Detecting device for measuring difference of relative radius of curvature between sub-lenses of sphere surface spliced telescope

A technology of relative curvature and detection device, which is applied in the direction of measurement device, optical device, optical instrument test, etc., to achieve the effect of high measurement accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The detection device of the present invention will be further described in detail in the following embodiments given in conjunction with the accompanying drawings.

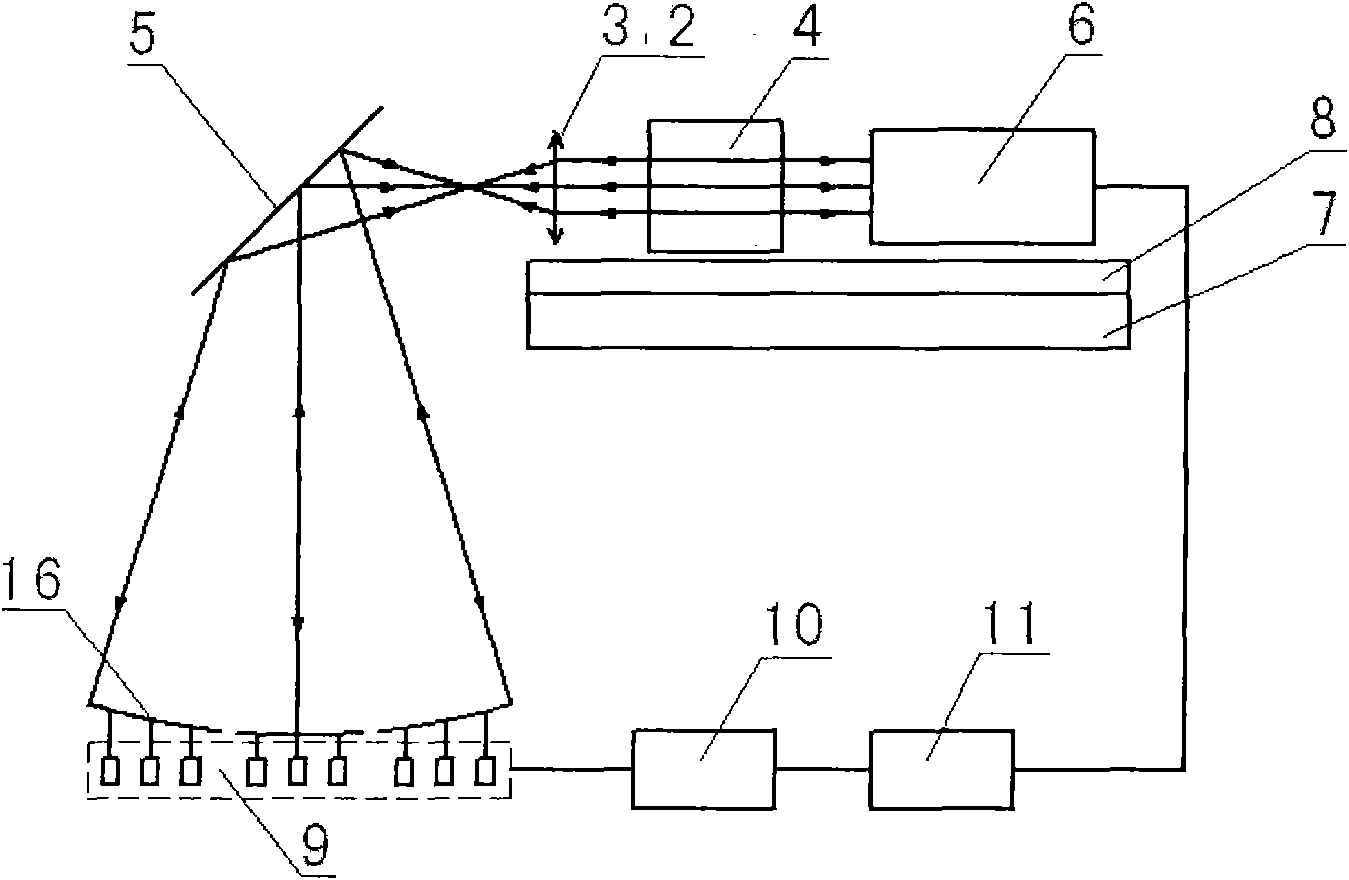

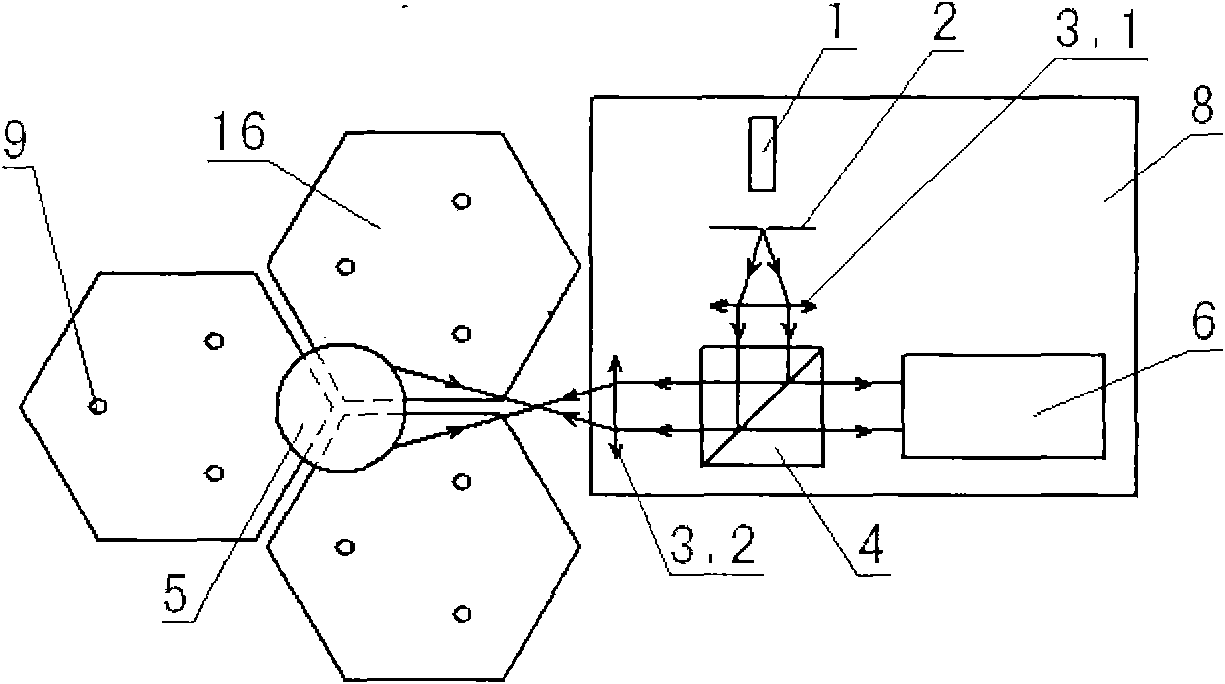

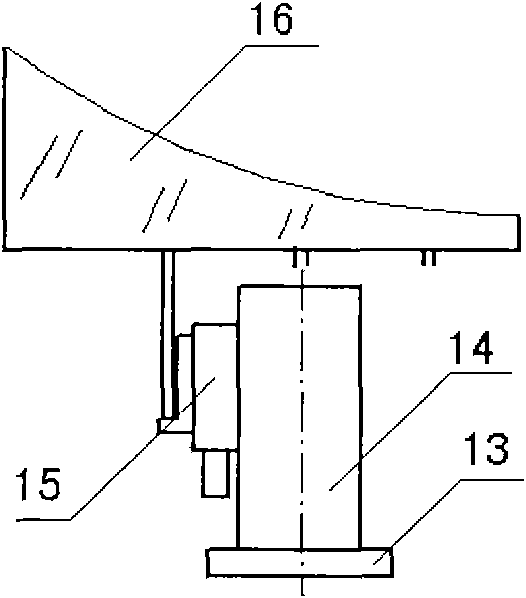

[0018] refer to figure 1 , 2 , a detection device for measuring the relative curvature radius difference between the sub-mirrors of the spherical splicing telescope, including a confocal adjustment system and a spherometer 12, the confocal adjustment system includes a laser source 1, a needle, Hole 2, two collimating lenses 3.1 and 3.2, beam splitting prism 4 and Shack-Hartmann wavefront sensor 6, plane reflector 5, micro-displacement translation stage 9, micro-displacement translation stage controller 10, computer 11; said laser source 1. After passing through the pinhole 2 and the first collimating lens 3.1, the light beam emitted from 1 passes through the second collimating lens 3.2 after being reflected by the dichroic prism 4; The Shack-Hartmann wavefront sensor 6 described above;

[0019] The plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com