Smoke purification equipment and system thereof

A technology for purifying equipment and smog, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, combined devices, etc., can solve the problems of inapplicable smog, purification treatment, smog purification treatment, etc., and achieve improved air intake uniformity and simple equipment structure , the effect of filtering large flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

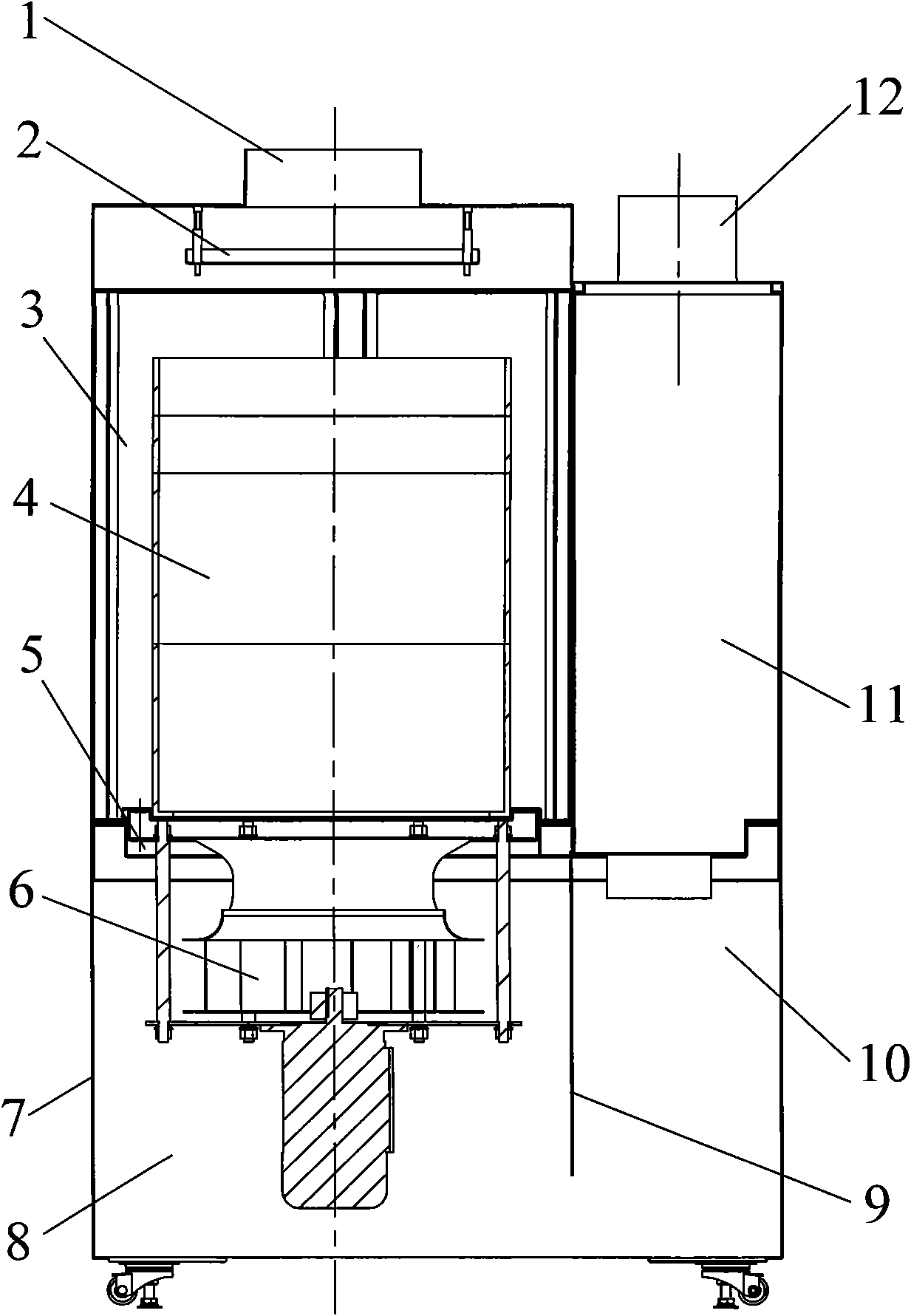

[0020] This embodiment provides a smoke purification device, which is used to purify the smoke generated in the welding of electronic products and mechanical equipment, so as to prevent these harmful smoke from being directly discharged into the operating space or the atmosphere to cause pollution to human health and the environment. Such as figure 1 As shown, the smoke purification equipment specifically includes:

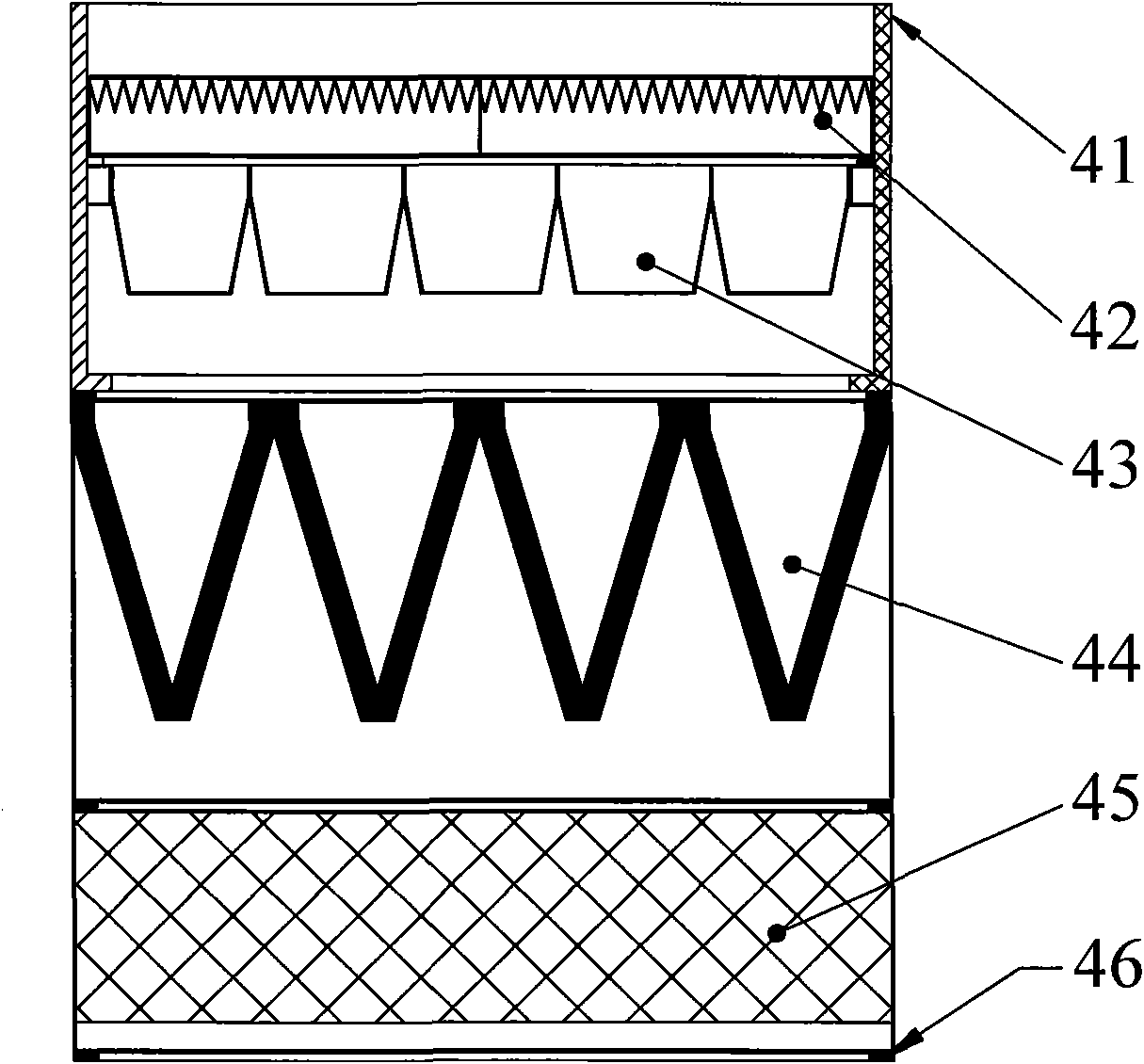

[0021] Box body, air inlet 1, air outlet 12, air inlet pre-filter device 2, combined filter device 4, fan 6, shock-absorbing sealing device 5, air chamber 8, partition 9 and exhaust chamber 10; among them, The air inlet 1 is arranged on the box body, and the air inlet 1 communicates with the combined filter device 4 set in the box through the air intake pre-filter device 2, and the air outlet end of the combined filter device 4 is provided with a fan 6, and the fan 6 passes the vibration reduction The sealing device 5 is fixedly communicated with the air outlet o...

Embodiment 2

[0046] This embodiment provides a smoke purification system, which is a smoke purification system formed on the basis of the smoke purification equipment given in the first embodiment above. Filtration treatment, discharge non-toxic and harmless gas after filtration, reduce the adverse effects of welding gas on human body and environment, such as Figure 5 As shown, the system specifically includes:

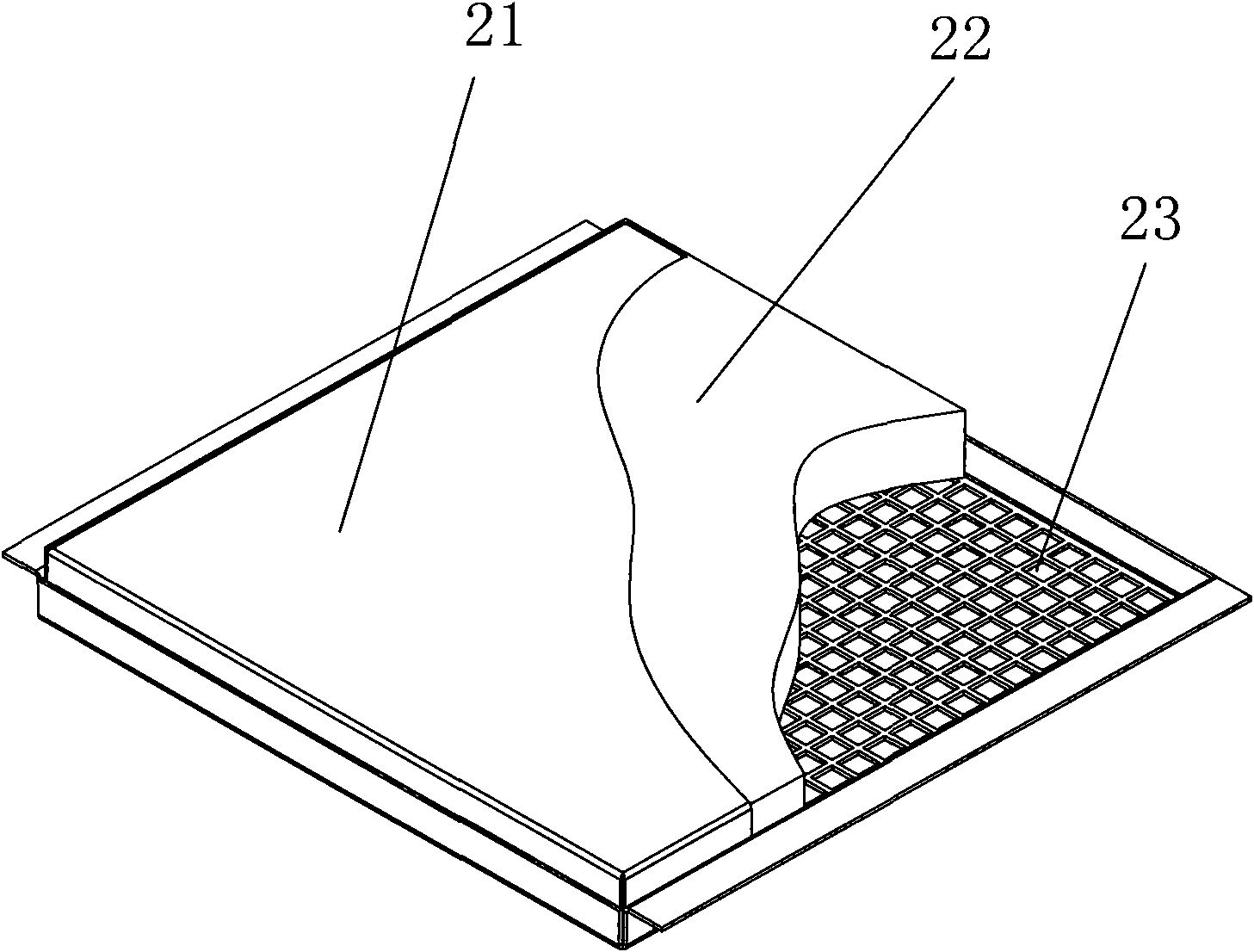

[0047] The welding station, the flue gas receiving device, the connecting pipe, the exhaust pipe, and the smoke purification equipment given in the first embodiment; wherein, the upper end of the welding station is provided with a flue gas receiving device, which is connected to the connecting pipe through the flue gas receiving device, The other end of the connecting pipe is communicated with the air inlet of the smoke purification equipment, and the exhaust port provided on the smoke purification equipment is communicated with the exhaust pipeline. The flue gas receiving devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Filtration accuracy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com