Absolute magnetic-electric rotary encoder with low cost, high accuracy and multiple circles

A rotary encoder, high-precision technology, applied in the direction of converting sensor output, instruments, measuring devices, etc., can solve the problems of inability to read position data, sensor humidity rise, blocking grating discs, etc., to simplify the installation structure and reduce the cost of use , the effect of extending the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

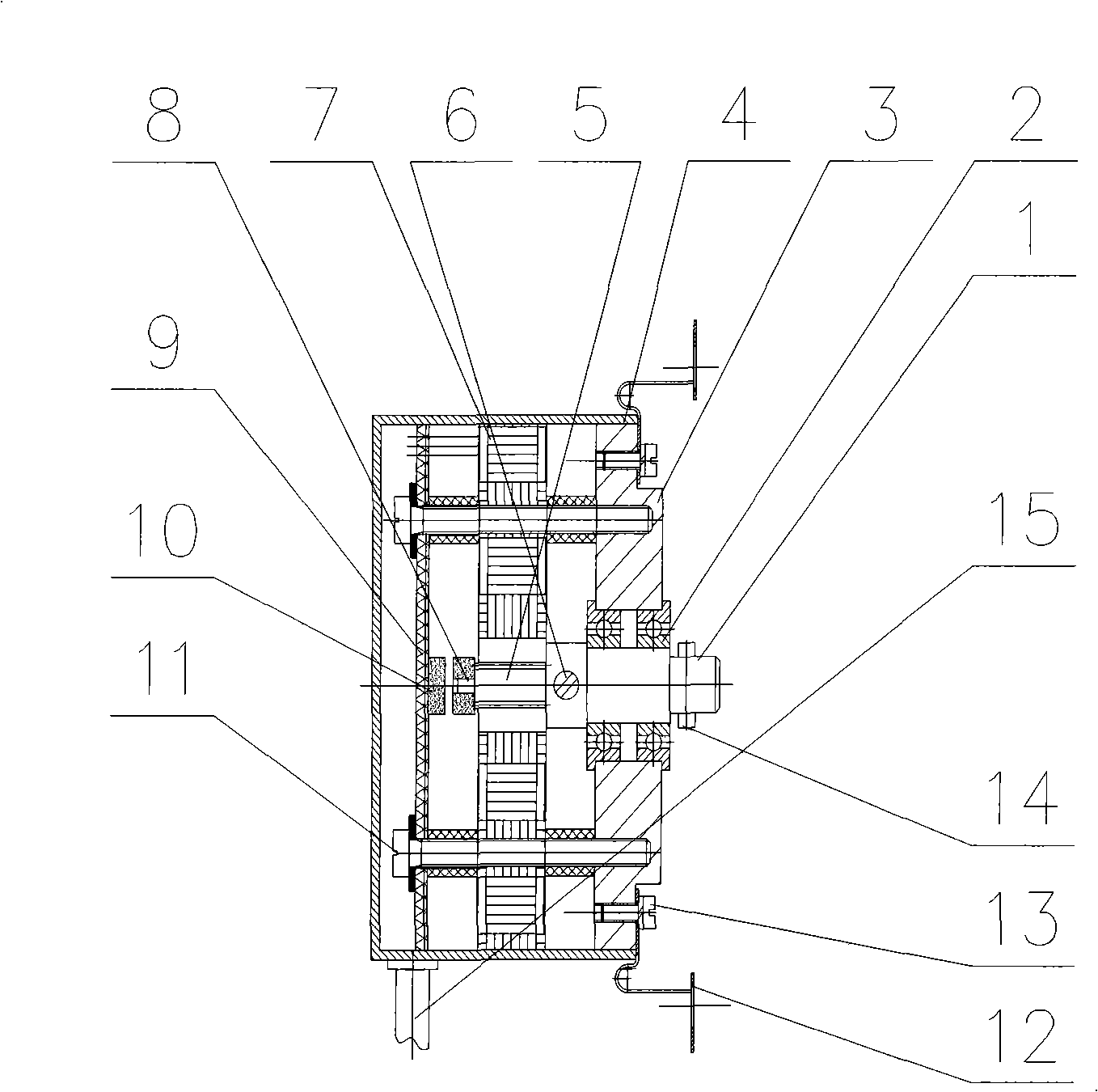

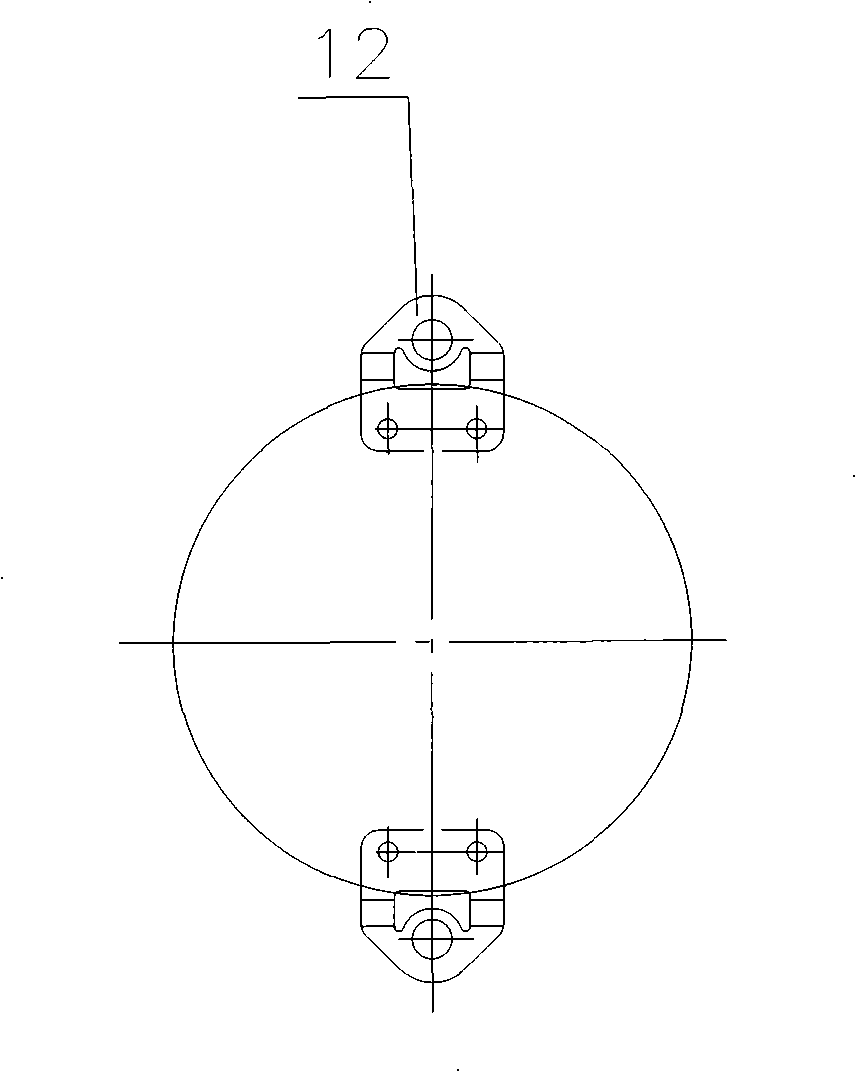

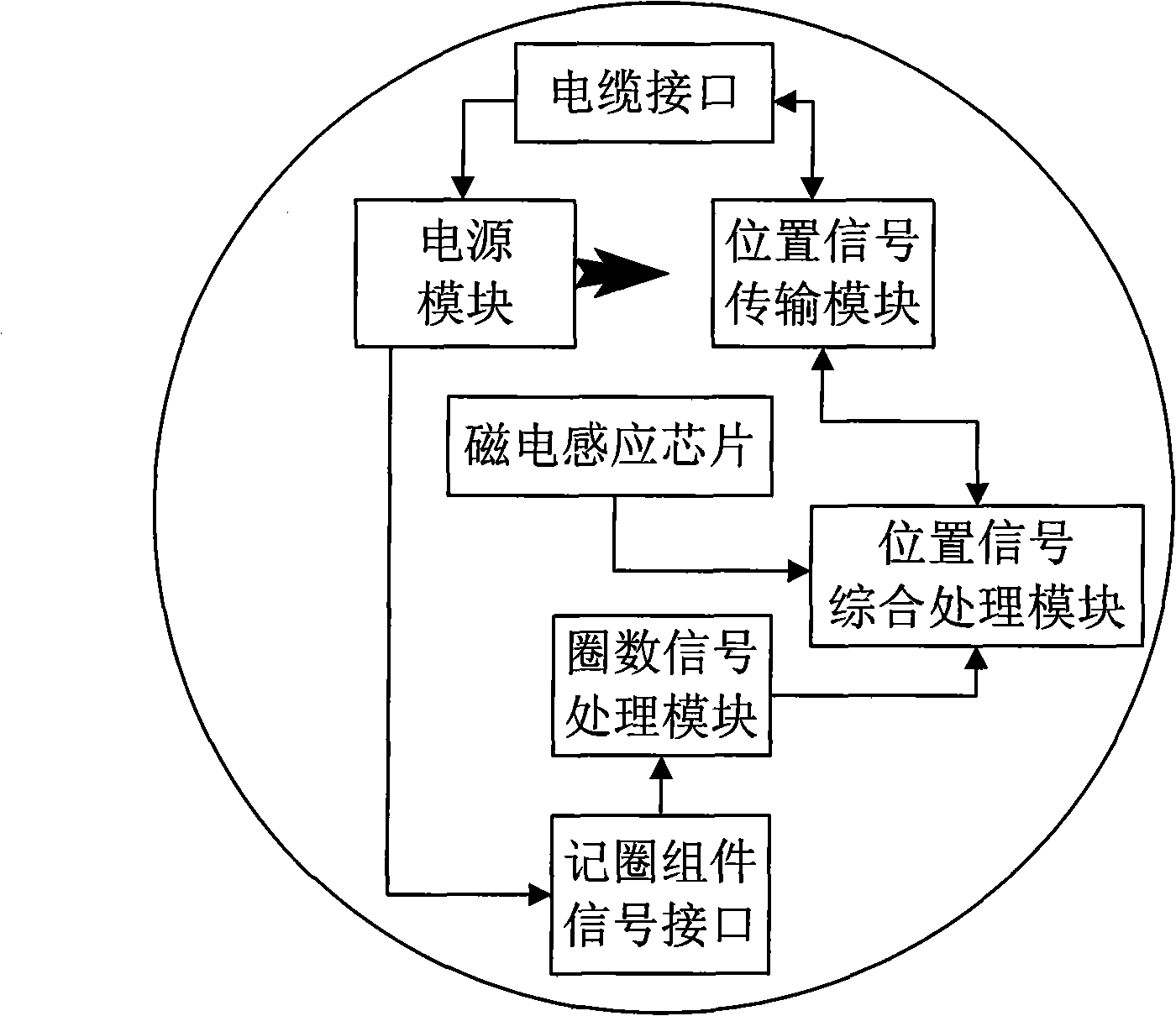

[0014] Combine below figure 1 , figure 2 and image 3 Shown, the present invention is described in further detail.

[0015] The present invention is mainly composed of a main shaft 1, a bearing 2, a main fixed base plate 3, a housing 4, a pinion shaft 5, a pinion shaft fixing screw 6, a ring assembly 7, an NdFeB cylindrical magnet 8, an integrated circuit board 9, and a magnetoelectric The induction chip 10, the overall fixed support screw 11, the elastic mounting plate 12, the elastic mounting plate fixing screw 13, the main shaft fixing pin 14, the cable 15 and the like are composed.

[0016] The present invention is mainly composed of four major parts, that is, the shaft system of the rotating part, the main fixed base plate, the lap assembly, and the integrated circuit board part.

[0017] Combine the main shaft 1 and the pinion shaft 5 with the end protruding part through the pinion shaft fixing screw 6 (or make the main shaft 1 and the pinion shaft 5 as a whole), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com