Head lamp for heavy automobile

A technology for heavy-duty vehicles and headlights, applied to vehicle parts, optical signals, signal devices, etc., can solve the problems of inconvenient maintenance work, achieve the effect of convenient maintenance, reduce maintenance steps, and reduce maintenance difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The headlight main body 2 of the present invention sinks into the headlight mounting hole 10 on the bumper 6 that matches the shape of the headlight main body 2, so that the lampshade outer surface of the headlight main body 2 It coincides with the curved surface of the outer surface of the bumper 6 described above.

[0034] Such as image 3 , Figure 5 and Figure 6 As shown, the headlight main body 2 of the headlight 7 matches the curved surface of the outer surface of the bumper 6, the appearance is beautiful, and the stability of the lamp is better.

Embodiment 2

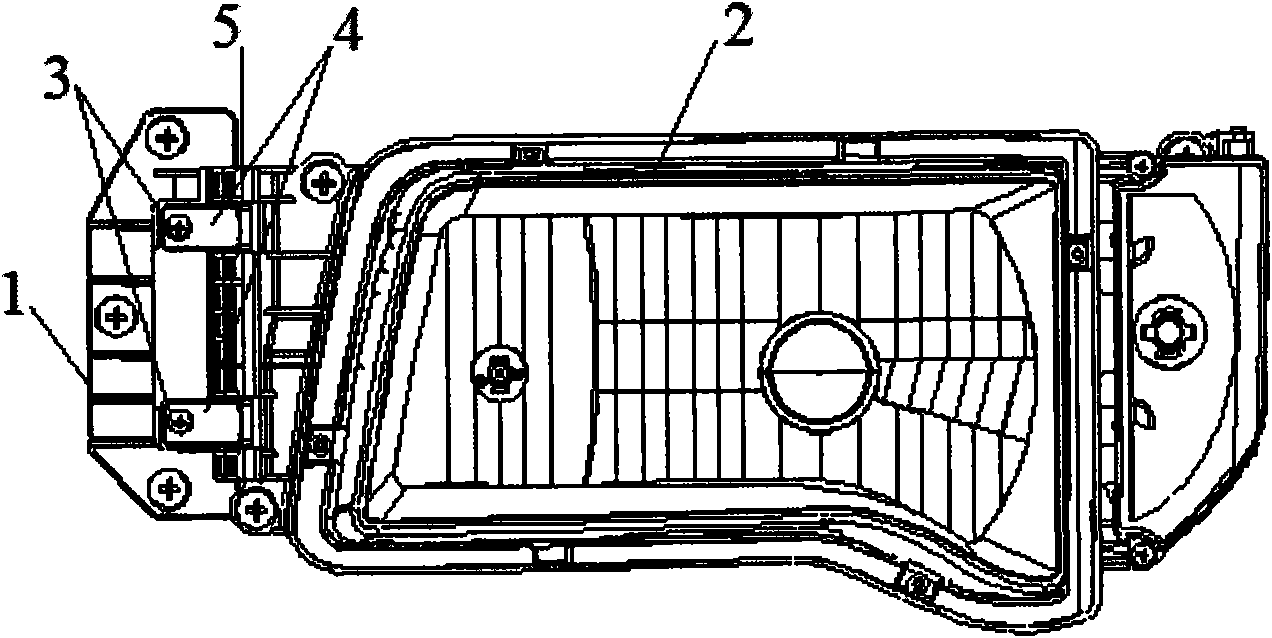

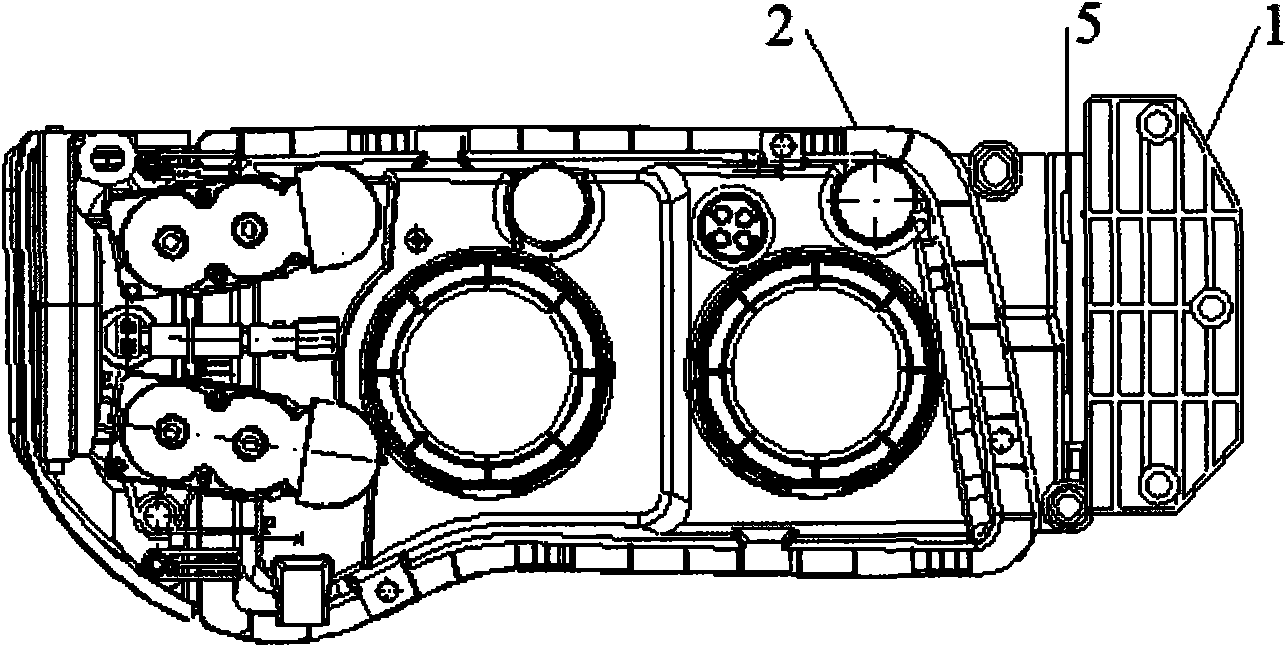

[0036] as shown in the picture image 3 and Figure 4 Shown, the structure that rotating shaft 5 of the present invention is connected is:

[0037] On the bumper 6, a headlight rotating support seat 1 is provided, and a rotating shaft installation groove 9 matching the shape of the rotating shaft 5 is arranged on the described headlight rotating supporting seat 1, and the rotating shaft 5 is connected to the front The lamp main body 2 is connected as a whole, the head lamp main body 2 is installed in the rotating shaft installation groove 9 through the rotating shaft 5, and the rotating shaft 5 is fixed in the rotating shaft installation groove 9 through the rotating shaft pressing piece 4. in slot 9.

[0038] The headlight main body 2 is connected with the automobile bumper 6 through the headlight rotating support base 1 . The rotating shaft 5 rotates in the rotating shaft installation groove 9 .

[0039] In the present invention, the headlight is designed as a rotatable ...

Embodiment 3

[0041] The headlight rotating support base 1 of the present invention is arranged in the headlight installation hole 10 . Such setting makes the appearance of the headlight 7 beautiful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com