Method for manufacturing ultrasonic wave embossed release paper artificial leather

A manufacturing method and technology of artificial leather, applied in chemical instruments and methods, lamination, textiles and papermaking, etc., can solve the problems of poor three-dimensional effect, single paper texture of artificial leather, etc., to save product cost, improve tensile strength, high physical and chemical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

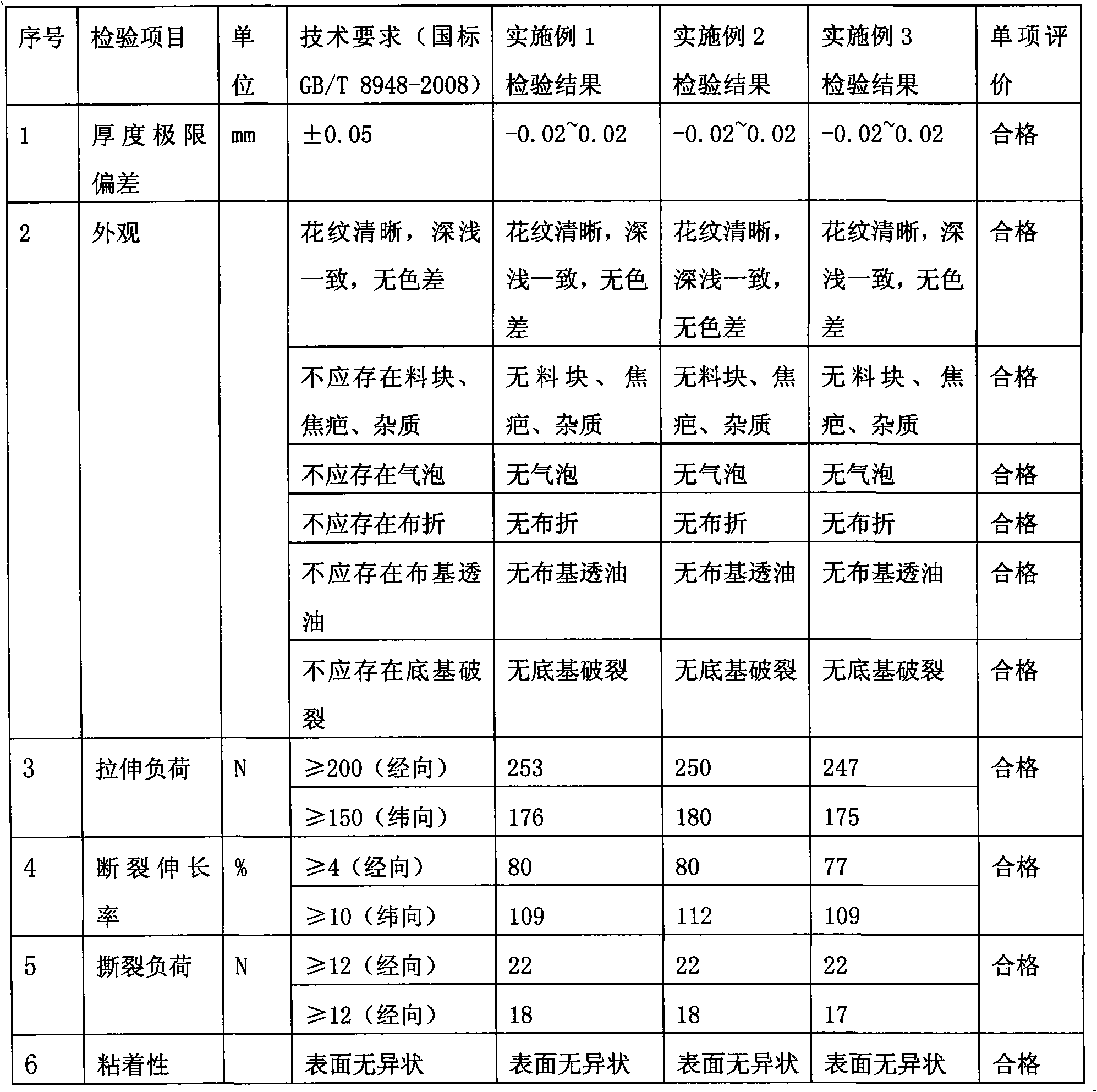

Examples

Embodiment 1

[0020] 1) Configure artificial leather bottom embryo raw materials, wherein:

[0021] Fabric formula (parts by weight): 100 parts of P440 polyvinyl chloride paste resin, 60 parts of DOP, CaCO 3 is 20 parts, potassium zinc heat stabilizer is 5 parts;

[0022] Middle layer foam layer formula (parts by weight): 100 parts of P450 polyvinyl chloride paste resin, 65 parts of DOP, CaCO 3 150 parts, potassium zinc heat stabilizer is 4 parts, AC high temperature foaming agent is 8 parts;

[0023] Primer bonding layer formula (parts by weight): 100 parts of P440 polyvinyl chloride paste resin, 50 parts of DOP, CaCO 3 5 parts, potassium zinc heat stabilizer is 2 parts;

[0024] According to the above formula, fully mix the prepared raw materials in a 30-40KW high-speed mixer until the mixture is slightly heated, and take it out for later use;

[0025] 2) Make artificial leather base embryo: apply the fabric prepared in step 1) on the release paper for artificial leather, gelatinize a...

Embodiment 2

[0028] 1) Configure artificial leather bottom embryo raw materials, wherein:

[0029] Fabric formula (parts by weight): 100 parts of P440 polyvinyl chloride paste resin, 70 parts of DOP, CaCO 3 is 30 parts, potassium zinc heat stabilizer is 8 parts;

[0030] Middle layer foam layer formula (parts by weight): 100 parts of P450 polyvinyl chloride paste resin, 80 parts of DOP, CaCO 3 250 parts, potassium zinc heat stabilizer is 8 parts, AC high temperature foaming agent is 16 parts;

[0031] Primer bonding layer formula (parts by weight): 100 parts of P440 polyvinyl chloride paste resin, 60 parts of DOP, CaCO 3 is 20 parts, potassium zinc heat stabilizer is 5 parts;

[0032] According to the above formula, fully mix the prepared raw materials in a 30-40KW high-speed mixer until the mixture is slightly heated, and take it out for later use;

[0033] 2) Making the artificial leather bottom embryo: apply the fabric prepared in step 1) on the release paper for artificial leather,...

Embodiment 3

[0036] 1) Configure artificial leather bottom embryo raw materials, wherein:

[0037] Fabric formula (parts by weight): 100 parts of P440 polyvinyl chloride paste resin, 65 parts of DOP, CaCO 3 is 25 parts, potassium zinc heat stabilizer is 7 parts;

[0038] Middle foam layer formula (parts by weight): 100 parts of P450 polyvinyl chloride paste resin, 70 parts of DOP, CaCO 3 200 parts, 6 parts of potassium zinc heat stabilizer, 12 parts of AC high temperature foaming agent;

[0039] Primer bonding layer formula (parts by weight): 100 parts of P440 polyvinyl chloride paste resin, 55 parts of DOP, CaCO 3 is 15 parts, potassium zinc heat stabilizer is 3 parts;

[0040] According to the above formula, fully mix the prepared raw materials in a 30-40KW high-speed mixer until the mixture is slightly heated, and take it out for later use;

[0041] 2) Make artificial leather base: apply the fabric prepared in step 1) on the release paper for artificial leather, gelatinize at a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com