Method for measuring object deformation in real time

A real-time measurement and object technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of expensive equipment, insufficient sensitivity and accuracy, and large impact, and achieve the effect of improving the overall measurement accuracy and lighting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

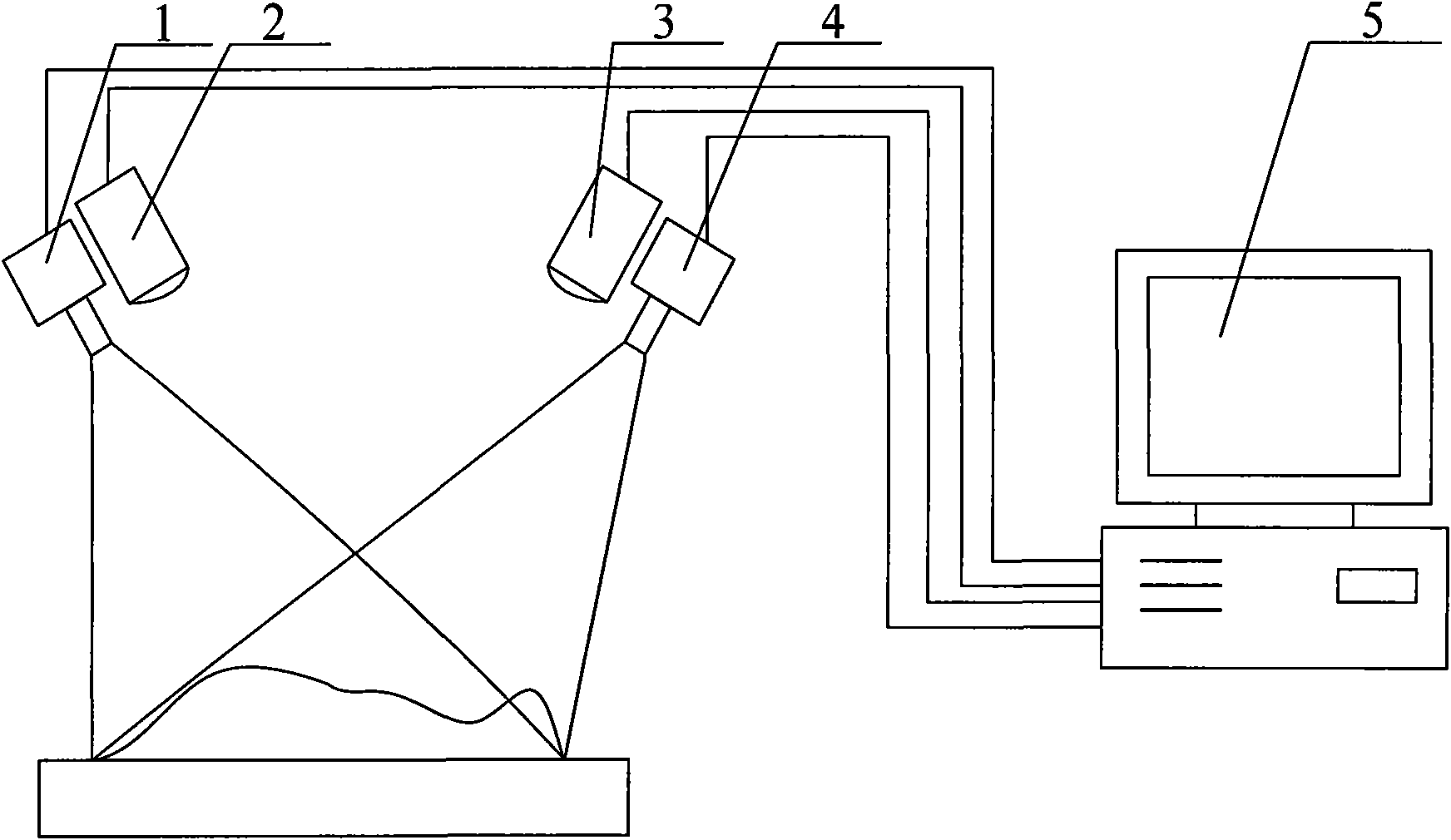

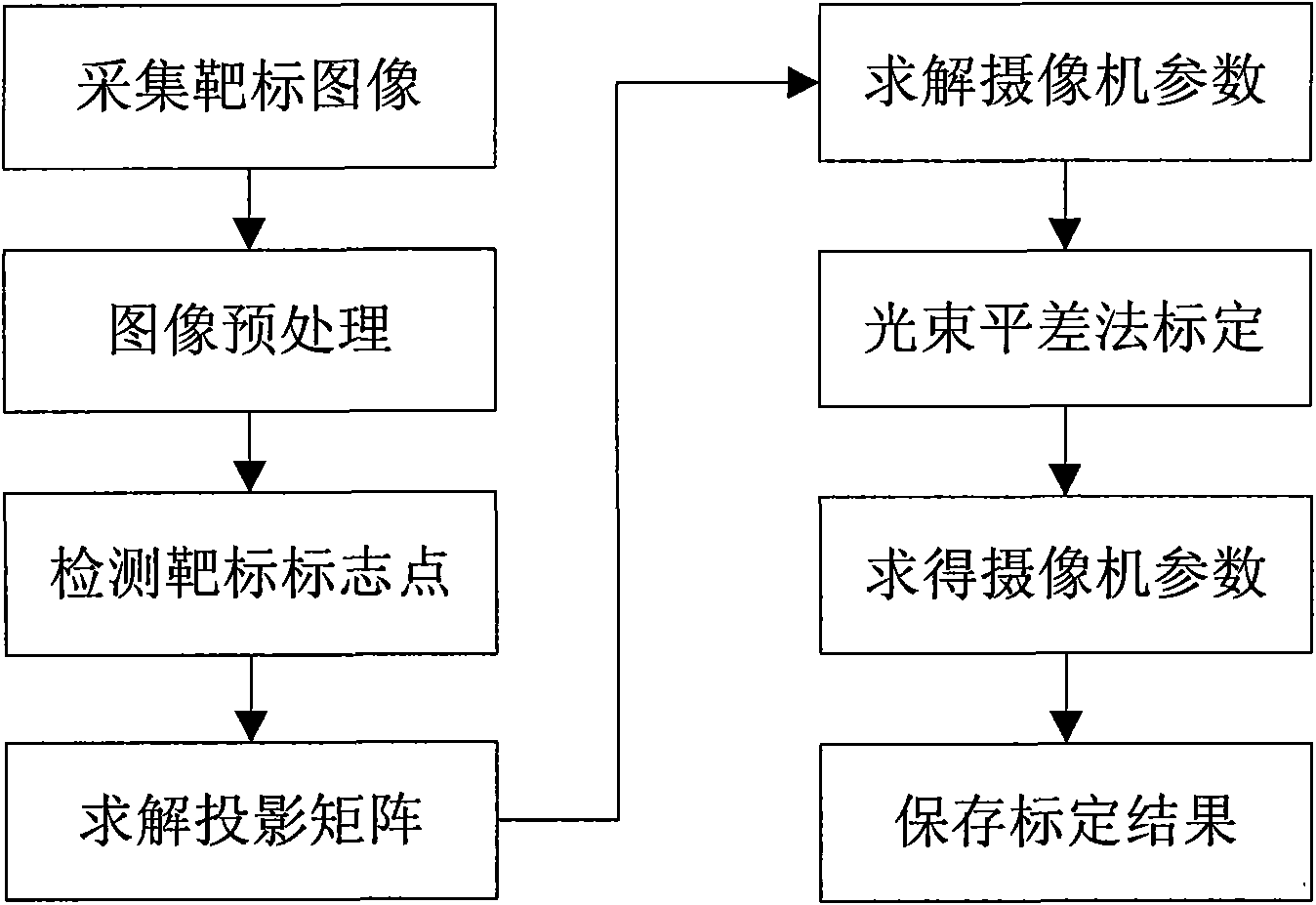

[0041] The present invention proposes a real-time measurement method for object deformation, such as figure 1 shown. measurement system such as figure 2 As shown, it is composed of CCD cameras 1, 4, LED lighting lamps 2, 3, computer 5 and so on. Computer 5 is a Pentium(R) 4CPU, 2.66GHz, with a 1394 image acquisition card, and supports dual monitor output. The software is independently developed based on Visual C++6.0 platform. The CCD adopts the A500 series camera from Basler in Germany. The camera adopts Camera Link output, external synchronization or internal autonomous operation, and the frame rate can reach 500fps when the resolution is 1280*1024, and the camera can be programmed and controlled.

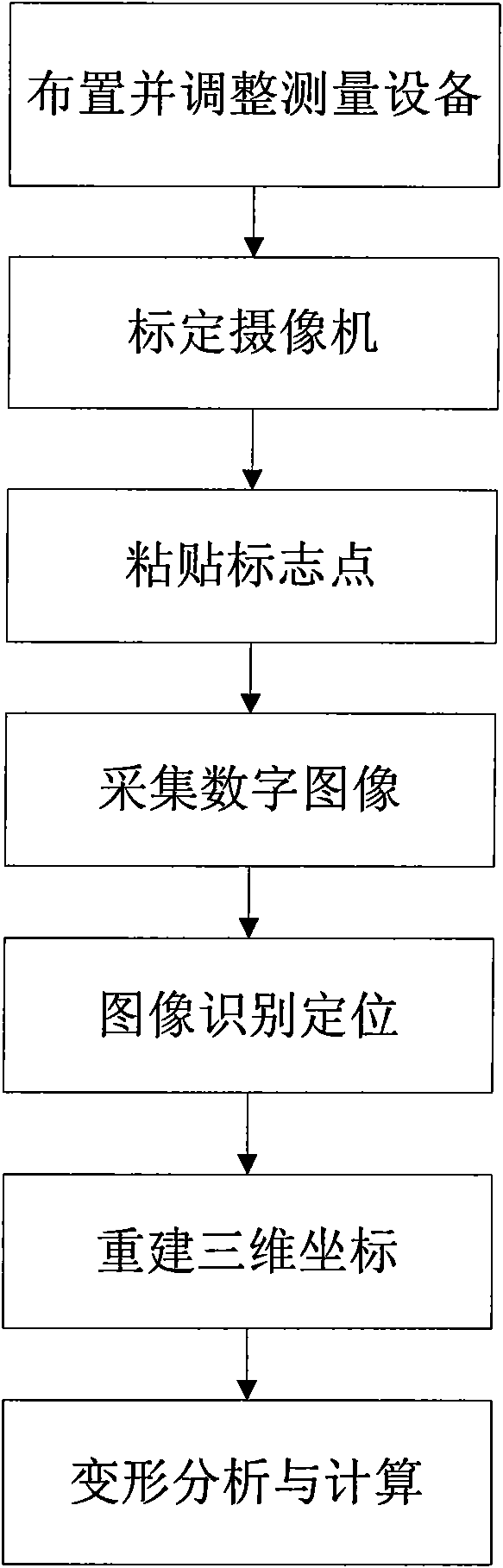

[0042] figure 1 The overall steps of the inventive method shown are as follows:

[0043] (1) Arrange and adjust the measuring equipment: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com