Regulator of feeding device of forged part forming machine

A technology of feeding device and forming machine, applied in the field of adjusters, which can solve the problems of large load and action resistance, easy loosening of assembly structure, large swing distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

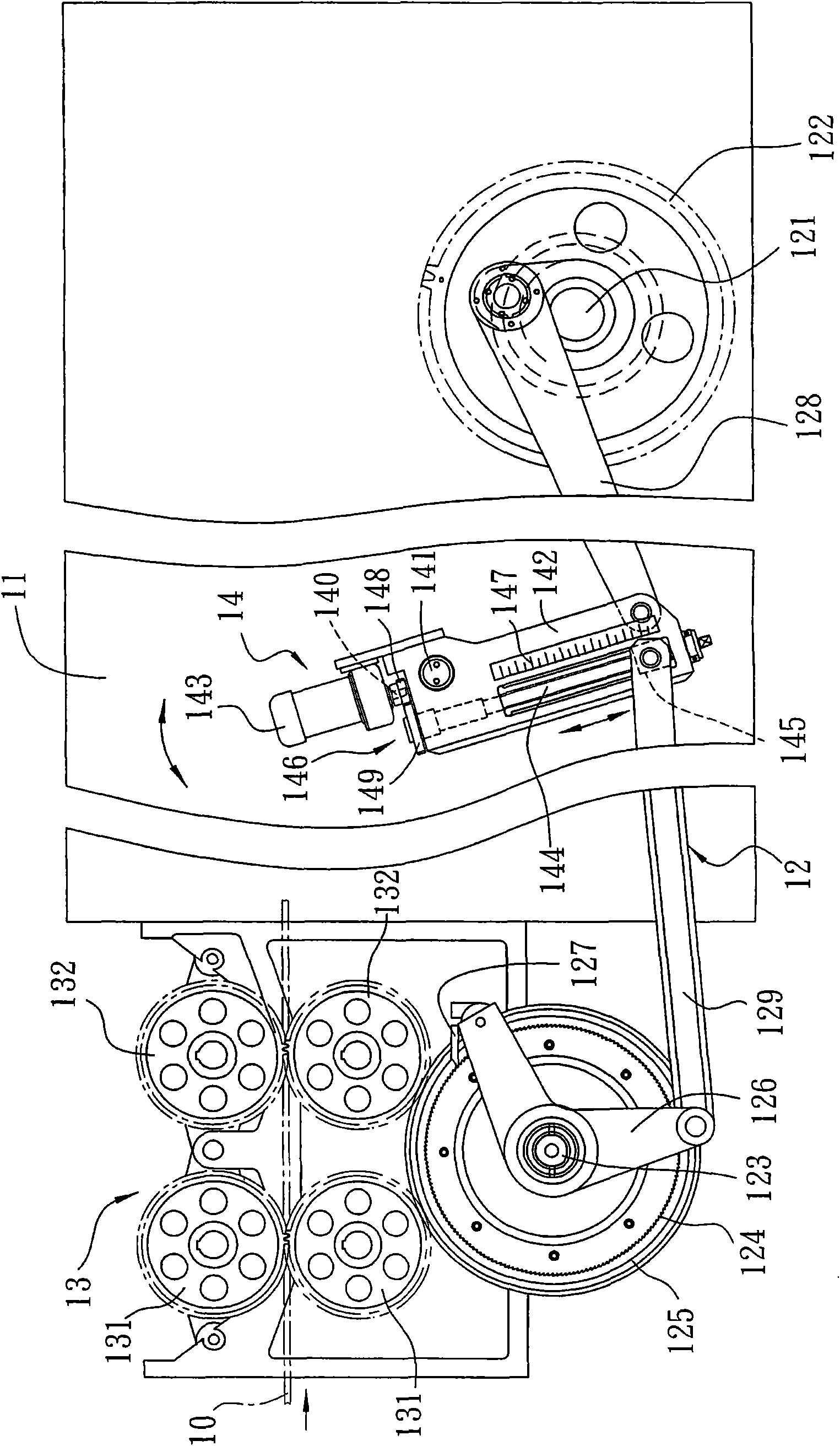

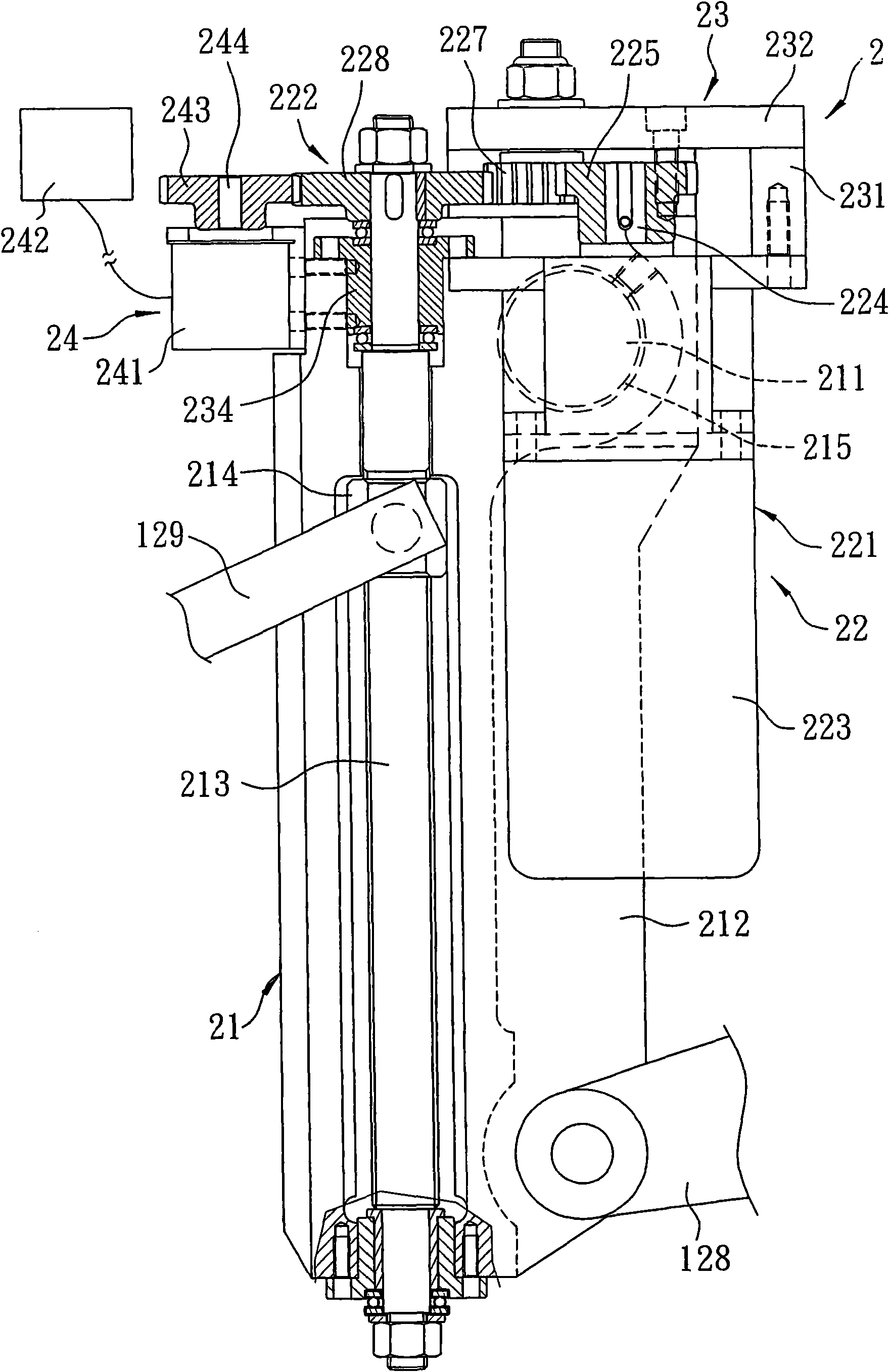

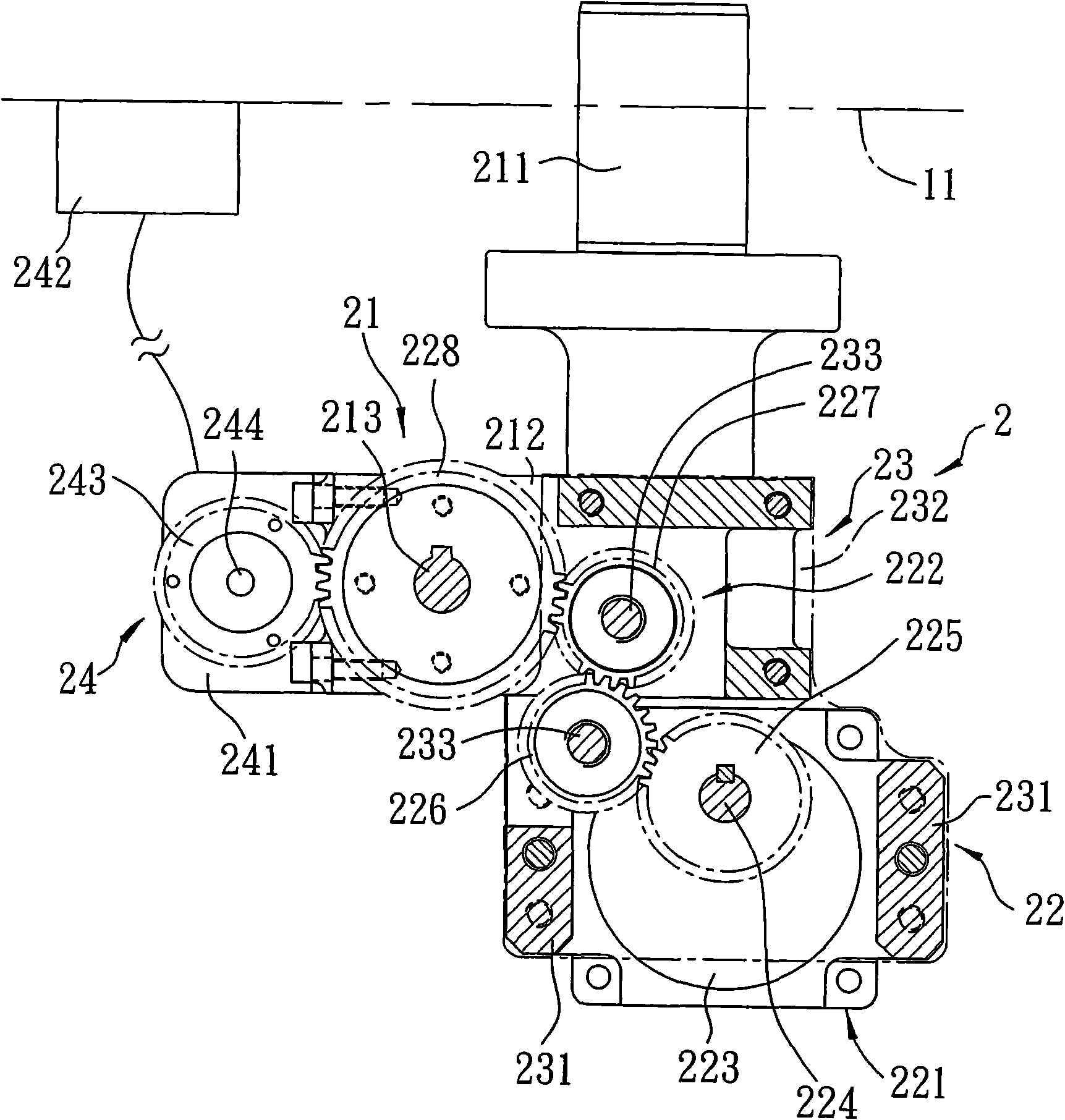

[0021] Such as Figure 2 to Figure 4 As shown, the preferred embodiment of the adjuster 2 of the feeding device for the forging parts forming machine of the present invention, wherein the feeding device is also arranged at the back of a machine table 11 of the forging parts forming machine, and its driving, feeding, etc. The main unit composition, action mechanism and purpose of use etc. are all the same as the background technology (see figure 1 ), and do not belong to the scope of protection of the present invention, and will not be repeated here.

[0022] Therefore, the adjuster 2 of the feeding device for the forging parts forming machine can swing left and right (with figure 2 Direction) is connected between a driving link 128 and a driven link 129 of the feeding device, and includes a bottom that is pivotally connected with the left end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com