Application of anti-fluctuation diffusion curve in gas collecting pipe diffusion control device of coke furnace

A control device and gas collecting pipe technology, which is applied in the program control of sequence/logic controller, electrical program control, furnace safety device, etc., can solve the problems of inability to ensure timely ignition, difficulty in manual ignition, and high degree of danger to workers and other issues, to achieve the effects of reliable fire extinguishing, safe production, environmental adaptability improvement, and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Introduce the specific embodiment of the present invention in detail below

[0021] 1 The structure and working principle of the device

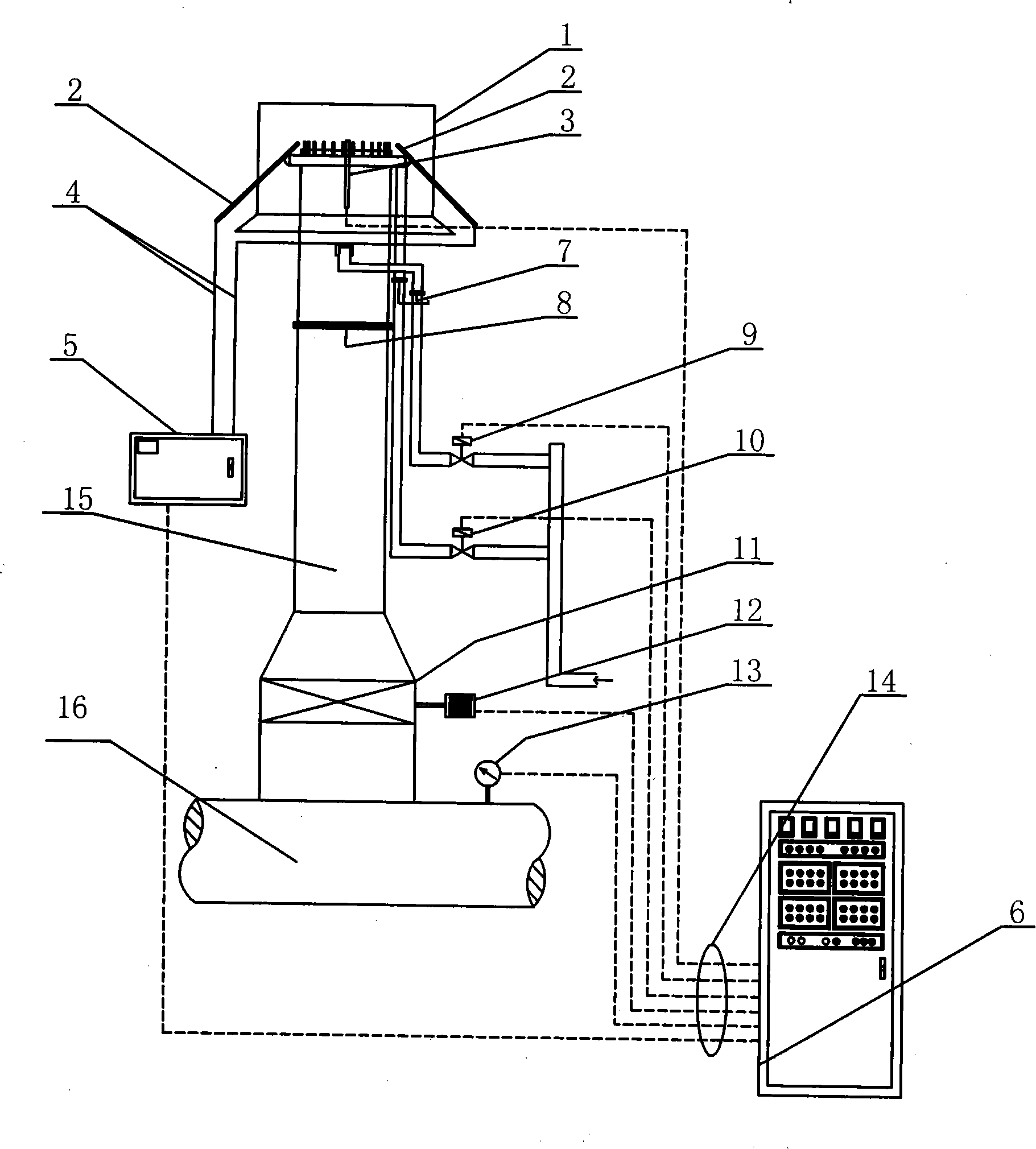

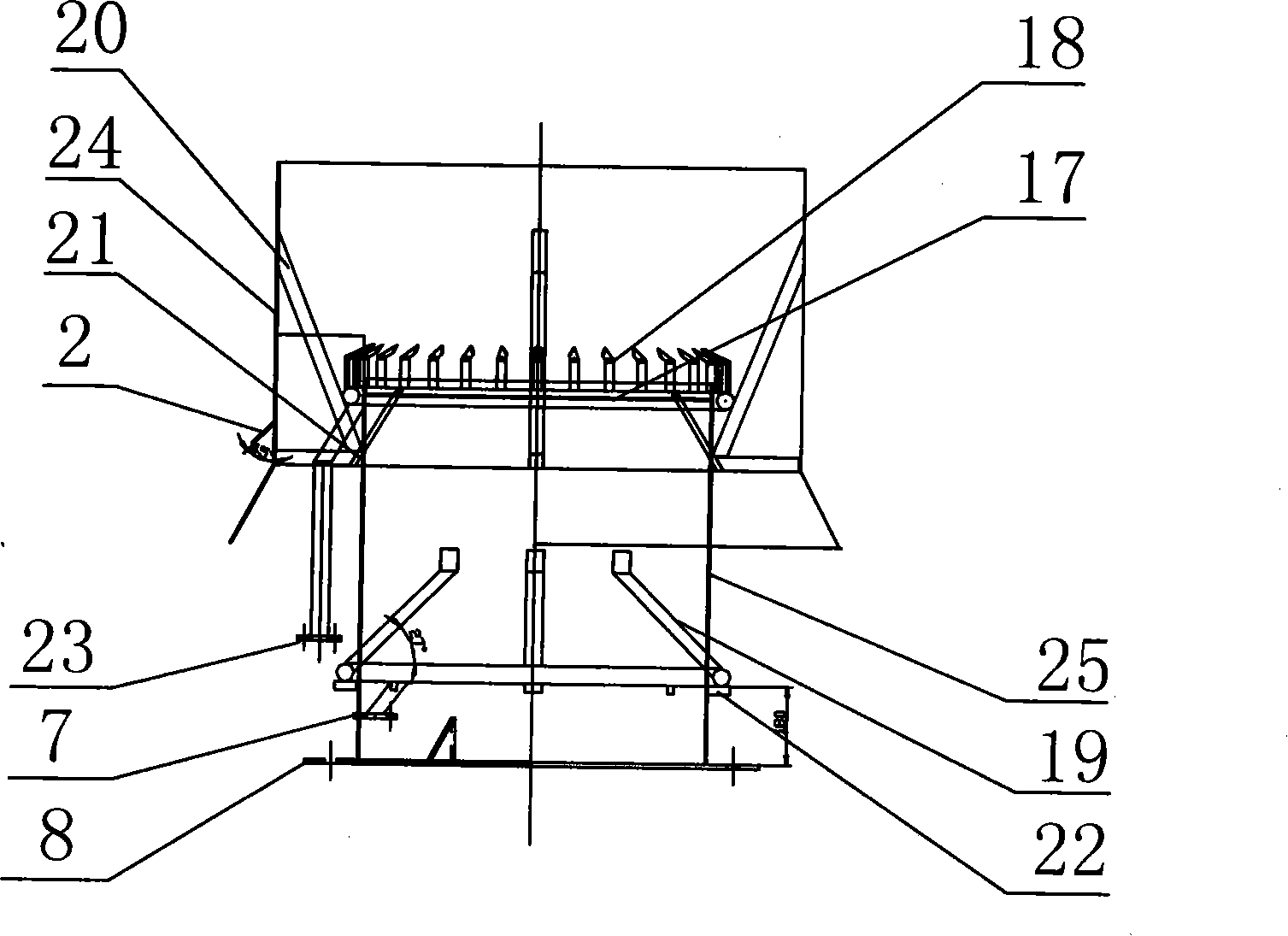

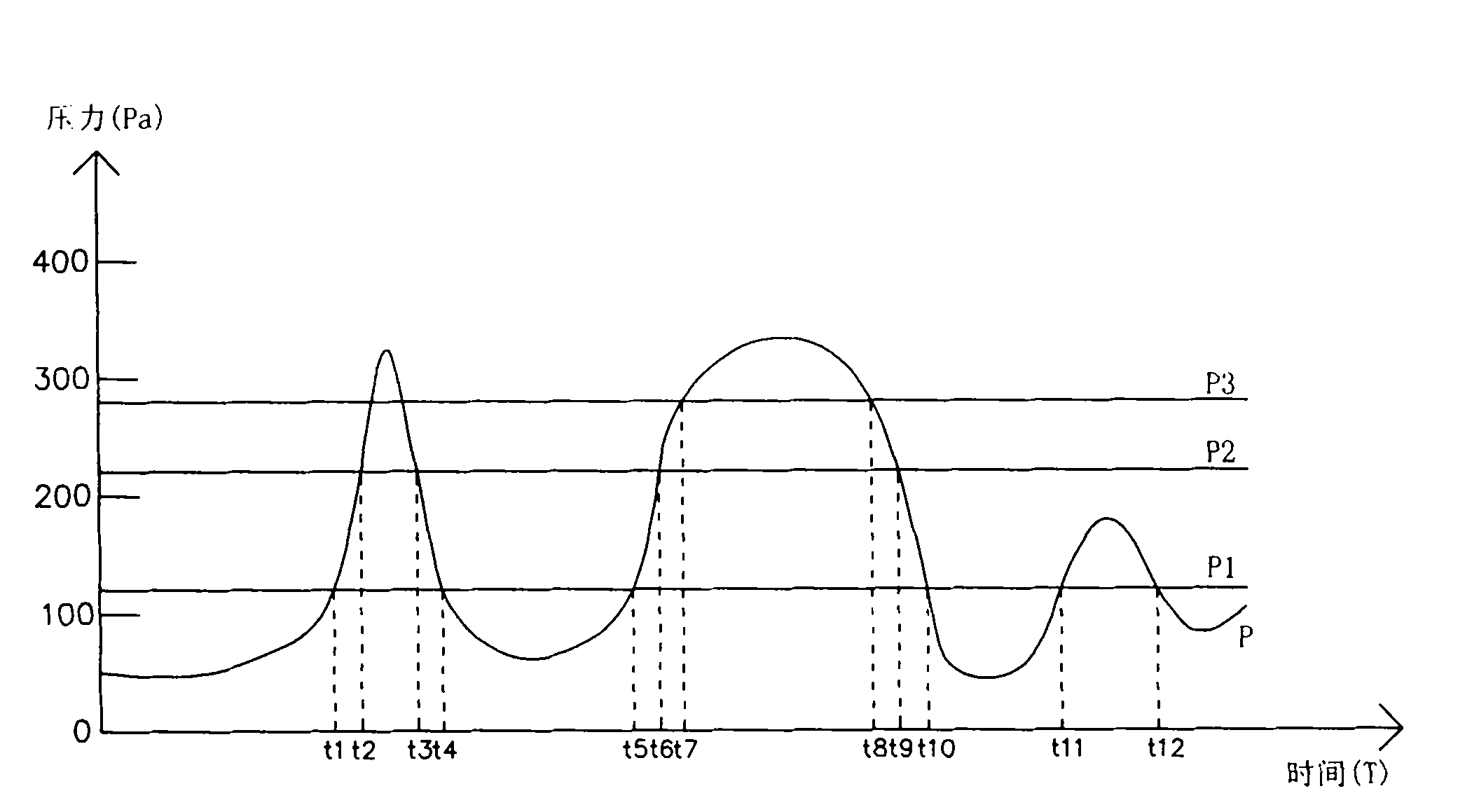

[0022] See figure 1 , coke oven gas collecting pipe release control device, the device consists of burner 1, release pipe 15, igniter cabinet 5, control cabinet 6, release valve 11, release valve actuator 12, fire closing valve 10, fire extinguishing valve 9, pressure variable The burner 1 is located on the upper part of the release pipe 15 and is connected by a large flange 8; the igniter cabinet 5 is connected to the ignition gun 2 on the burner 1 through a high-voltage shielded cable 4, and the fire closing valve 10 is connected to the burner to close the fire Tube 18 ( figure 2 ), the fire extinguishing valve is connected to the burner fire extinguishing pipe 19 ( figure 2 ); the release valve 11 is located at the junction of the discharge pipe 15 and the gas collection pipe 16, and is connected with the discharge valve actua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com