Oscillating device for brush breaker

A swing device and brush cutter technology, which is applied to the chassis of agricultural machinery, agricultural machinery and implements, and hedge trimming equipment, etc., can solve the problem that the working width cannot be adjusted, the suspension position cannot be adjusted horizontally, and the brush cutter cannot be adjusted. Operation and other problems, to achieve the effect of improving cutting efficiency, improving operation efficiency and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

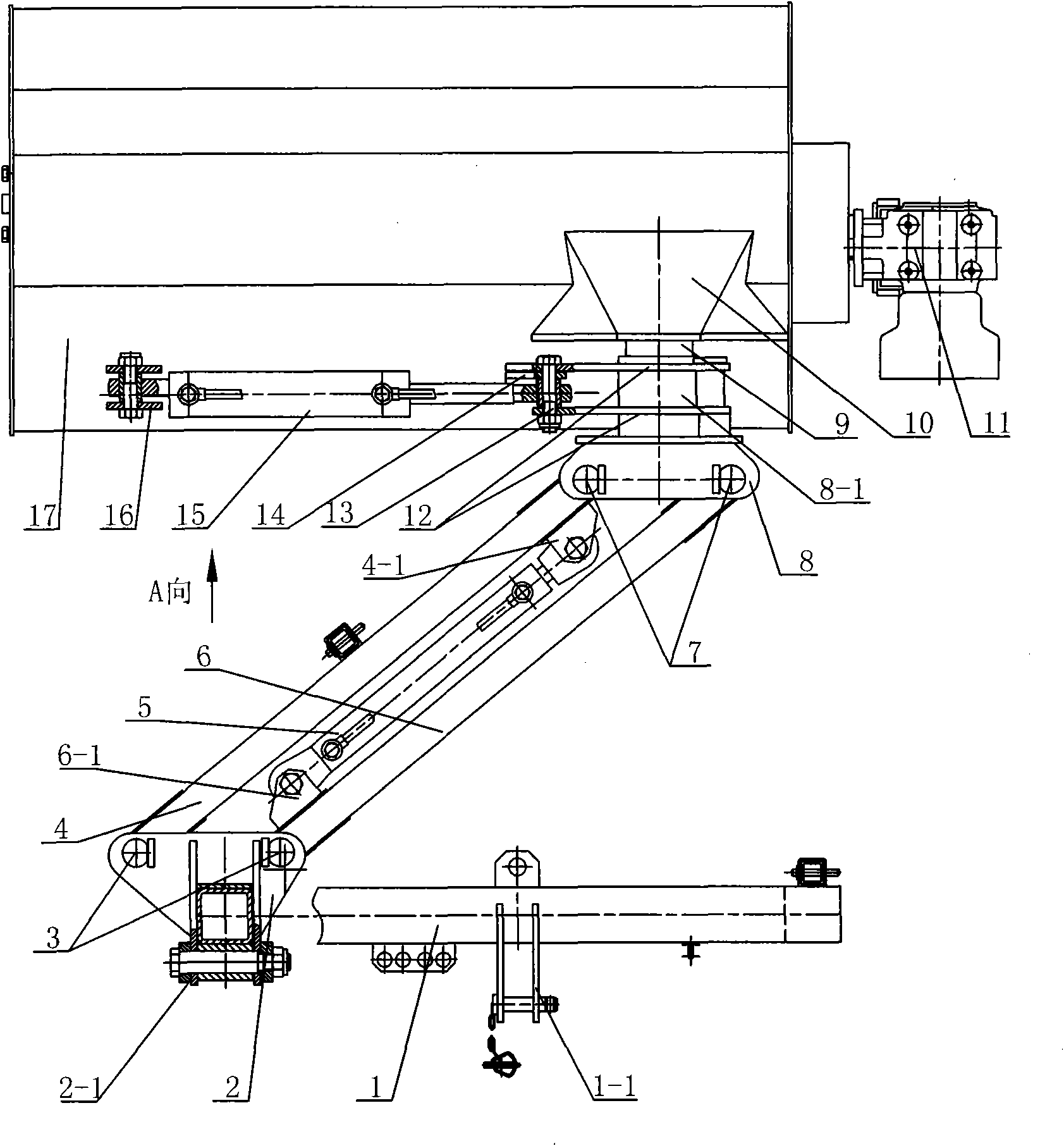

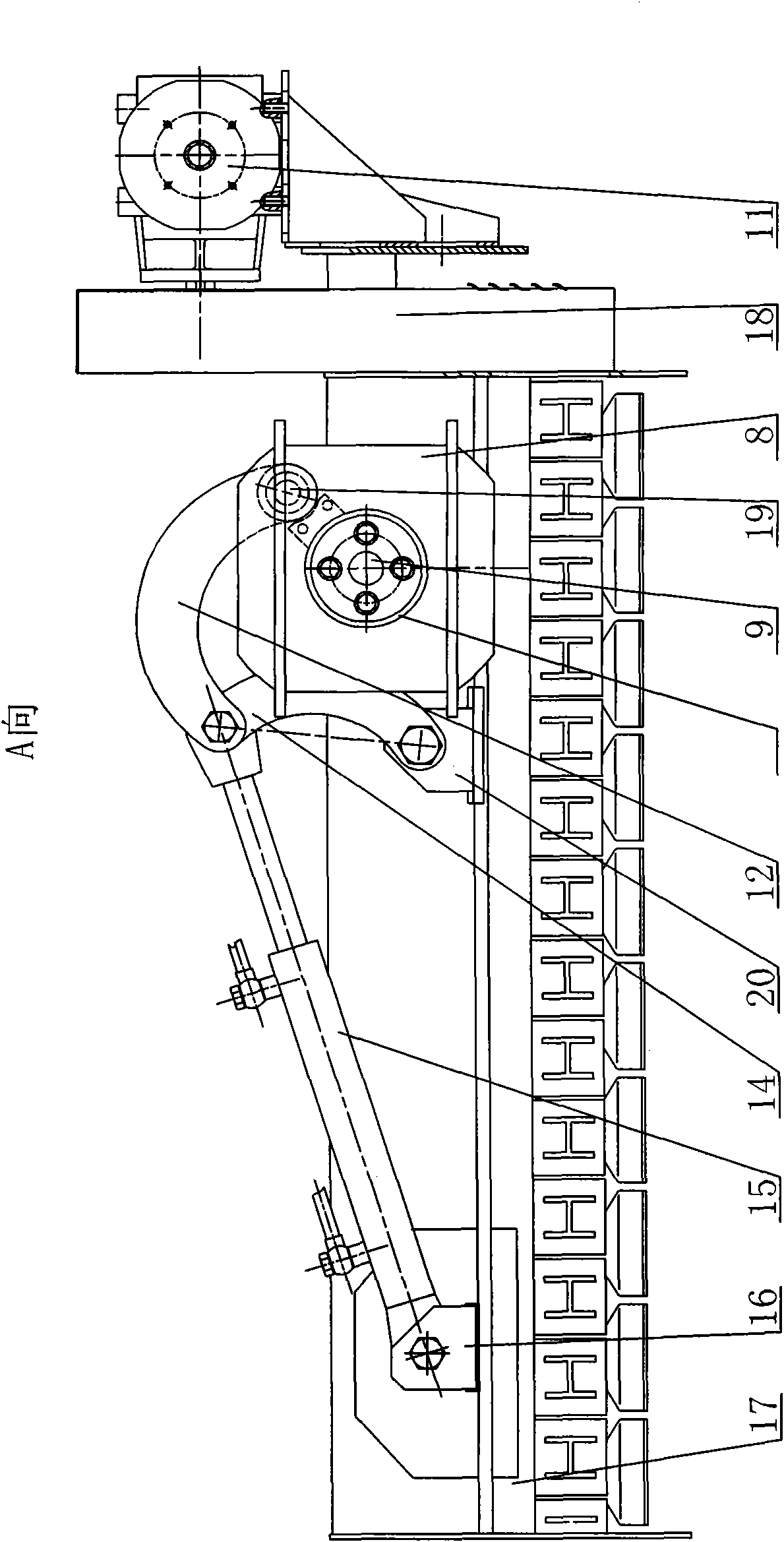

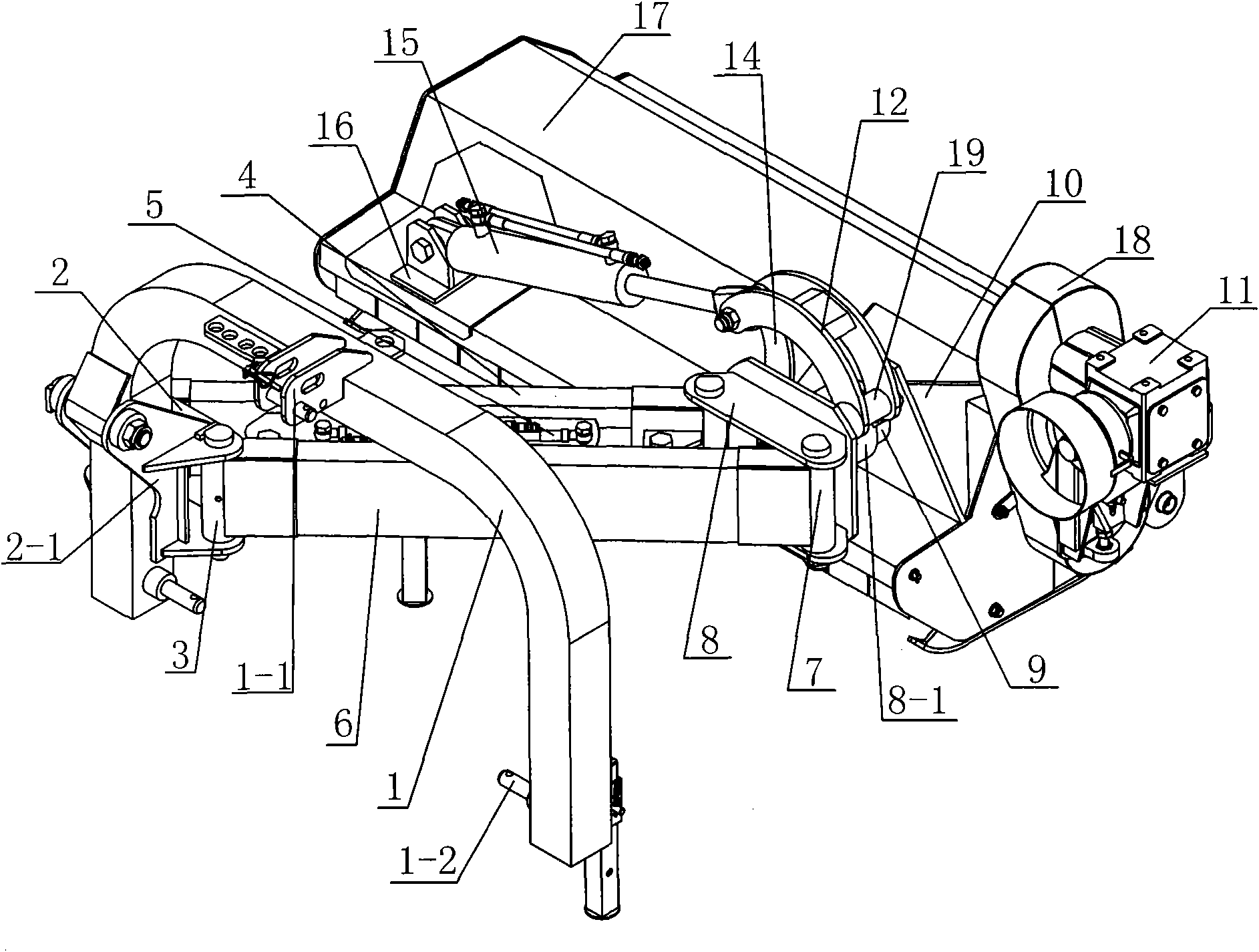

[0011] See Figure 1~3 As shown, the swing device of the brush cutter of the present invention includes a body 17, a deflection mechanism, a swing mechanism and a suspension frame 1, a transmission box and a belt chain transmission mechanism are installed on one side of the body 17, and the power output shaft of the tractor is connected to the The transmission box 11 is connected to transmit the power to the transmission box 11 on the brush cutter, and the knife shaft installed on the body 17 is driven to rotate through the chain-type transmission mechanism 18, so that the knife shaft drives the cutter to rotate to cut shrubs or mow grass Wait for homework.

[0012] See figure 1 , 3 As shown, the swing mechanism of the present invention is a four-bar linkage mechanism composed of the left swing arm 4 and the right swing arm 6 hinged on both sides of the front swing frame 2 and the rear swing frame 8, and the front swing frame 2 and the rear swing frame 8 respectively pass th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com