Micron bubble-generating device and special cyclone thereof

A technology of micro-bubbles and cyclones, which is applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of difficult processing, high material strength requirements, easy clogging of micropores, etc., to avoid Large energy loss, low equipment cost and energy consumption, and the effect of improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

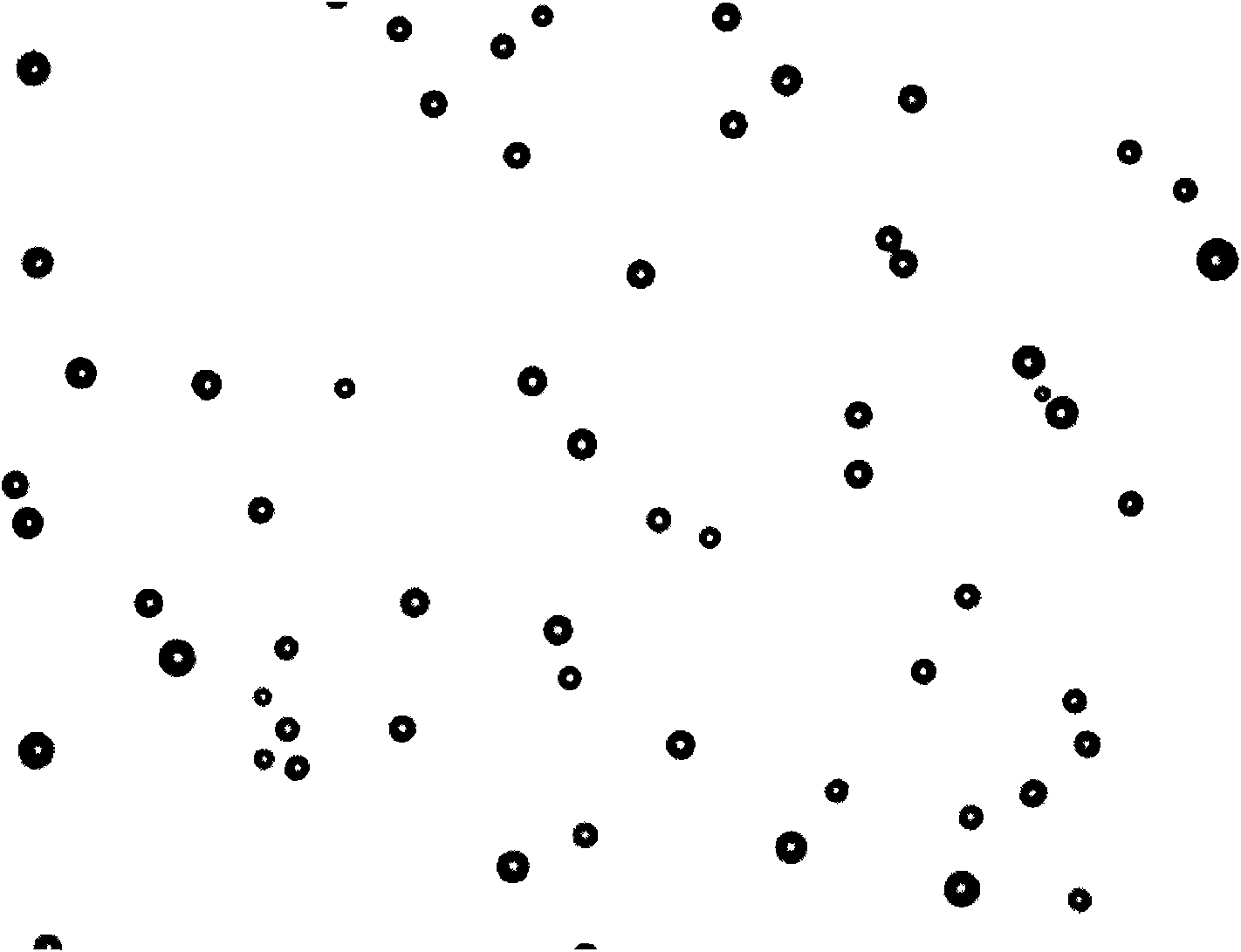

[0040] Embodiment 1, utilize the particle diameter of the microbubble that described device produces

[0041] 1. Micro bubble generating device

[0042] 1. Cyclone

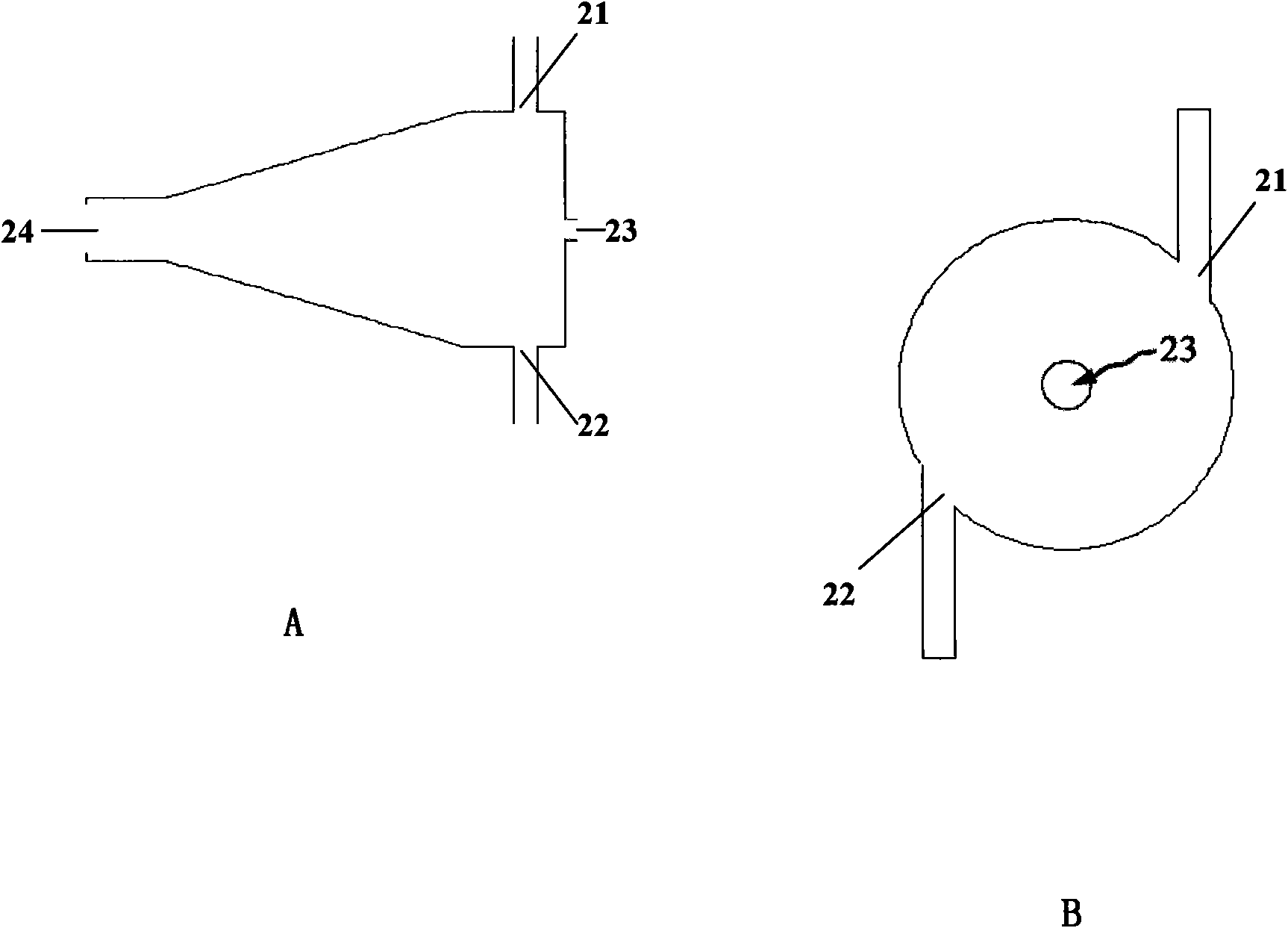

[0043] The structure of the cyclone is as figure 1 shown.

[0044] The above-mentioned cyclone is made of plastic.

[0045] In the cyclone, the height of the frustum-shaped cavity is 75mm, the diameter of the upper bottom is 16mm, the diameter of the lower bottom is 60mm, and the height of the cylindrical cavity is 25mm; the volume of the inner cavity of the cyclone is about 170mL; the through hole The inner diameter of 21 and 22 is 10 mm; the inner diameter of through hole 23 is 6 mm; the inner diameter of through hole 24 is 16 mm.

[0046] Pipes are connected to the through holes 21 and 22, and the inner diameter of the pipes is 10 mm. A pipe is connected to the through hole 23, and the inner diameter of the pipe is 6mm.

[0047] 2. Micro bubble generating device

[0048] The structure of the micro-bubble...

Embodiment 2

[0069] Embodiment 2, the mensuration of the oxygen mass transfer performance of micro-bubble generating device

[0070] The device of the present invention is tested by using a general test method for oxygen mass transfer performance in the field of water treatment. The indicators of oxygen mass transfer performance include overall mass transfer coefficient, oxygen charging capacity and oxygen transfer efficiency.

[0071] Overall mass transfer coefficient K L a is calculated according to the following formula:

[0072] dC dt = K L a ( C * - C )

[0073] In the formula, C is the measured dissolved oxygen concentration, C* is the saturated dissolved oxygen concentration, and t is the reaction time.

[0074] Oxygenation capacity R=K L a×C *

[0075] Oxygen transfer efficien...

Embodiment 3

[0099] Embodiment 3, the influence of temperature on the mass transfer performance of device

[0100] 1. Micro bubble generating device

[0101] Same as Step 1 of Example 1.

[0102] Insert a thermometer in the reactor.

[0103] 2. Micro bubbles are generated under different temperature conditions

[0104] Reactor 1 was filled with water to 15L, and 70mg CoCl was weighed 2 and 0.9g Na 2 SO 3 Add water to remove dissolved oxygen; turn on the water pump after the reading of the dissolved oxygen meter is zero, and adjust the temperature, liquid flow and gas flow of the water in the reactor, as follows:

[0105] Test One: Q L =65,Q g =26,T 0 = 22.5°C;

[0106] Test Two: Q L =65,Q g =26,T 0 = 30.1°C;

[0107] Trial Three: Q L = 45, Q g =20,T 0 = 22.5°C;

[0108] Test Four: Q L = 45, Q g =20,T 0 = 30.8°C;

[0109] Test Five: Q L =30,Q g =9,T 0 = 22.5°C;

[0110] Test Six: Q L =30,Q g =9,T 0 = 30.8°C;

[0111] Among them, Q L Represents liquid flow; Q g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com