Single bushing-type MC nylon wheel

A technology of nylon wheels and sleeves, which is applied in the direction of instruments, control components, mechanical control devices, etc., can solve problems such as bearing shaking, affecting transmission accuracy and service life, slipping, etc., and achieve the effect of improving the operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

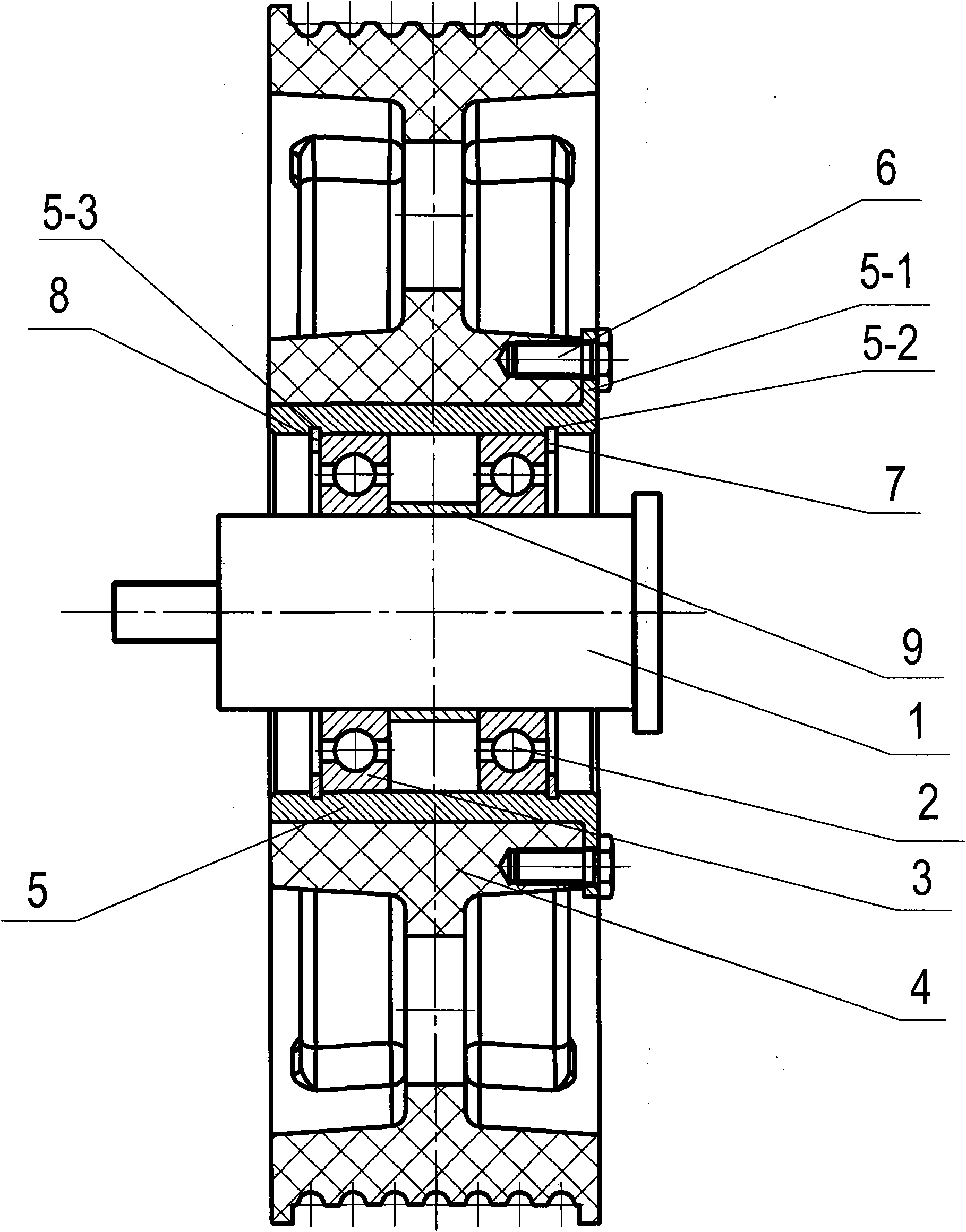

[0012] Such as figure 1 As shown, two bearings 2, 3 are placed outside the axle 1 made of rigid material.

[0013] A rigid insert 5 whose outer diameter is not greater than the inner circle of the wheel body 4 is arranged on the inner wall of the wheel body 4 made of MC nylon. An outer end of the insert 5 is provided with a flange side 5-1, and the flange side 5-1 is fixedly connected to one end of the wheel body 4 through a bolt 6.

[0014] Annular grooves 5-2, 5-3 are provided on the inner wall of the inserting sleeve 5 respectively, and retaining rings 7, 8 are respectively supported in the annular grooves 5-2, 5-3, and the two bearings 2, The two outer ends of 3 are respectively limited between the circlips 7 and 8, and a bush 9 is arranged between the two bearings 2 and 3, and the bush 9 is sleeved outside the axle 1.

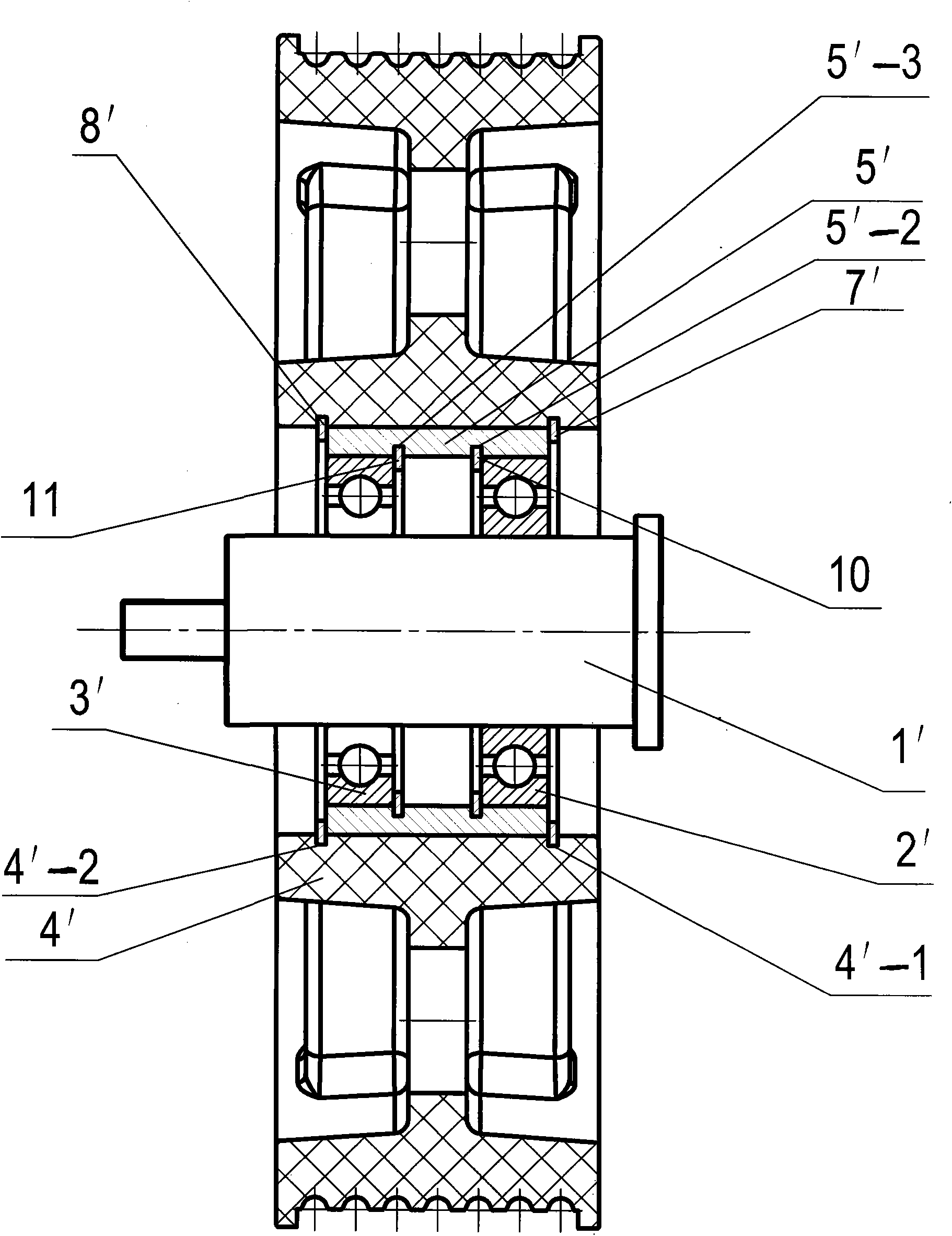

[0015] Such as figure 2 As shown, two bearings 2', 3' are placed outside the axle 1' made of rigid material.

[0016] In the inner wall of the wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com