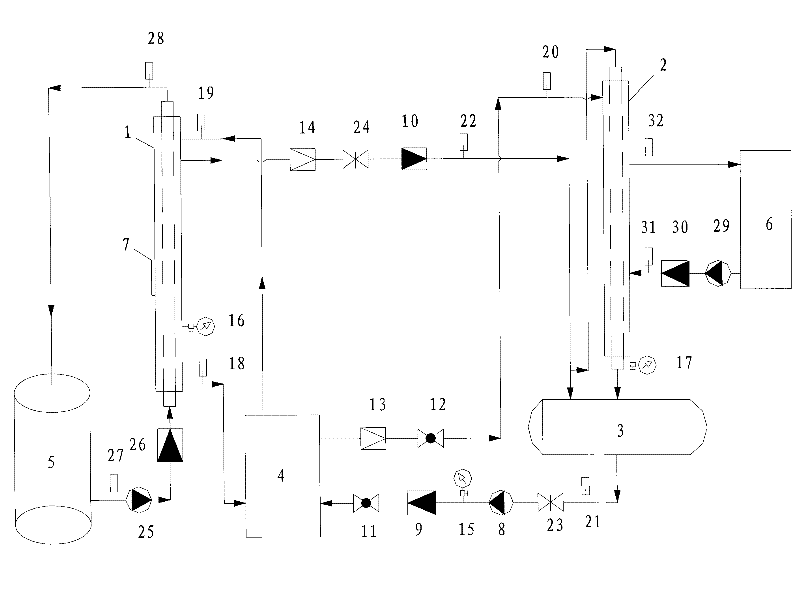

[0016] refer to figure 1 , a vertical tube falling film evaporation and absorption heat and mass transfer experimental device, comprising a vertical tube generator 1, a vertical tube absorber 2, a liquid storage tank 3, a heat exchanger 4, a pressure reducing valve 13 and a pressure reducing valve 14, The solution pump 8, the heating water tank 5, the hot water pump 25, the cooling tower 6, and the cooling water pump 29 are composed. The inlet of the solution pump 8 is connected to the bottom of the liquid storage tank 3 through a pipeline, and the outlet is connected to the first inlet of the heat exchanger 4 through a pipeline. The first outlet of the device 4 is connected to the working medium inlet of the standpipe generator 1 through a pipeline, and the gas phase outlet of the working medium of the standpipe generator 1 is connected to the liquid storage tank 3 and the standpipe absorber 2 through a pipeline after passing through the pressure reducing valve 14. The gas ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com