Method for assembling and lifting engine room section

A technology of assembly method and hoisting method, which is applied in the directions of transportation and packaging, ship building, naval vessel, etc., can solve the problems such as the thin and suspended state of the segmented structure, segmented deformation, etc., so as to avoid three-dimensional crossing operations, ensure integrity, Meet the effect of fast loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

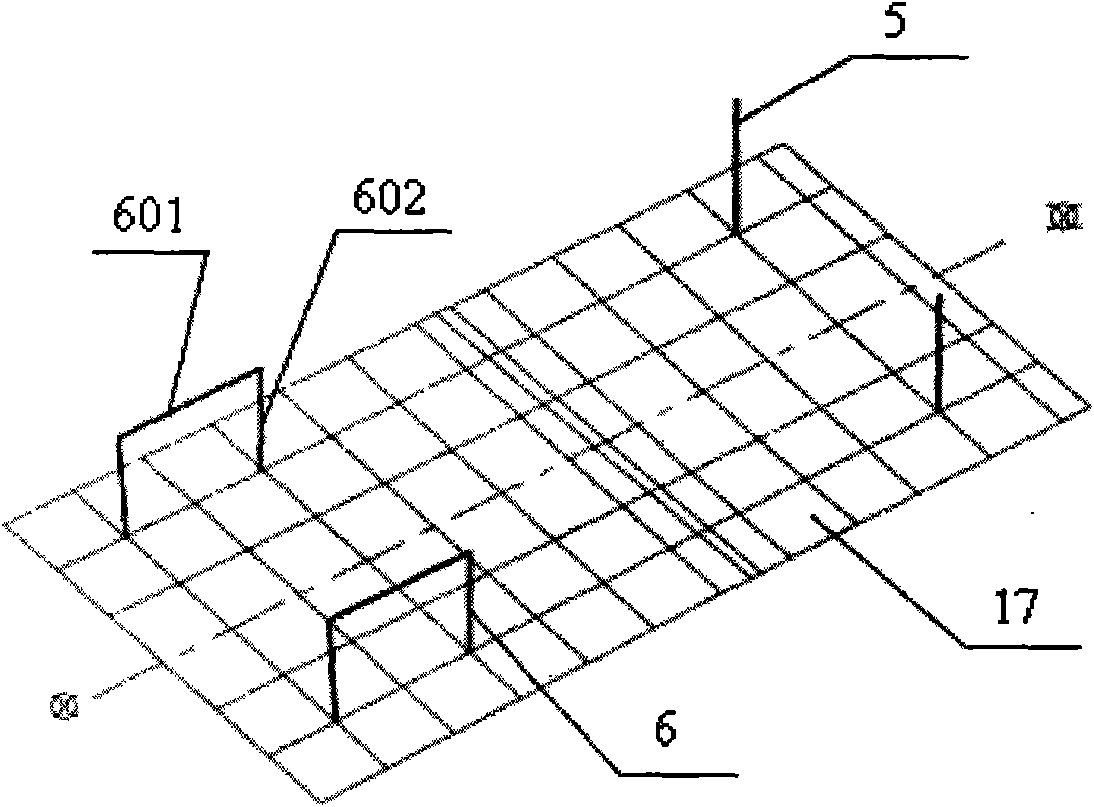

[0020] Further illustrate the present invention below in conjunction with accompanying drawing.

[0021] Such as figure 1 As shown, the general assembly method of the engine room of the present invention, the total section of the engine room includes a diaphragm cabin segment 14, a suspended deck platform segment 13, an intermediate deck platform segment 12 and an upper deck platform segment 11, and the intermediate deck platform In the middle of the segment 12 and the upper deck platform segment 11, an engine hatch 16 is provided, which includes the following assembly steps:

[0022] (1) Reinforcement treatment of each segment: The seam allowance of the original big closing cut is cut off during segmental manufacturing, so that the left and right sides form a segment, and the deck and frame are required to be completely welded. After the manufacture of each segmented tire frame is completed, four 30# channel steels are preset and arranged around. After the planking of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com