Automatic adjustment positioning device in a six-dimensional space

A technology of automatic adjustment and positioning device, applied in control/adjustment system, position/direction control, non-electric variable control and other directions, can solve the problems of complex adjustment mechanism, high processing cost, cumbersome adjustment, etc., and achieve simplified mechanism and processing cost. Simple and reliable effect of reduction and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

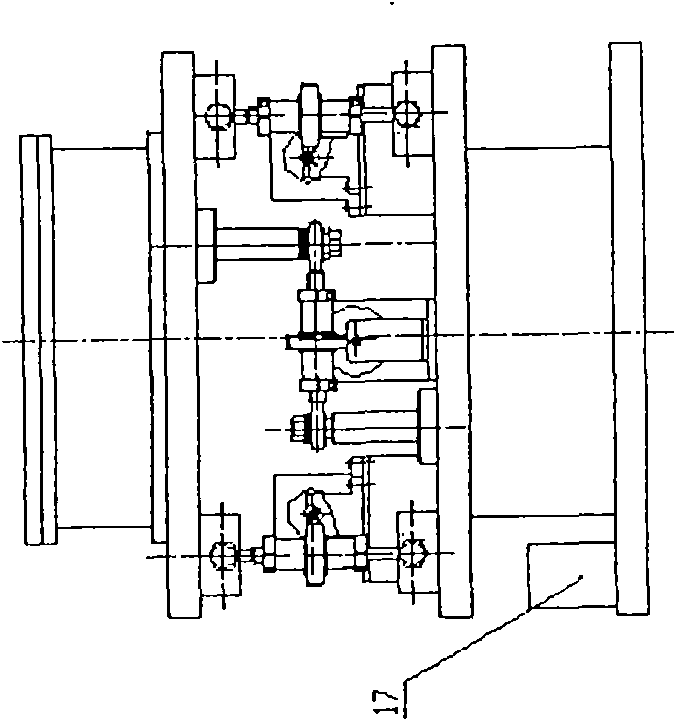

[0015] according to figure 1 , figure 2 , image 3 , Figure 4 , to further illustrate the six-dimensional automatic adjustment and positioning device of the present invention for the spatial positioning of the vacuum mirror box in the synchrotron radiation beamline.

[0016] The components shown in the figure: screw sleeve 1, A screw rod 2, B screw rod 3, support 4, joint bearing 5, bolt 6, screw 7, washer 8, worm screw 10, chrome-plated after processing with 45 steel; worm gear 9, lock nut 12 is processed with bronze; Bearing seat 13, movable plate 19, fixed bracket 20, are made with No. 45; Support box body 21 stainless steel is made; Bearing 11, shaft coupling 14, motor frame 15, servo motor 16, Power supply 17, computer 18 are outsourced.

[0017] Debugging method steps: Take the spatial positioning of the vacuum mirror box in the synchrotron radiation beamline as an example:

[0018] First of all, when assembling and adjusting, the assembled and adjusted spiral str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com