Semiconductor device and manufacturing method thereof

A manufacturing method, semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of increasing the amount of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

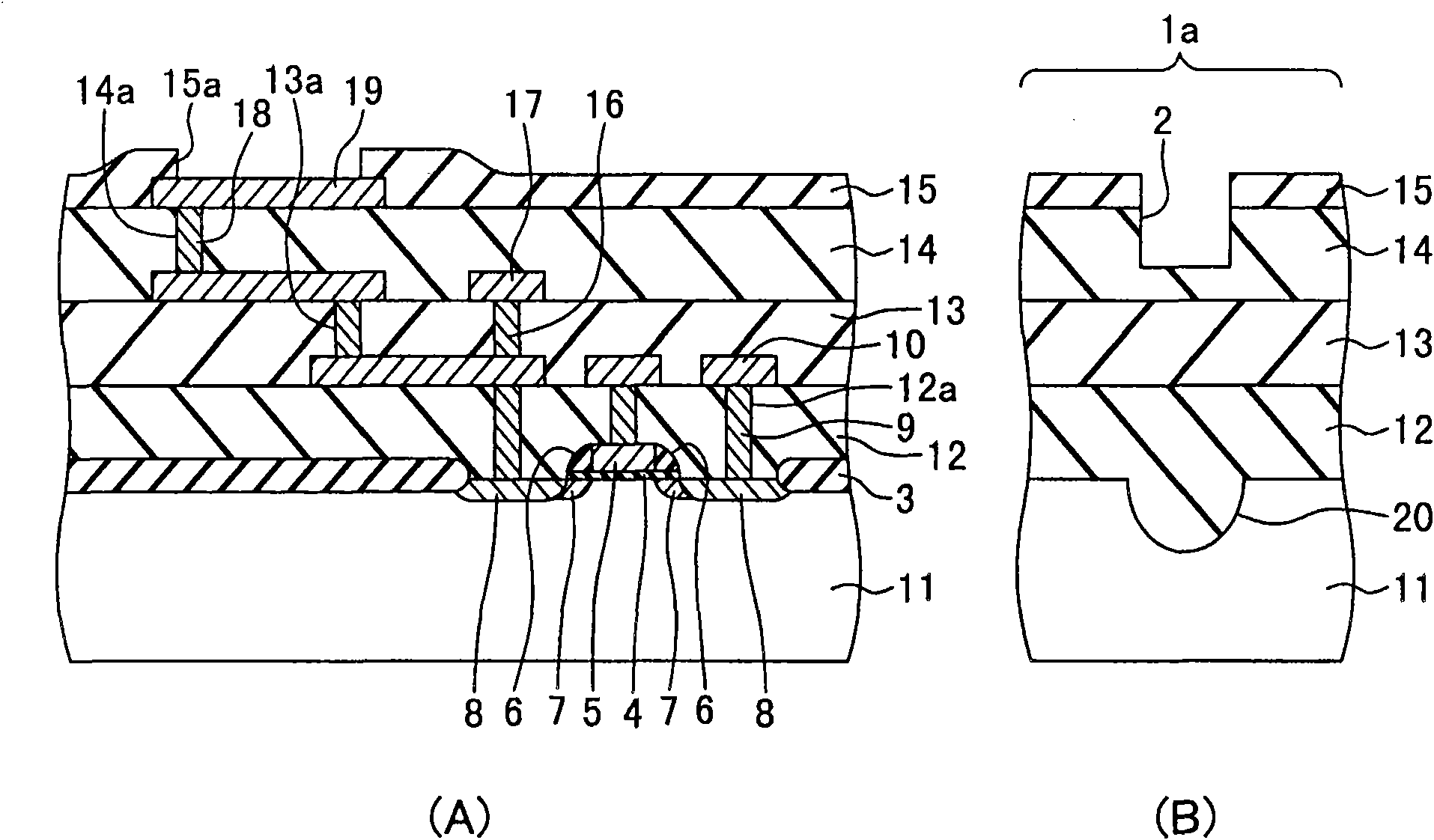

[0027] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

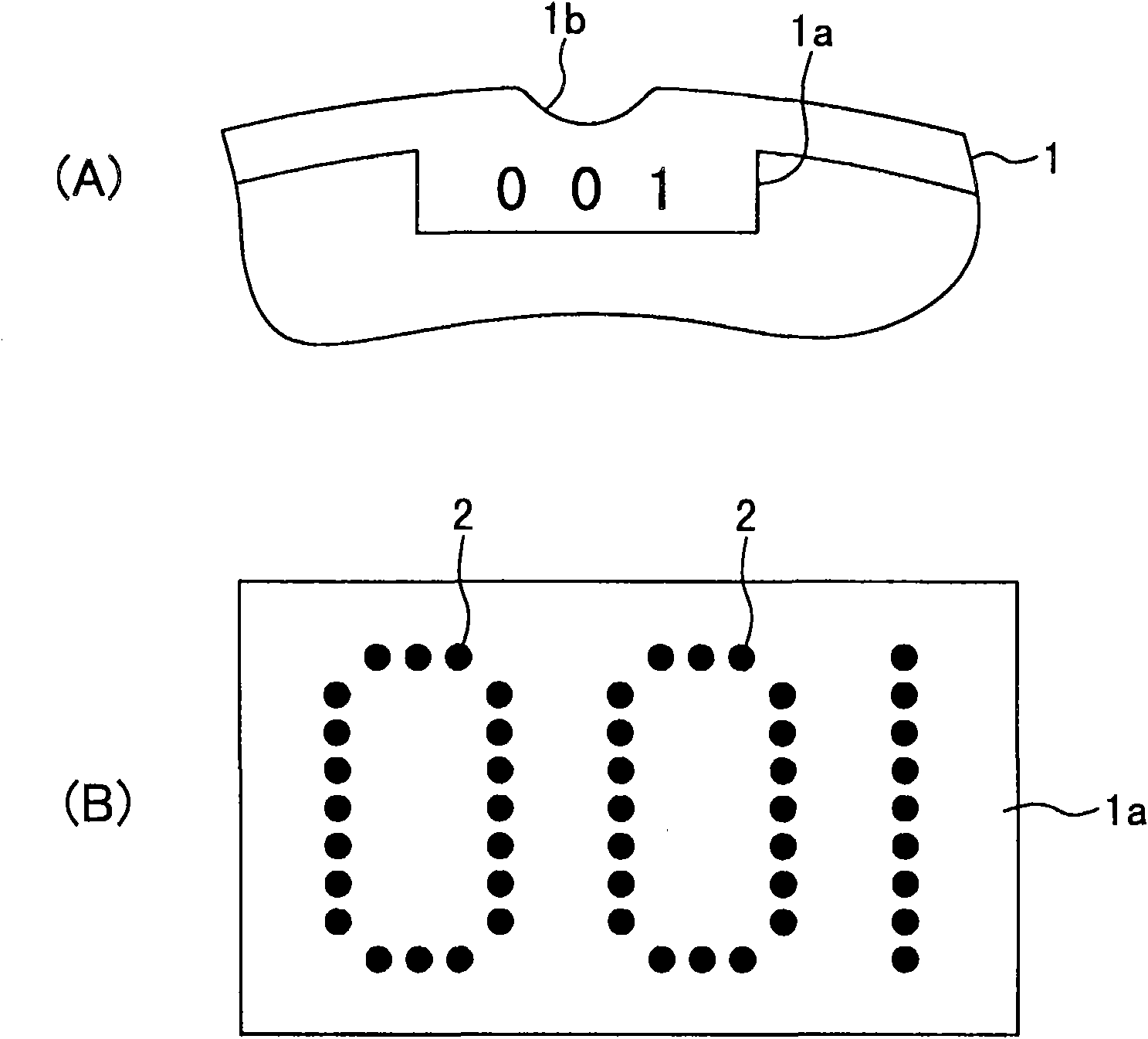

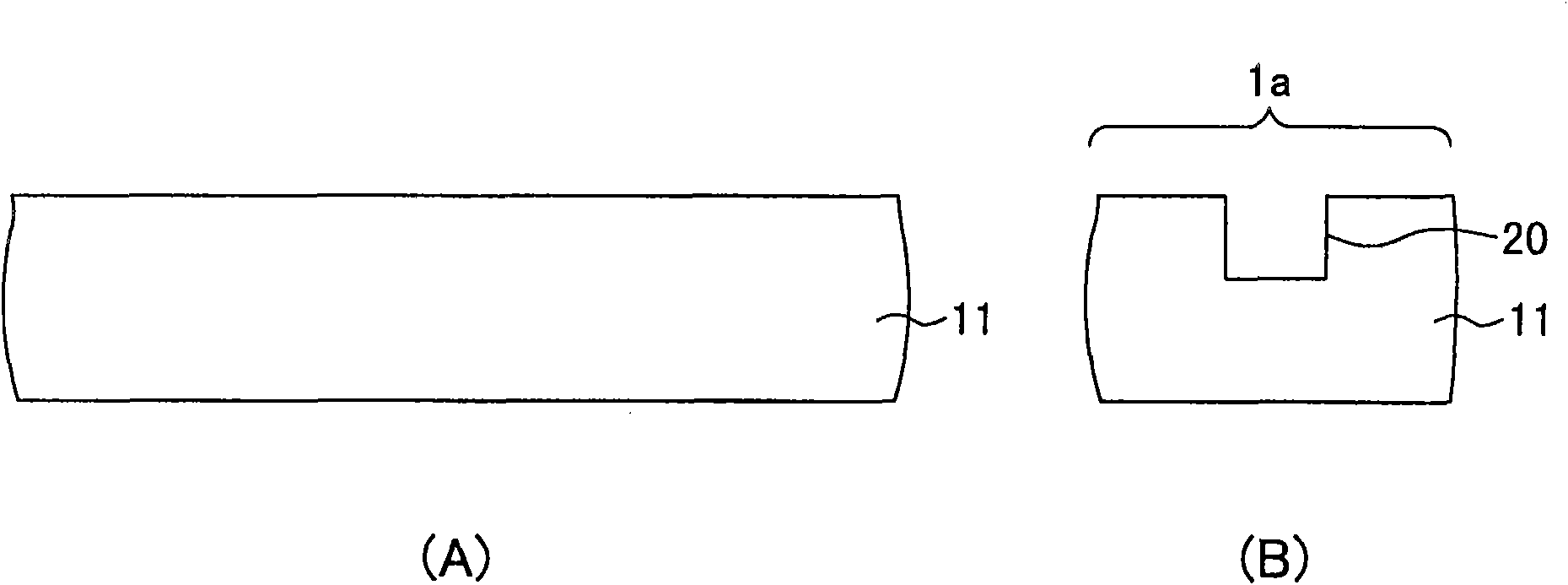

[0028] figure 1 (A), figure 1 (B) is a cross-sectional view for explaining a method of manufacturing a semiconductor device according to an embodiment of the present invention, figure 1 (A) is a cross-sectional view showing a part of a product chip region of a silicon wafer, figure 1 (B) means located in such as figure 1 (A) A cross-sectional view of a part of the print-only area near the notch of the silicon wafer shown. figure 2 (A) means if figure 1 The overall top view of the print-only area shown in (B), figure 2 (B) is for figure 2 (A) shows a magnified top view of the printed wafer ID.

[0029] First, if figure 1 (B) and figure 2 As shown in (A), the wafer ID is printed by a laser marking device on the printing-only area 1a located near the notch 1b of the silicon wafer (silicon substrate) 11 . Thus, a plurality of continuous depressions 20 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com