Cutting-grinding dual-purpose rock-processing system with double end faces

A processing system and double-end technology, applied in the direction of stone processing tools, stone processing equipment, metal processing equipment, etc., can solve the problems of unchanging rock sample processing, single function, clamping and crushing, etc., to achieve strong realizability and principle Simple, easy-to-maintain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

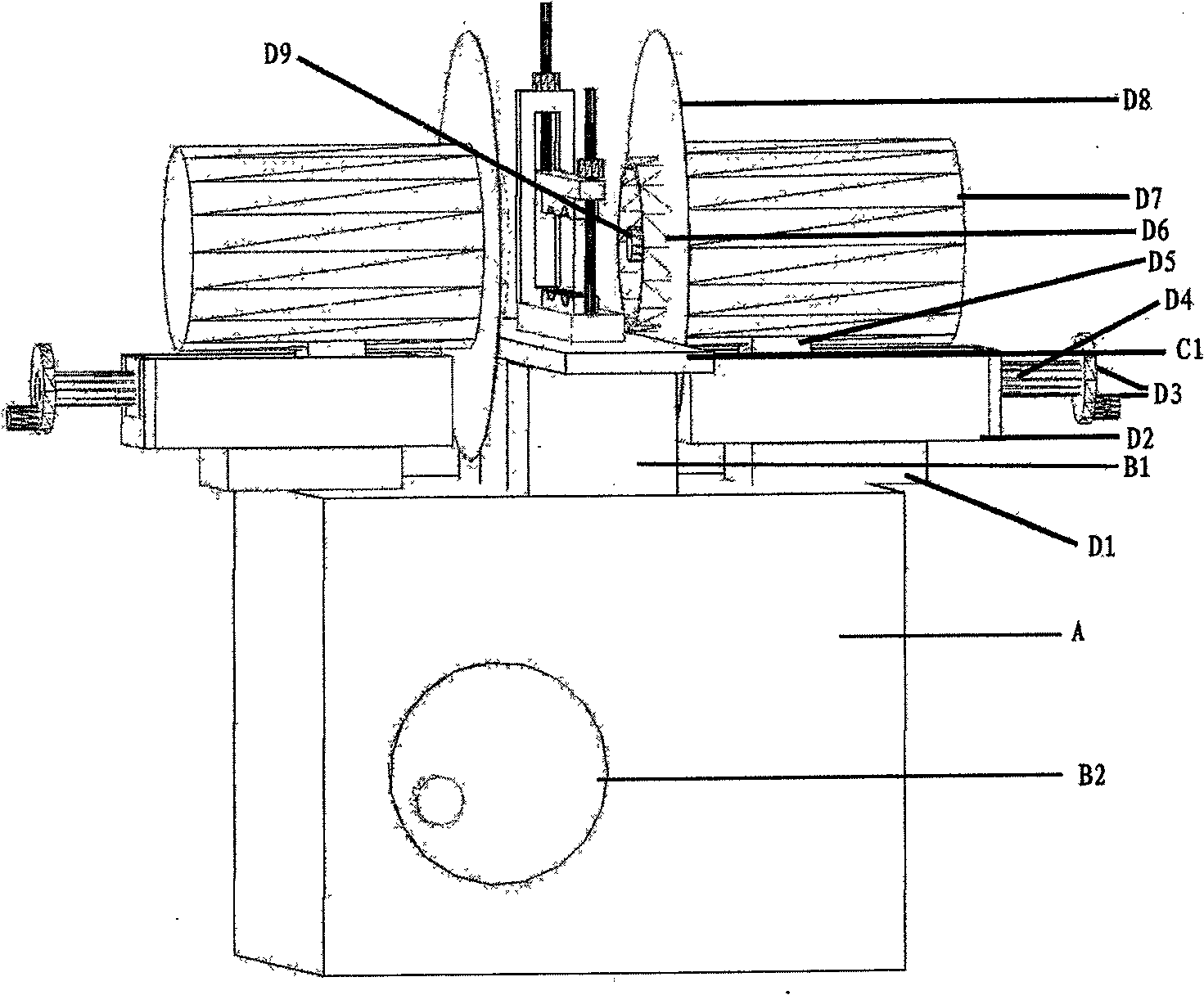

[0039] Attached below figure 1 , 2 and 3 detail how the invention is used.

[0040] (1) Equipment assembly:

[0041] 1) Place the base on a flat ground;

[0042] 2) Install the lift in the base, connect it with the lift knob, and test it;

[0043] 3) Place the pulley on the top of the lift;

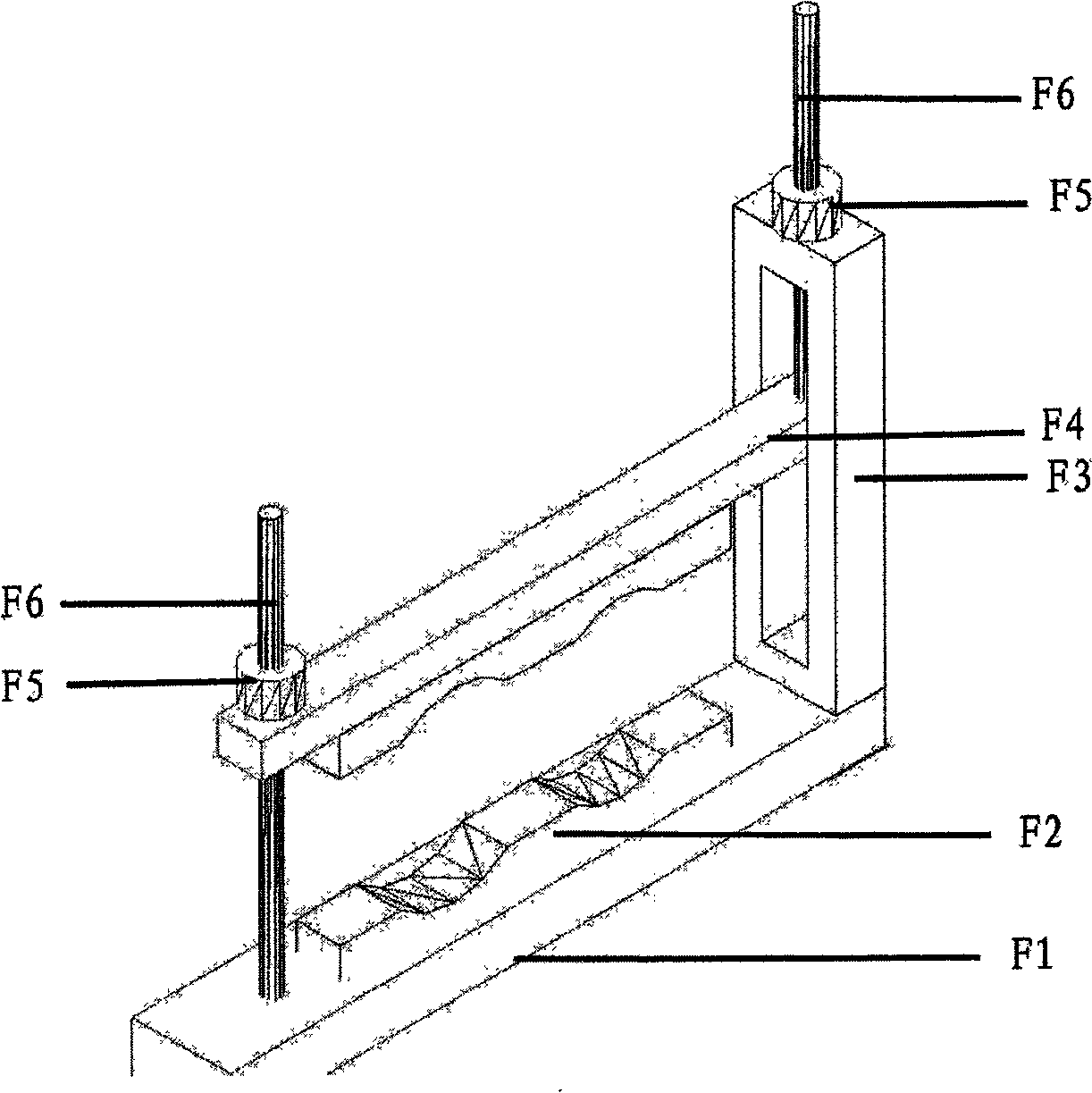

[0044] 4) Place the worktable on the pulley of the elevator, the slide rail and the pulley are well fitted, the gears and the tooth grooves under the workbench are well fitted; if the motor drives the workbench, use the hanging basket boom to connect the elevator to the hanging basket , place the driving motor, commutator, gears, etc. in the hanging basket, and connect the lines; test whether the workbench works normally;

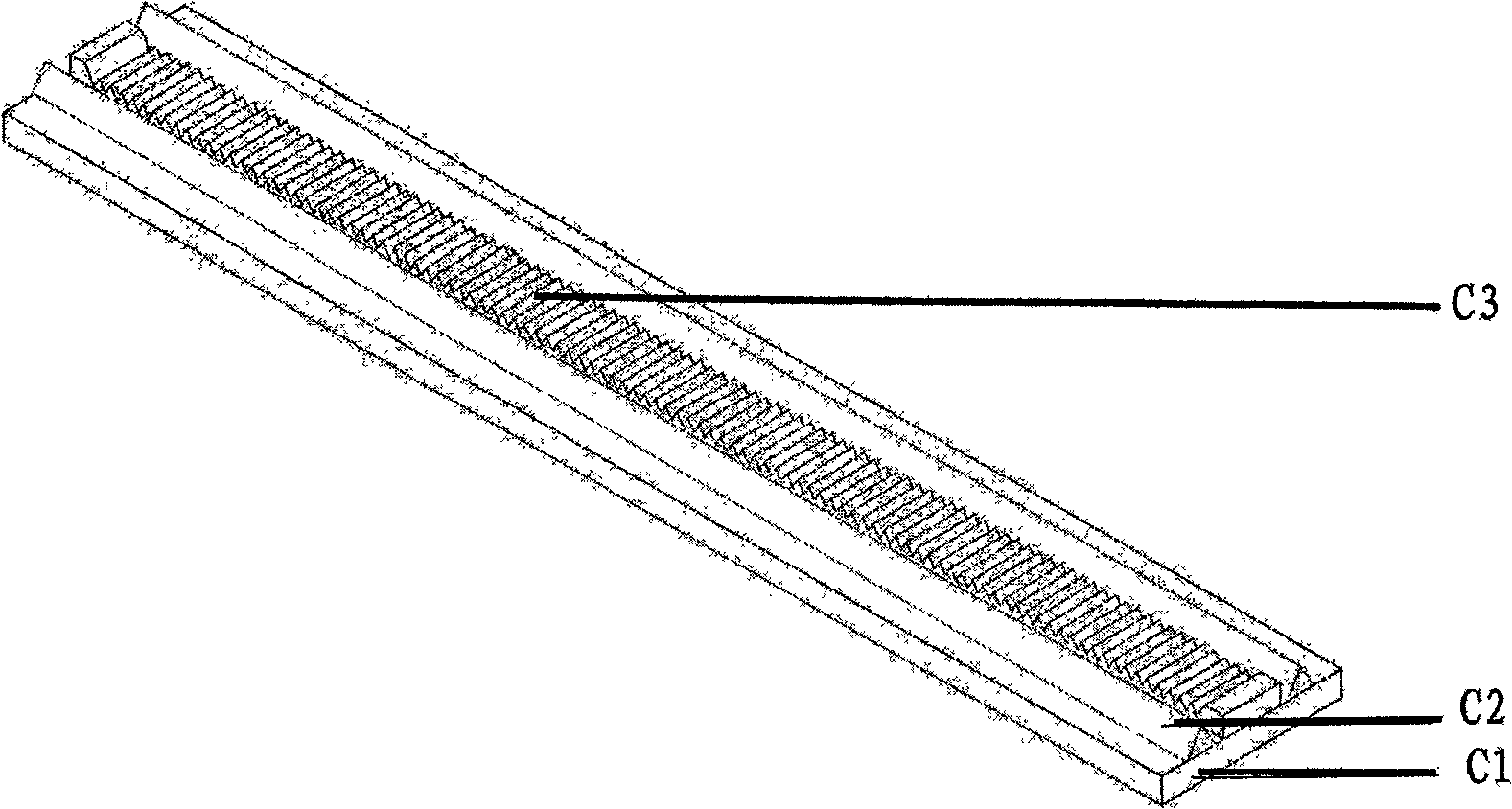

[0045] 5) Place the two sets of motor systems of the dual-purpose cutting and grinding motor system symmetrically on both sides of the workbench, adjust the relative position between the blade, the grinding stone and the workbench, and test whether the motor syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com