Procuring composite layer tread rubber for tyre retreading

A tire retreading and tread rubber technology, which is applied in the field of rubber tire manufacturing, can solve the problems of increasing the overall manufacturing cost of tread rubber, and achieve the effects of reducing production costs, ensuring normal use, and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

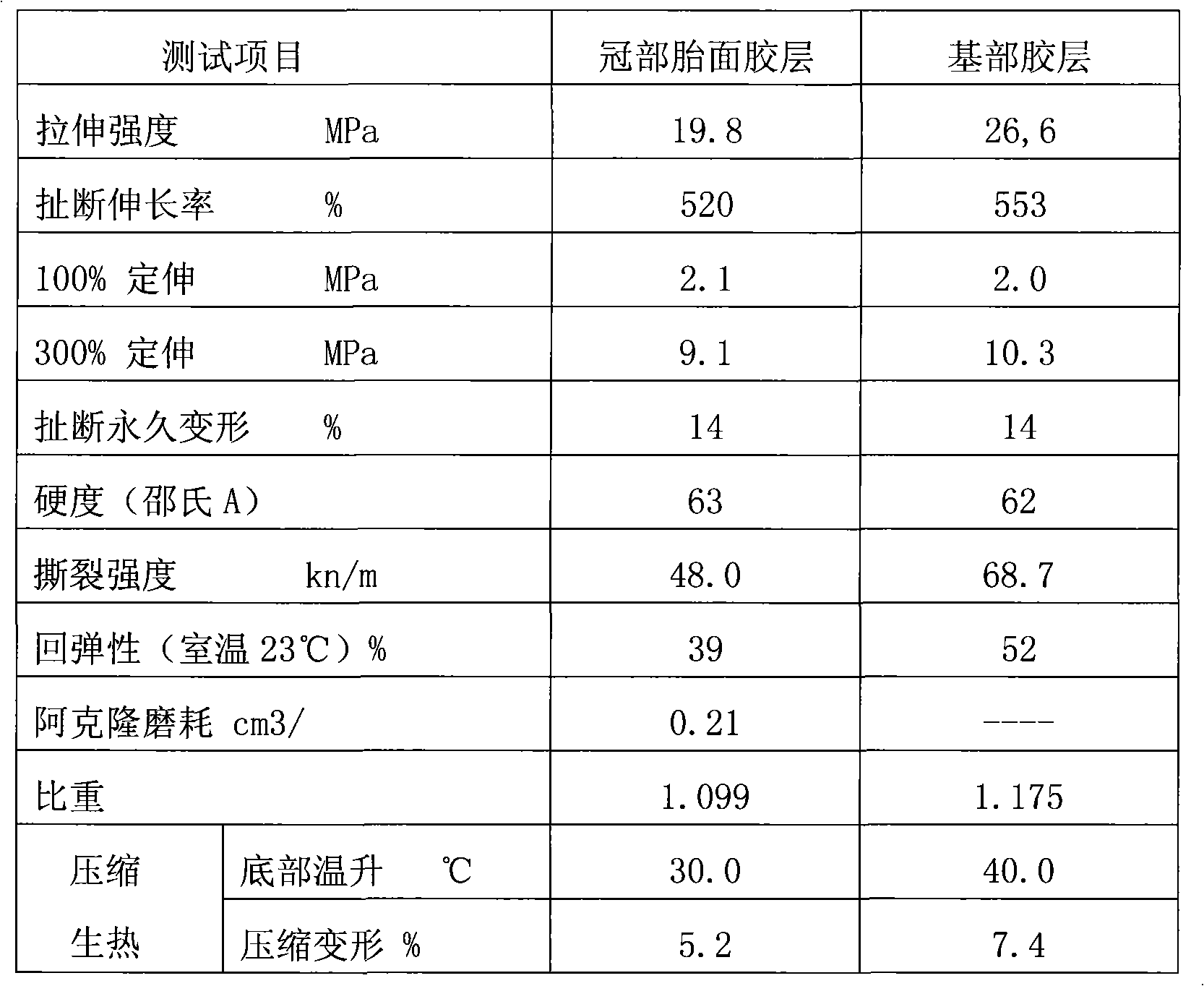

Image

Examples

Embodiment 1

[0016] Embodiment 1 provides a brand-new pre-vulcanized composite layer tread rubber according to the following proportions.

[0017] Crown tread rubber layer, 100 parts of rubber, 60 parts of high wear-resistant carbon black, 10 parts of white carbon black, 6 parts of active agent, 4 parts of anti-aging agent, 20 parts of aromatic oil, 1.5 parts of sulfur, and 1.5 parts of accelerator;

[0018] Base rubber layer, 100 parts of rubber, 30 parts of carbon black, 10 parts of white carbon black, 5 parts of active agent, 3 parts of anti-aging agent, 1.5 parts of sulfur, and 1.5 parts of accelerator.

[0019] Wherein, the outer surface of the cap tread rubber layer forms several staggered protrusions through a vulcanization process.

[0020] The crown tread rubber layer and the base rubber layer are superimposed on each other and pre-vulcanized by an annular vulcanizer. The prepared composite tread rubber is annular.

[0021] The manufacturing process of pre-vulcanized composite la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com