Device and method for quick positioning of prefabricated floor slabs

A floor-slab and fast technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of high-altitude operation, such as many hidden dangers, poor positioning accuracy, low operation efficiency, etc., to reduce labor consumption and avoid introduction , the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

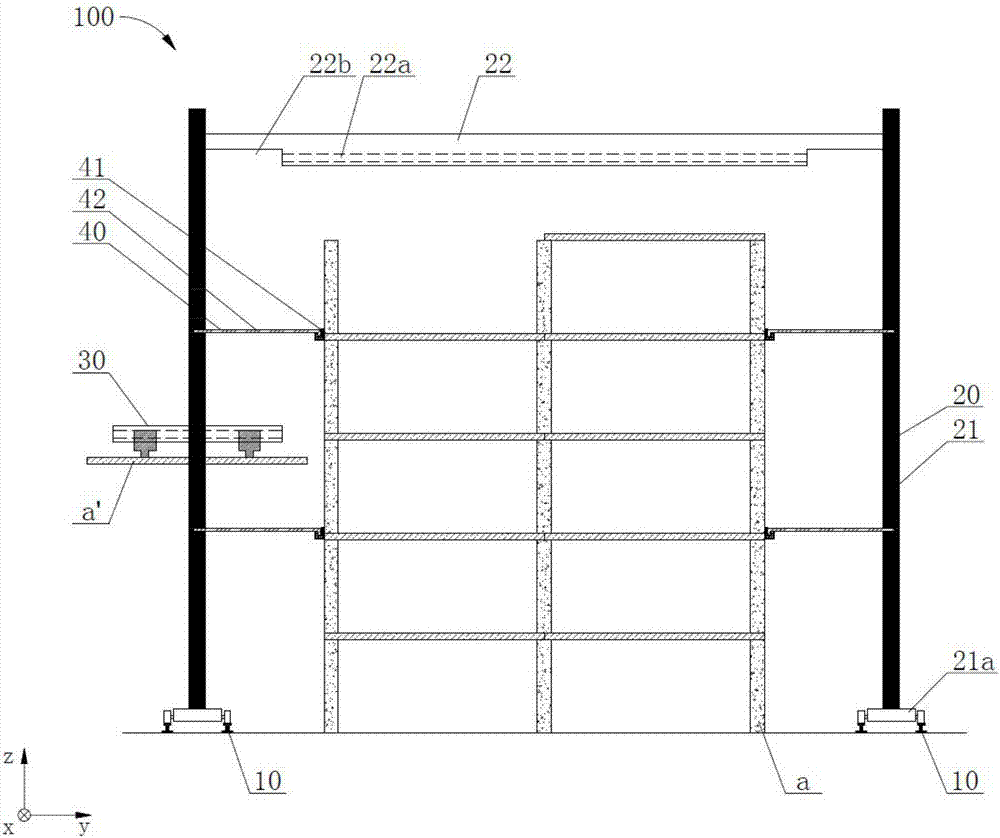

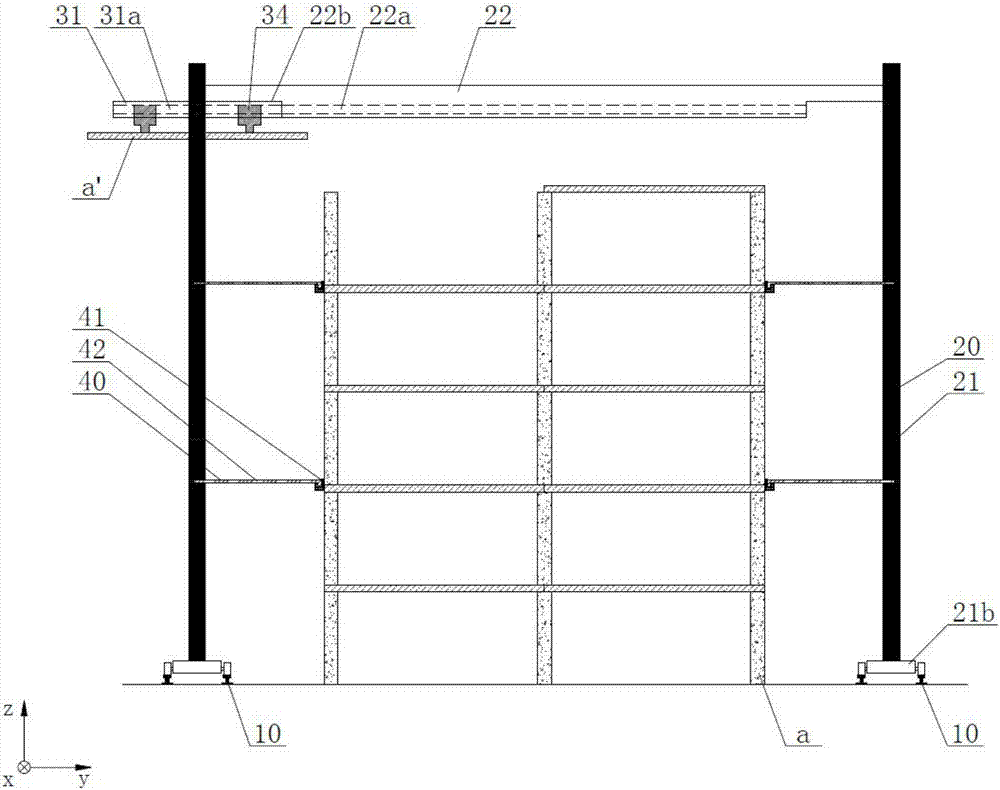

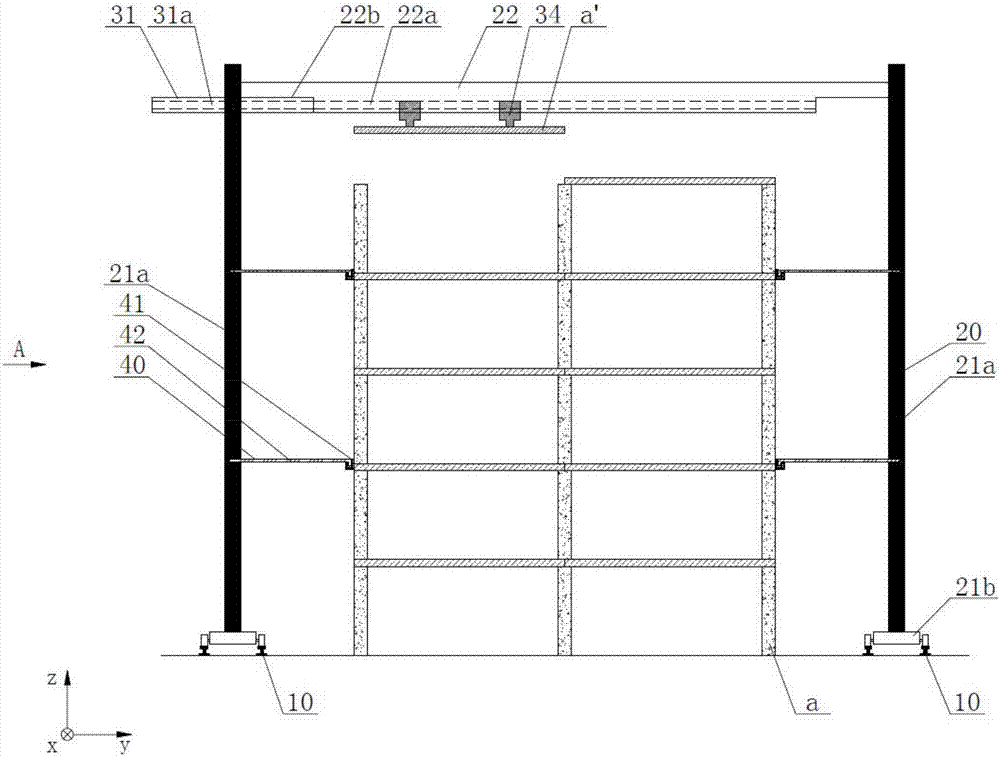

[0027] Example 1: Combining Figure 1 to Figure 6Explain that the quick positioning device 100 for prefabricated floor slabs of the present invention, in order to clarify the direction relationship, sets the xyz Cartesian coordinate system with the z-axis direction as the height extension direction of the prefabricated building frame a as required. It includes a pair of ground tracks 10 arranged on both sides of the prefabricated building frame a; at least one U-shaped track frame 20 that can slide along the ground track 10; A pair of vertical guide rails 21, a crossbeam 22 in place located above the prefabricated building frame a and connected between the pair of vertical guide rails 21; It is used for hoisting the climbing frame 30 of the horizontal pushing guide rail crossbeam of the prefabricated floor slab a'. The above-mentioned horizontal pushing guide rail crossbeam climbing frame 30 is connected with the power control system (not shown in the figure), and is used to ...

Embodiment 2

[0037] Embodiment 2: Combination Figure 1 to Figure 6 Illustrate the quick positioning method of prefabricated floor slabs of the present invention, the specific steps are as follows:

[0038] S101: if figure 1 As shown, assemble the prefabricated floor quick positioning device 100 so that it is enclosed on the top and both sides of the prefabricated building frame a;

[0039] S102: At the initial position, hang the prefabricated floor slab a' on the climbing frame 30 of the horizontal push guide rail crossbeam; figure 2 As shown, the horizontal push guide rail crossbeam climbing frame 30 is lifted upwards along the vertical guide rail 21 to the same height as the in place crossbeam 22 through the power control system; image 3 As shown, after the frame body 31 of the horizontal push guide rail beam climbing frame 30 is docked with the in-place beam 22, the guide rail beam 34 is controlled to move horizontally along the in-place beam 22, and the prefabricated floor a' is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com