Method for preparing TiO2 slurry of organic carrier system

An organic carrier and system technology, applied in the field of solar cells, can solve problems such as difficult to realize, and achieve the effects of improving performance, enhancing absorption, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

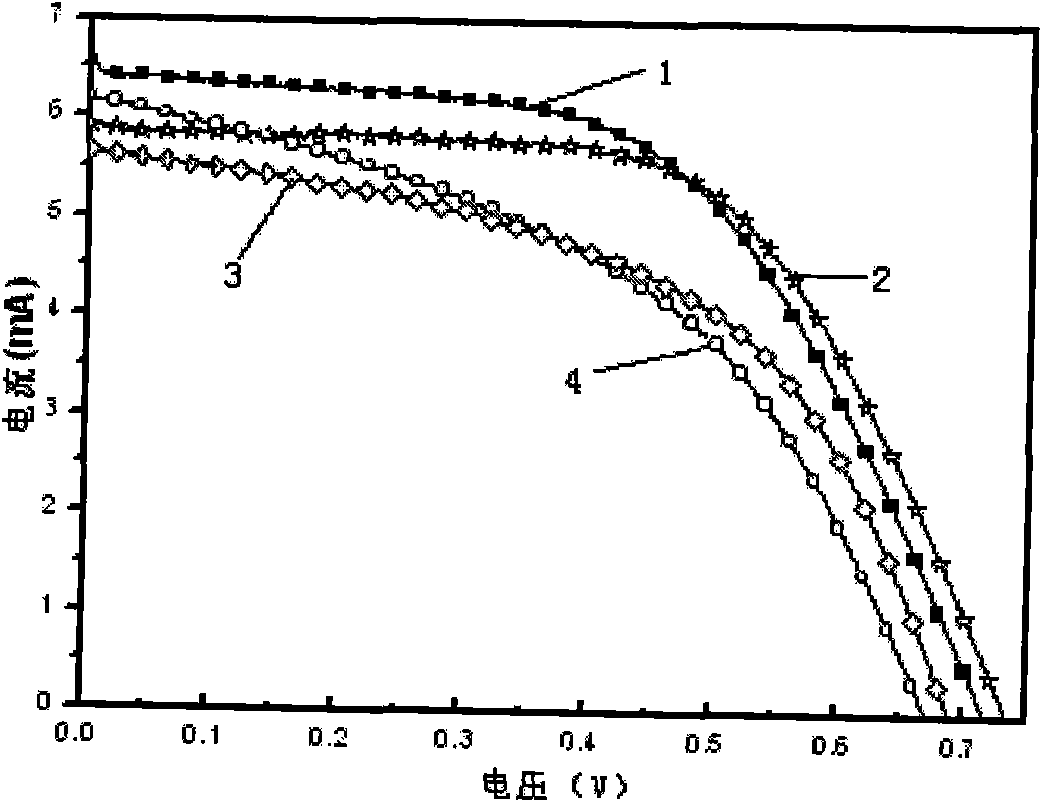

Image

Examples

Embodiment 1

[0014] A kind of TiO of organic carrier system 2 The preparation method of slurry, comprises the steps:

[0015] 1) Preparation of organic vehicle: add 1 part of ethyl cellulose to terpineol at a ratio of 1:5 by mass and number, and stir in a water bath at 80° C. for 2 hours to form an organic vehicle with a viscosity of 6.1 Kcp;

[0016] 2) TiO 2 Preparation of nano-mixed crystals: TiO with a particle size of 25nm 2 Nanocrystalline and TiO with a particle size of 100nm 2 The nanotubes are mixed in a mass ratio of 1:3;

[0017] 3) Organic carrier system nano-TiO 2 The preparation of slurry: the TiO prepared according to step 2) method 2 Nano mixed crystals are mixed with the organic carrier prepared in step 1), wherein, TiO 2 The mass fraction of nano-mixed crystals is 18 parts, and after mixing evenly, grind for 1 hour to obtain the organic carrier system nano-TiO 2 slurry.

Embodiment 2

[0019] A kind of TiO of organic carrier system 2 The preparation method of slurry, comprises the steps:

[0020] 1) Preparation of organic vehicle: add 1 part of ethyl cellulose to terpineol at a ratio of 1:7 by mass and number, and stir in a water bath at 80° C. for 2 hours to form an organic vehicle with a viscosity of 6.0 Kcp;

[0021] 2) TiO 2 Preparation of nano-mixed crystals: TiO with a particle size of 25nm 2 Nanocrystalline and TiO with a particle size of 100nm 2 The nanotubes are mixed in a mass ratio of 1:1;

[0022] 3) Organic carrier system nano-TiO 2 The preparation of slurry: the TiO prepared according to step 2) method 2 Nano mixed crystals are mixed with the organic carrier prepared in step 1), wherein, TiO 2 The mass fraction of nano-mixed crystals is 24 parts, and after mixing evenly, grind for 1 hour to obtain the organic carrier system nano-TiO 2 slurry.

Embodiment 3

[0024] A kind of TiO of organic carrier system 2 The preparation method of slurry, comprises the steps:

[0025] 1) Preparation of the organic vehicle: add 1 part of ethyl cellulose to terpineol at a ratio of 1:10 in parts by mass, and stir in a water bath at 80° C. for 2 hours to form an organic vehicle with a viscosity of 5.9 Kcp;

[0026] 2) TiO 2 Preparation of nano-mixed crystals: TiO with a particle size of 25nm 2 Nanocrystalline and TiO with a particle size of 100nm 2 The nanotubes are mixed in a mass ratio of 1:2;

[0027] 3) Organic carrier system nano-TiO 2 The preparation of slurry: the TiO prepared according to step 2) method 2 Nano mixed crystals are mixed with the organic carrier prepared in step 1), wherein, TiO 2 The mass fraction of nano-mixed crystals is 20 parts, and after mixing evenly, grind for 1 hour to obtain the organic carrier system nano-TiO 2 slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com